Wafer grinding and polishing method and corresponding wafer

A technology of wafer and grinding liquid, which is applied in the field of wafer grinding and polishing, and can solve the problems of wafer thickness reduction, affecting wafer grinding quality, and wafer warpage. Achieve the effect of eliminating severe warpage, releasing stress and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] At present, for some wafers with relatively hard materials, during the grinding process, when the grinding liquid configured by aluminum oxide with a diameter of 5 μm is used to grind the wafers, it is very difficult to grind, and it is almost impossible to grind. Easily splinters. At the same time, the stress generated during the grinding process is too large, and the wafer is severely warped or even cracked when it is unloaded from the fixture. In the process of removing impurities by heating chemicals, it is also easy to cause the wafer to break.

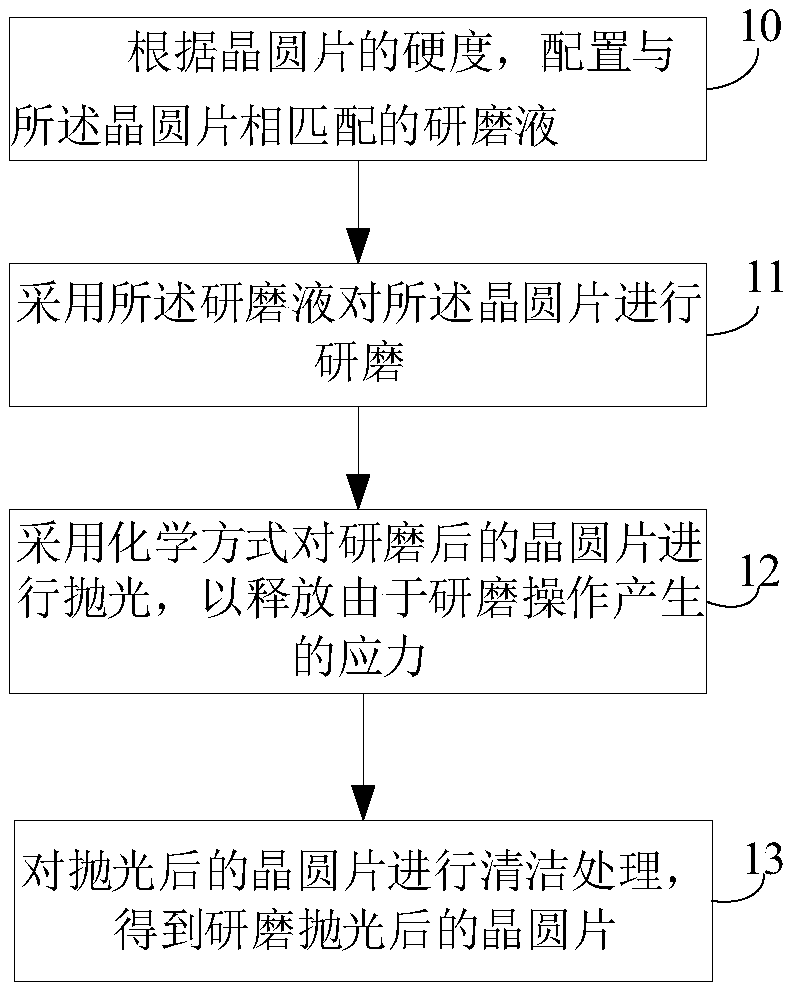

[0036] In order to solve the foregoing problems, an embodiment of the present invention provides a method for grinding and polishing a wafer. The grinding and polishing method configures a suitable grinding liquid according to the hardness of the wafer to ensure the removal rate of the grinding and achieve the goal of thinning the wafer. Effect. Since the hardness of the grinding liquid and the wafer match each other, not...

