Low-gloss low-warpage soft-touch-feeling vehicle polypropylene composition as well as preparation method and application thereof

A polypropylene composition and low warpage technology, applied in the field of polypropylene polymer materials, can solve the problems of unavailability, low gloss and high strength, and achieve the effect of soft touch and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

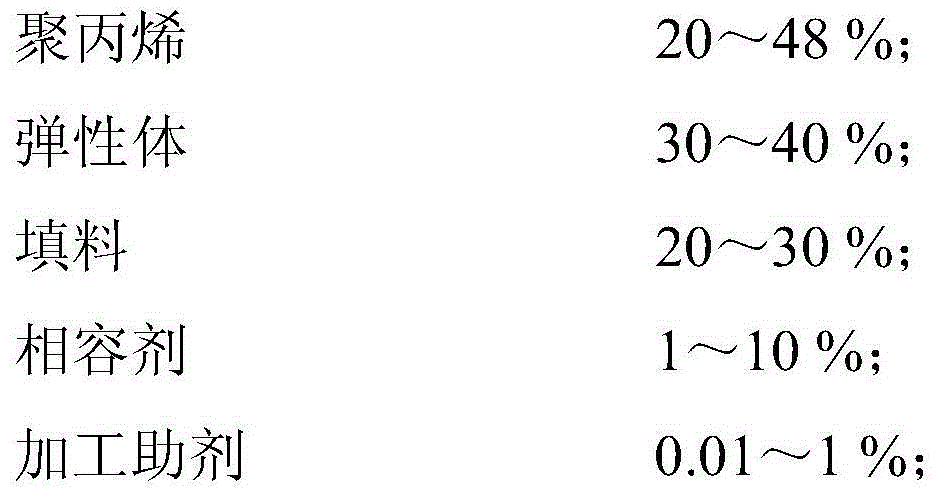

Method used

Image

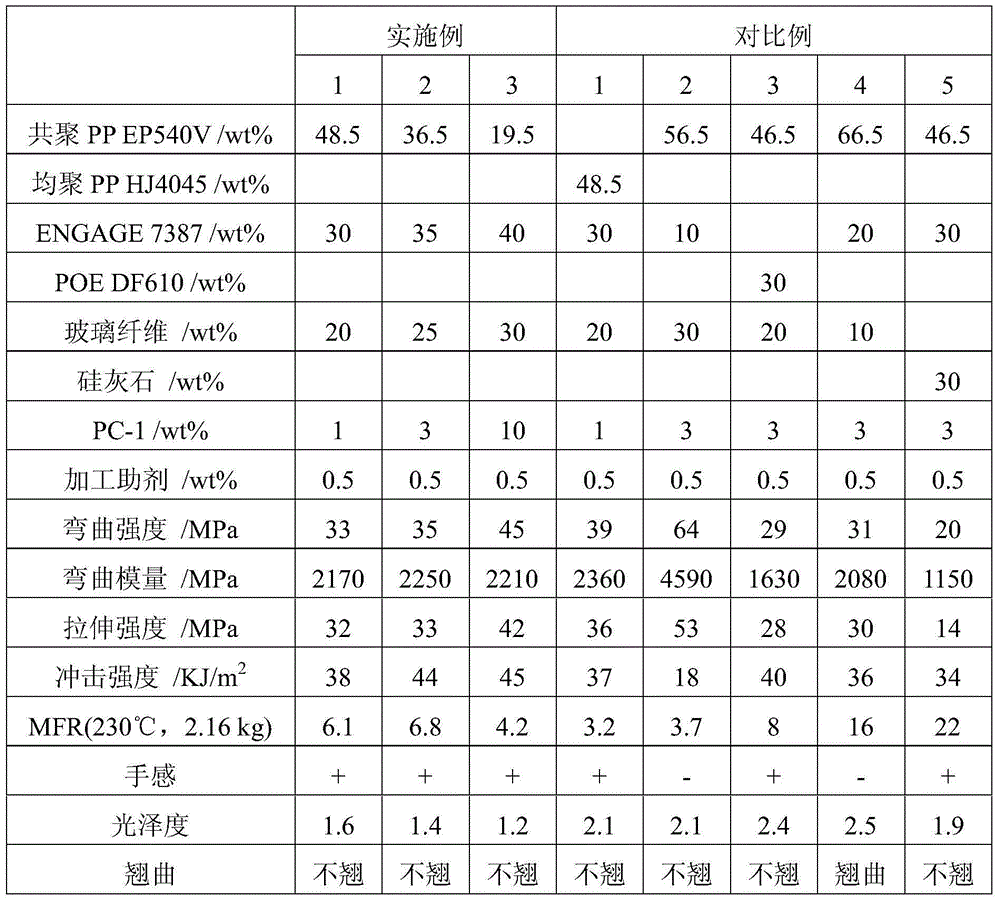

Examples

Embodiment 1

[0040] Example 1: Preparation of low-gloss, low-warp, soft-touch automotive polypropylene composition

[0041] 48.5wt% copolymerized PP EP540V, 30wt% elastomer ENGAGE 7387, 1wt% compatibilizer PC-1 and 0.5wt% processing aid (0.1wt% each of antioxidant 1010 and antioxidant 168, light stabilizer UV- 3808PP5 0.3wt%) was added to a high-speed mixer and mixed for 1 to 3 minutes at a speed of 1000 to 2000 rpm to obtain a premix; the premix was added at the main feeding port of the twin-screw extruder, 20wt% glass The fibers are added at the side feeding port, the temperature of each zone of the screw is 190-230°C, and the vacuum granulation can obtain the low-gloss, low-warp, soft-touch polypropylene composition for vehicles of the present invention.

Embodiment 2

[0042] Example 2: Preparation of low-gloss, low-warp, soft-touch automotive polypropylene composition

[0043]36.5wt% copolymerized PP EP540V, 35wt% elastomer ENGAGE 7387, 3wt% compatibilizer PC-1 and 0.5wt% processing aid (0.1wt% each of antioxidant 1010 and antioxidant 168, light stabilizer UV- 3808PP5 0.3wt%) was added to a high-speed mixer and mixed for 1 to 3 minutes at a speed of 1000 to 2000 rpm to obtain a premix; the premix was added to the main feeding port of the twin-screw extruder, 25wt% The fibers are added at the side feeding port, the temperature of each zone of the screw is 190-230°C, and the vacuum granulation can obtain the low-gloss, low-warp, soft-touch polypropylene composition for vehicles of the present invention.

Embodiment 3

[0044] Example 3: Preparation of low-gloss, low-warp, soft-touch automotive polypropylene composition

[0045] 19.5wt% copolymerized PP EP540V, 40wt% elastomer ENGAGE 7387, 10wt% compatibilizer PC-1 and 0.5wt% processing aid (0.1wt% each of antioxidant 1010 and antioxidant 168, light stabilizer UV- 3808PP5 0.3wt%) was added to a high-speed mixer and mixed for 1 to 3 minutes at a speed of 1000 to 2000 rpm to obtain a premix; the premix was added at the main feeding port of the twin-screw extruder, 30wt% The fibers are added at the side feeding port, the temperature of each zone of the screw is 190-230°C, and the vacuum granulation can obtain the low-gloss, low-warp, soft-touch polypropylene composition for vehicles of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com