Polydicyclopentadiene/high-polymer elastomer IPN (interpenetrating polymer network) high-polymer alloy material and preparation method thereof

A technology of polydicyclopentadiene and polymer alloy, which is applied in the field of catalysts, can solve problems such as the absence of alloys, and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

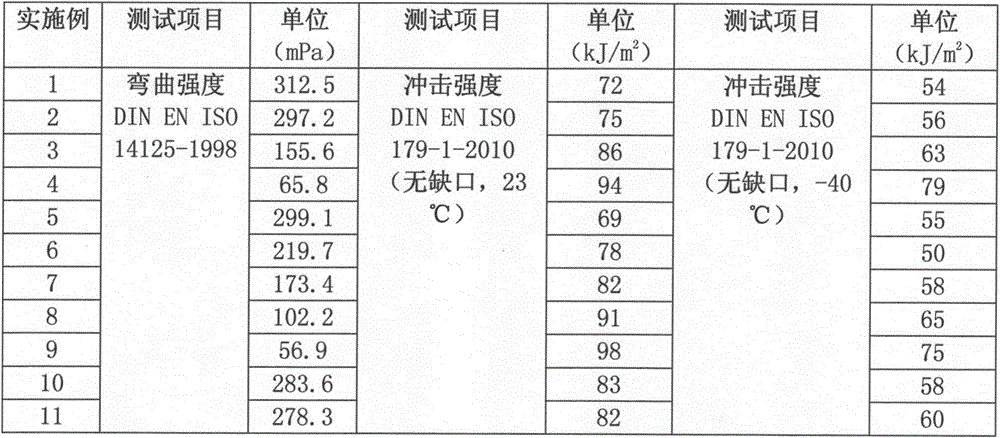

Examples

Embodiment 1

[0029] A kind of IPN polymer alloy material of PDCPD / SBS

[0030] 1. Raw materials

[0031] DCPD, SBS resin, Grubbs'I generation ruthenium catalyst solution (mass concentration is 30%)

[0032] 2. Preparation method:

[0033] Step 1): put the SBS resin into the dicyclopentadiene liquid at 80°C and stir for 5 hours to dissolve, and the mass percentage of the SBS resin and dicyclopentadiene is 1%;

[0034] Step 2): Add a ruthenium catalyst solution to the dicyclopentadiene solution of the elastomer obtained in step 1), the mass concentration of the active ingredient of the ruthenium catalyst and dicyclopentadiene is 0.1%, and then inject the mixed solution into the mold to react and solidify That is, the mold temperature is 60°C.

Embodiment 2

[0036] A kind of IPN polymer alloy material of PDCPD / SBS

[0037] 1. Raw materials

[0038] DCPD, SBS resin, Grubbs'I generation ruthenium catalyst solution (mass concentration is 40%)

[0039] 2. Preparation method:

[0040] Step 1): put the SBS resin into the dicyclopentadiene liquid at 80°C and stir for 5 hours to dissolve, and the mass percentage of the SBS resin and dicyclopentadiene is 5%;

[0041] Step 2): Add a ruthenium catalyst solution to the dicyclopentadiene solution of the elastomer obtained in step 1), the mass concentration of the active ingredient of the ruthenium catalyst and dicyclopentadiene is 0.1%, and then inject the mixed solution into the mold for reaction and curing That is, the mold temperature is 60°C.

Embodiment 3

[0043] A kind of IPN polymer alloy material of PDCPD / SBS

[0044] 1. Raw materials

[0045] DCPD, SBS resin, Grubbs'I generation ruthenium catalyst solution (mass concentration is 50%)

[0046] 2. Preparation method:

[0047] Step 1): put the SBS resin into the dicyclopentadiene liquid at 80°C and stir for 5 hours to dissolve, and the mass percentage of the SBS resin and dicyclopentadiene is 35%;

[0048]Step 2): Add a ruthenium catalyst solution to the dicyclopentadiene solution of the elastomer obtained in step 1), the mass concentration of the active ingredient of the ruthenium catalyst and dicyclopentadiene is 0.1%, and then inject the mixed solution into the mold for reaction and curing That is, the mold temperature is 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com