Method for extracting and purifying alkaloid in plants

A plant alkaloid and plant technology, applied in the field of alkaloid extraction and purification in plants, can solve the problems of cumbersome process flow, loss of effective components, etc., and achieve the effects of less extraction interference, saving intermediate processing links, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

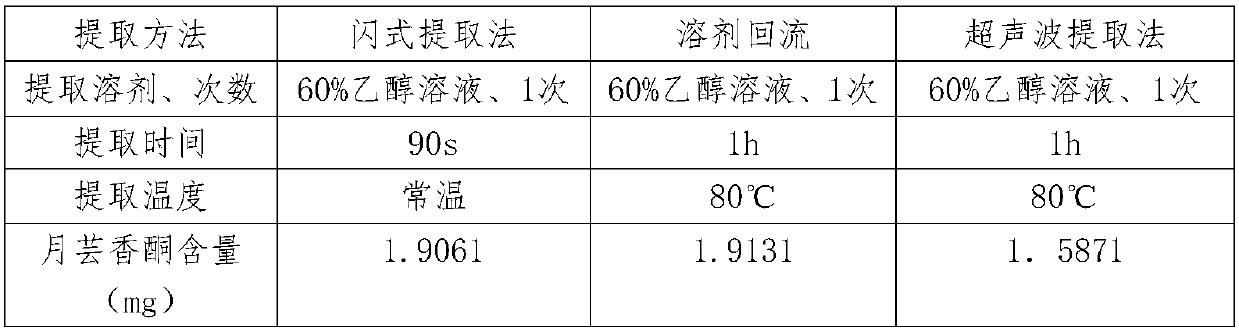

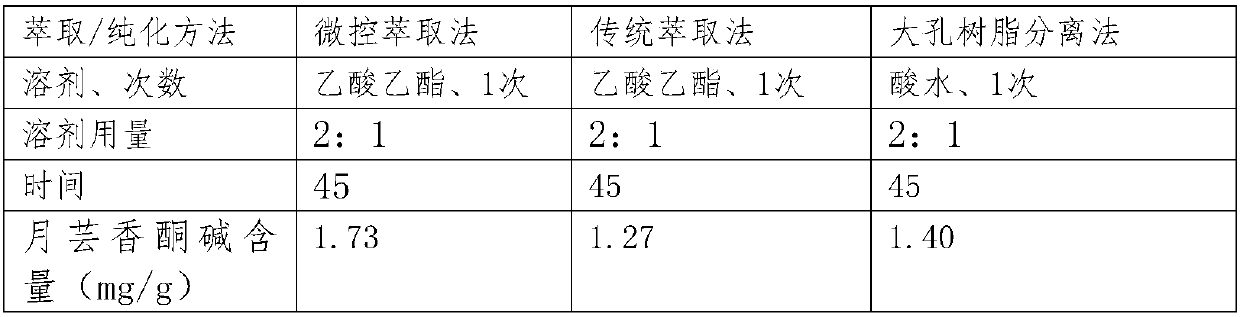

[0058] Embodiment 1: Smelly goat alkaloid extraction

[0059] (1) Take 15g of stinky goat coarse powder that has been dried and crushed to 24 mesh at 40°C, add 450ml of ethanol solution with a volume fraction of 60% and soak for 1h, then use a flash extractor to extract at a voltage of 100V to obtain an extract , get filtrate after filtering, take rutone base as standard substance, detect its content with HPLC;

