Preparation method of fluoro-compound gel polymer electrolyte membrane and lithium ion battery

A gel polymer and electrolyte membrane technology, applied in the field of lithium-ion batteries, can solve the problems of unsuitable industrial application, low conductivity, limited effect, etc., to improve room temperature ion conductivity, high liquid absorption rate, and good affinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] The fluoropolymer gel polymer electrolyte membrane described in this embodiment is a copolymer electrolyte membrane of a gelable monomer and a fluorine-containing vinyl monomer, and the preparation method includes the following steps:

[0032] Step 1: In parts by weight, add 5-50 parts of fluorine-containing vinyl monomers, 40-80 parts of gelable monomers, and 0-10 parts of polyethylene glycol methacrylate-based monomers into 100-300 parts of In the solvent, keep nitrogen or inert gas atmosphere, stir at 100~800r / min speed for 10min-120min, then add 0.05~1.00 parts of initiator, then react at 60℃~110℃ for 5~48h, and obtain after purification treatment polymer A;

[0033] Step 2: In parts by weight, add 30-80 parts of polymer A and 0-20 parts of fillers into 100-300 parts of solvent, under dry nitrogen or inert gas atmosphere, stir at a rotational speed of 100-800 r / min, and stir. 1~10h, then add 0~2.00 parts of hydroxyl cross-linking agent into the mixing system, the m...

Embodiment 1

[0046] A fluoropolymer gel polymer electrolyte membrane is a copolymer electrolyte membrane of a gelable monomer and a fluorine-containing vinyl monomer, and its preparation method comprises the following steps:

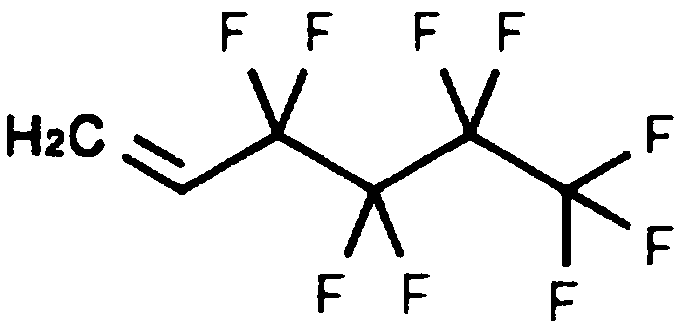

[0047] Step 1: In parts by weight, 3 parts containing 1H, 1H, 2H-perfluoro-1-hexene, 2 parts octafluoropentyl methacrylate, 50 parts polyethylene glycol methyl ether acrylate, 30 parts Methyl methacrylate, 2 parts of polyethylene glycol methyl methacrylate with a molecular weight of 300, and 1 part of polyethylene glycol monoallyl ether with a molecular weight of 2400 were added to 100 parts of toluene, and nitrogen was continuously passed through at 800 r / Stir for 10 min at a rotating speed of 1 min, then add 1.00 parts of azobisisobutyronitrile, and then react at 60°C for 48 h. After purification, polymer A is obtained;

[0048] Step 2: In parts by weight, add 80 parts of polymer A, 8 parts of nano-silicon dioxide, 8 parts of lithium titanate, and 4 parts of lithi...

Embodiment 2

[0052] A fluoropolymer gel polymer electrolyte membrane is a copolymer electrolyte membrane of a gelable monomer and a fluorine-containing vinyl monomer, and its preparation method comprises the following steps:

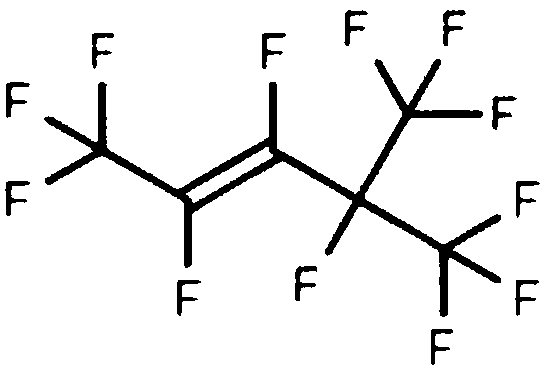

[0053] Step 1: In parts by weight, 20 parts containing 4,4,5,6,6,6-octafluoro-2-hexene, 30 parts of hexafluorobutyl methacrylate, 30 parts of isobutyl methacrylate ester, 10 parts of polyethylene glycol methyl ether methacrylate, 1 part of polyethylene glycol methyl methacrylate with a molecular weight of 2500, 5 parts of polyethylene glycol monoallyl ether with a molecular weight of 100, and added 300 parts of benzene , continue to pass argon, stir at 100r / min for 120min, then add 0.05 part of benzoyl peroxide, then react at 110°C for 36h, and obtain polymer A after purification;

[0054] Step 2: In parts by weight, add 30 parts of polymer A, 5 parts of nano aluminum oxide, 4 parts of lithium aluminum titanate phosphate, and 2 parts of lithium lanthanum tantalate in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com