A kind of dull nylon film and preparation method thereof

A nylon film and nylon resin technology, applied in the field of biaxially stretched film and biaxially stretched nylon film, can solve the problems of cumbersome process, poor film matting effect, unstable product quality, etc., to increase the degree of unevenness and realize light weight Effects with excellent quantization effect and matting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a kind of preparation method of dull nylon film, comprises the following steps:

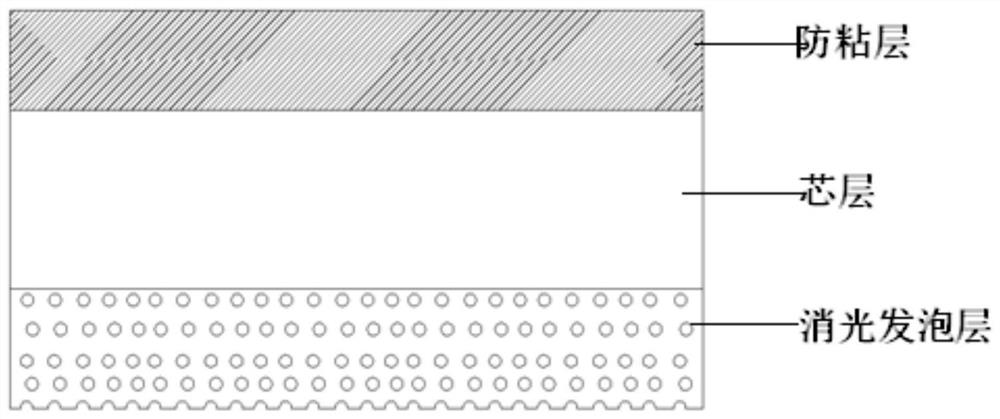

[0035]Put the anti-adhesive layer, core layer and matting foam layer into the respective extruders to melt and extrude, flow through the T-shaped die to the chilled roll to cool the cast sheet, the temperature of the chilled roll is 25 ℃ ~ 30 ℃; wherein, the release layer contains 97 to 99 parts by weight of nylon resin, 0.5 to 2 parts by weight of anti-sticking agent, and 0.5 to 1 part by weight of slippery agent; the core layer contains nylon resin; the matting The foaming layer comprises 91-97 parts by weight of nylon resin, 2-5 parts by weight of foaming agent, 0.5-2 parts by weight of foaming initiator, and 0.5-2 parts by weight of matting powder;

[0036] The cast sheet is treated with hot water in a constant temperature water tank, then the surface moisture is removed, and then it enters the stretching zone of the stretching box for simultaneous s...

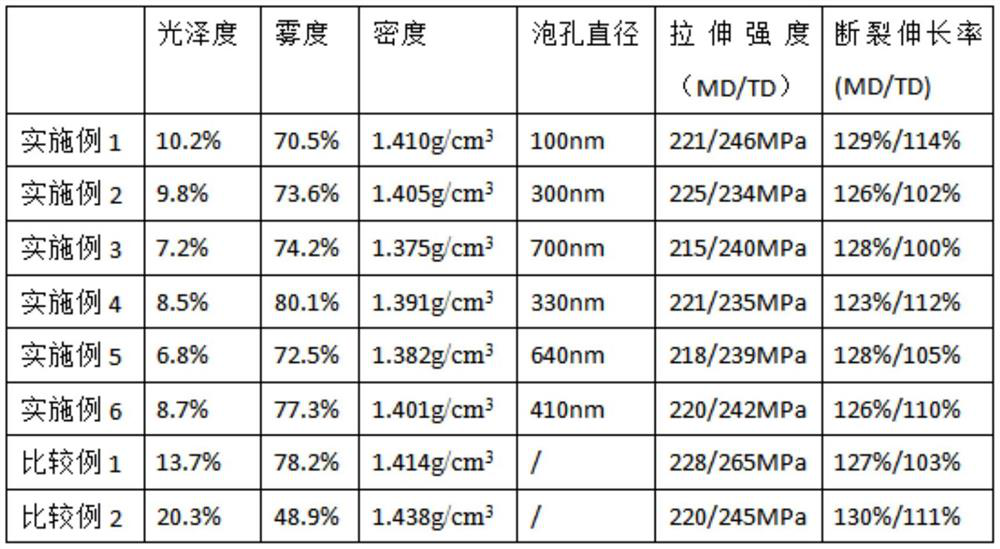

Embodiment 1

[0045] A matte nylon film and its preparation method: the matte nylon film includes an anti-adhesive layer, a core layer and a matte foaming layer. In terms of weight fraction, the release layer contains 99% of nylon resin, 0.5% of release agent, and 0.5% of slippery agent; the core layer contains 100% of nylon resin; the extinction foam layer contains 97% of nylon resin, Foaming agent 2%, foaming initiator 0.5%, matting powder 0.5%.

[0046] Wherein, the nylon resin is nylon 6. The anti-sticking agent is spherical silica. The slippery agent is erucamide. The blowing agent is amine oxalate. The foam initiator is lanthanum sulfate. The matting powder is silicon dioxide.

[0047] The preparation was carried out according to the above preparation method, the light source used was a laser light source with a wavelength of 400 nm, and the irradiation time was 5 s, and the thickness of the obtained film was 15 μm.

Embodiment 2

[0049] A matte nylon film and its preparation method: the matte nylon film includes an anti-adhesive layer, a core layer and a matte foaming layer. In terms of weight fraction, the release layer contains 98% of nylon resin, 1% of release agent, and 1% of slippery agent; the core layer contains 100% of nylon resin; the extinction foam layer contains 95% of nylon resin, Foaming agent 3%, foaming initiator 1%, matting powder 1%.

[0050] Wherein, the nylon resin is nylon 6. The anti-blocking agent is cerium oxide. The slippery agent is oleic acid amide. The foaming agent is ammonium nitrite. The foaming initiator is cerium oxide. The matting powder is silicon carbide.

[0051] According to the above preparation method, the light source used for the preparation is a laser light source with a wavelength of 600 nm, and the irradiation time is 10 s, and the thickness of the obtained film is 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com