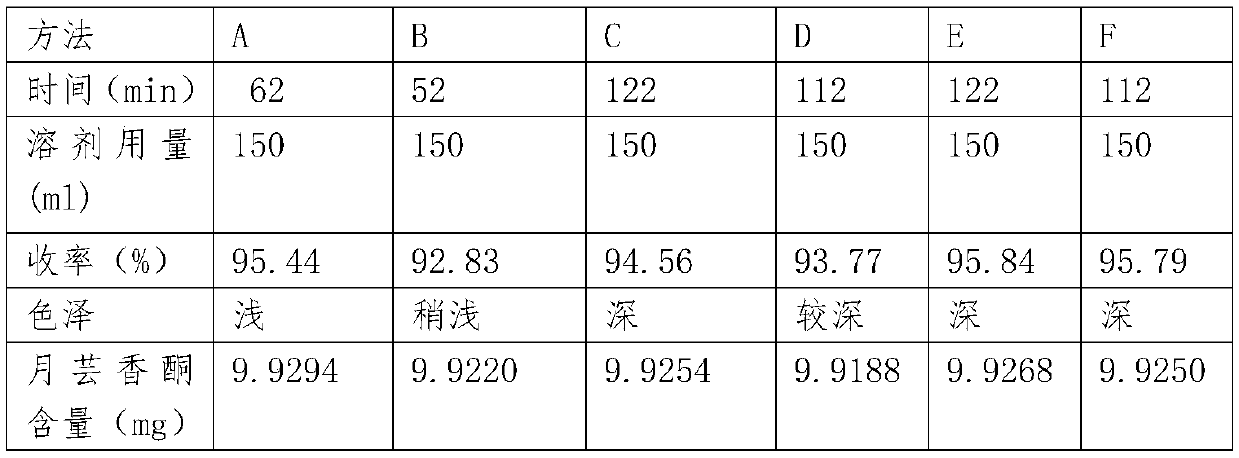

[0060] (2) Rotate the obtained filtrate to dryness to obtain the total extract, weigh 1g and dissolve it with 150ml 2% hydrochloric acid, filter, adjust the pH value of the filtrate to 8.5 with ammonia water, add 75ml of organic solvent ethyl acetate, and place it in a micro-extraction device Carry out micro-controlled extraction;

[0061] (3) After the extract was allowed to stand until the layers were completely separated, the organic layer was taken and evaporated to dryness to obtain the active ingredient total biological alkaloids. The content was detected by HP...

Embodiment 2

[0062] Embodiment 2: lotus leaf alkaloid extraction

[0063] (1) Take 12.5g of lotus leaf coarse powder that has been dried and crushed to 20 mesh at 45°C, add 250ml of ethanol solution with a volume fraction of 80% and soak for 1h, then use a flash extractor to extract at a voltage of 100V to obtain an extract , get the filtrate after filtering, take nuciferine as standard substance, measure its content with ultraviolet spectrophotometry;

[0064] (2) Rotate the obtained filtrate to dryness to obtain the total extract, weigh 1g and dissolve it with 150ml of 2% hydrochloric acid, filter, adjust the pH value of the filtrate to 10 with ammonia water, add 150ml of organic solvent dichloromethane, and place it in a micro-extraction device Carry out micro-controlled extraction;

[0065] (3) After the extract was allowed to stand until the layers were completely separated, the organic layer was taken and evaporated to dryness to obtain the active ingredient total biological alkaloi...

Embodiment 3

[0066] Embodiment 3: Uncaria alkaloid extraction

[0067] (1) Take 12.5 g of Uncaria coarse powder that has been dried and crushed to 24 mesh at 45°C, add 250 ml of ethanol solution with a volume fraction of 70% and soak for 1 hour, then use a flash extractor to extract at a voltage of 100 V to obtain an extract , get filtrate after filtering, take rhynchophylline as standard substance, measure its content with ultraviolet spectrophotometry;

[0068] (2) Rotate the obtained filtrate to dryness to obtain the total extract, weigh 1g and dissolve it with 150ml of 2% hydrochloric acid, filter, adjust the pH value of the filtrate to 8 with ammonia water, add 150ml of organic solvent dichloromethane, and place it in a micro-extraction device Carry out micro-controlled extraction;

[0069] (3) After the extract was allowed to stand until completely separated, the organic layer was taken and evaporated to dryness to obtain the active ingredient, total biological alkaloids. Taking rhy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com