A kind of waterproofing agent for mortar concrete and preparation method thereof

A technology for mortar concrete and waterproofing agent, which is applied in the field of building materials, can solve the problems of time resistance strength to be improved, complex production and construction processes, non-compliance with environmental protection requirements, etc., and achieves the effects of easy packaging and transportation, improved compactness, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

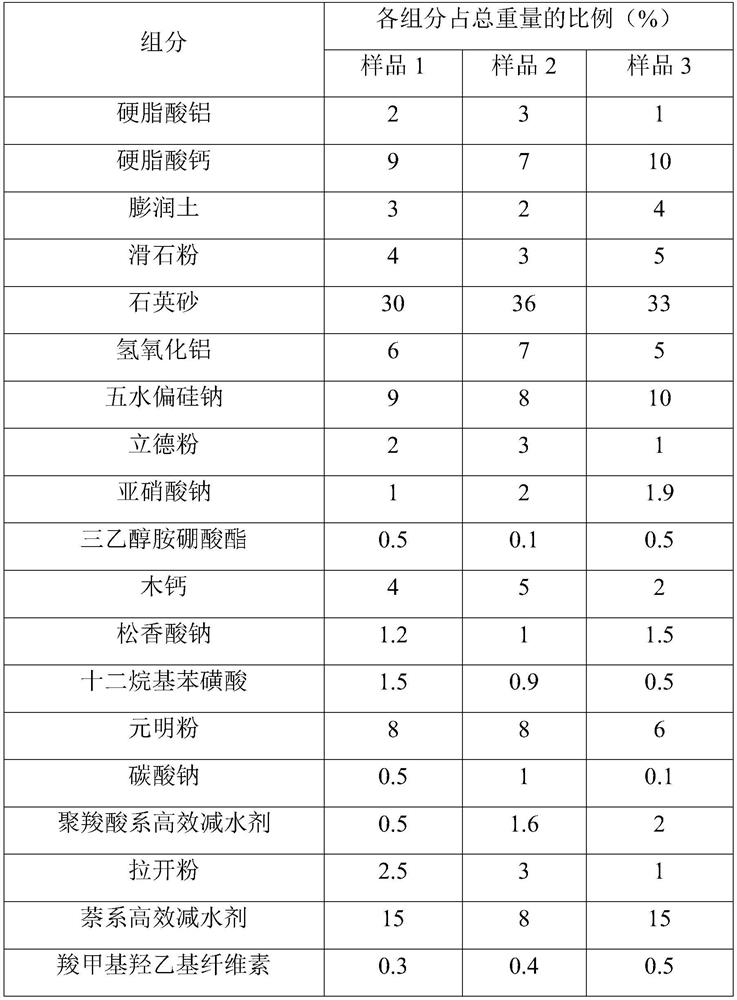

[0046] The total weight of each sample was 1000 g, and each of the components of the components were weighted according to Table 1, and the various components were mixed with dry powder, i.e., the water repeater of the mortar concrete 1 to 3. The specific formula is invited to see Table 1 below. The raw materials used are commercially available. Among them, the naphthalene high-efficiency water reduction is the HSN naphthalene high-efficiency water reducer of Qingdao Hongxia Polymer Material Co., Ltd. (mainly β-naphthalene sulfate), and the polycarboxylic acid-based high-efficiency water reduction is Shanghai. Qso Industrial Co., Ltd. QS Polycarboxylic acid high-performance water reduction (main component is a monomethyl ether ester of methyl methacrylate).

[0047] Table 1 Embodiment 1 to 3 Group Distribution Plan

[0048]

Embodiment 4

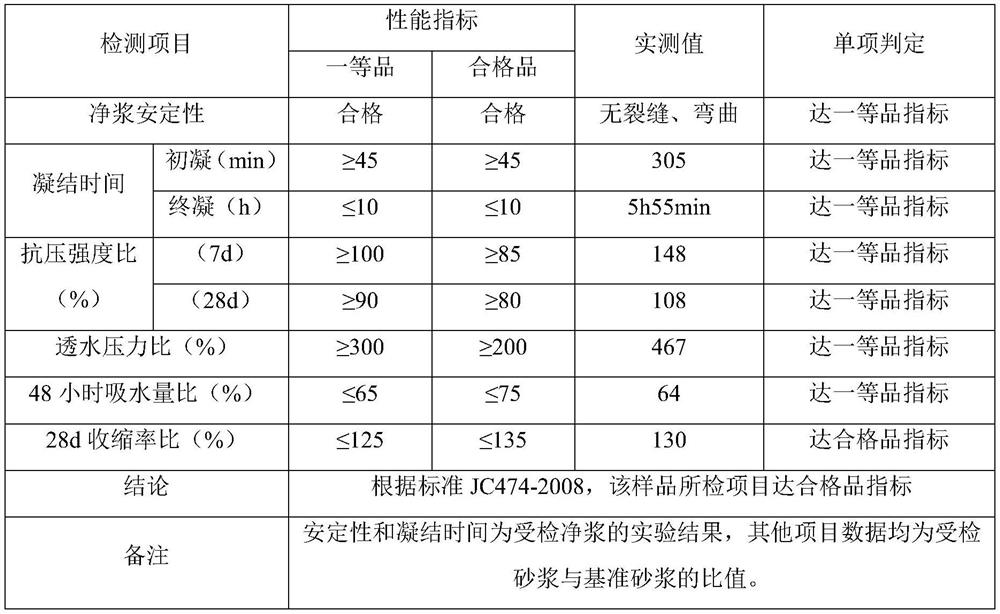

[0050] The water repeater of the mortar concrete prepared in Example 1 was tested by Sichuan Construction Engineering Quality Testing Center. The performance indicators reached or exceeded the national standard JC474-2008 standard. The main performance indicators were shown in Table 2. Looking:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com