Embodiment 2

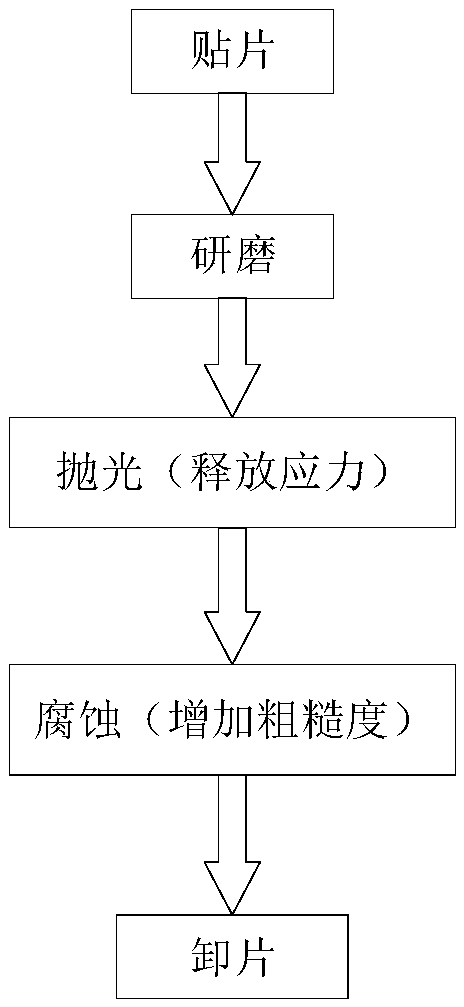

[0055] Aiming at the existing application scenarios, the inventor has verified through batch implementation, based on the grinding and polishing method of the wafer in embodiment 1, provided a set of better parameter combinations, the type of solution, the concentration of the solution, the time of polishing And the associated constraints such as corrosion time are further limited to be suitable for industrial production and improve the yield of products. details as follows:

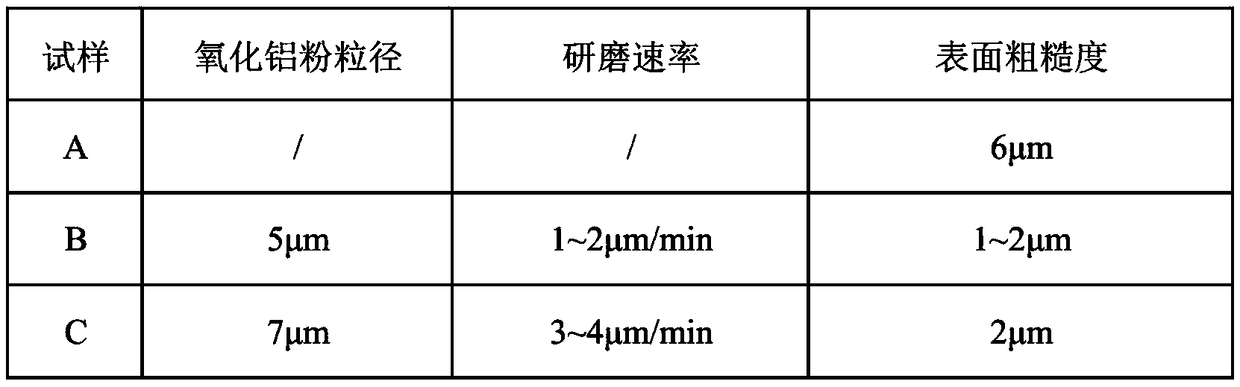

[0056] In this embodiment, the composition of the wafer includes at least one of gallium arsenide or iron-doped indium phosphide, the final size of the wafer after grinding is about 150 μm, and the grinding liquid is composed of aluminum oxide, grinding It is made by mixing oil and water in a certain proportion.

[0057] Since the diameter of aluminum oxide in the grinding liquid has a great influence on the grinding rate of hard materials, the larger the particle size, the faster the grinding removal r...

Embodiment 3

[0065] Corresponding to the above-mentioned embodiment 1 and embodiment 2, the embodiment of the present invention further provides a wafer, which is manufactured according to the grinding and polishing method of the above-mentioned embodiment 1 or embodiment 2.

[0066] For the specific process of the grinding and polishing method of the wafer, please refer to Figure 1 ~ Figure 4 and related text descriptions, which will not be repeated here.

[0067] In the embodiment of the present invention, since the hardness of the grinding fluid and the wafer match each other, not only the grinding quality can be ensured, but also the grinding efficiency can be improved. On the other hand, using chemical polishing liquid to polish the wafer can effectively release the stress generated during the grinding process, eliminate the serious warping of the wafer, and ensure the flatness of the wafer, thereby ensuring the subsequent solution. The physical test can be carried out successfully....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com