Method for manufacturing environment-friendly household building material board by using yellow top chrysanthemum straws and birch shavings

An environmentally friendly technology, applied in textiles and papermaking, pulping with inorganic alkalis, papermaking, etc., can solve the problems of no economical value, difficulty in manual removal, and difficulty, and achieve improved halogen resistance and enhanced effect. Good, the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

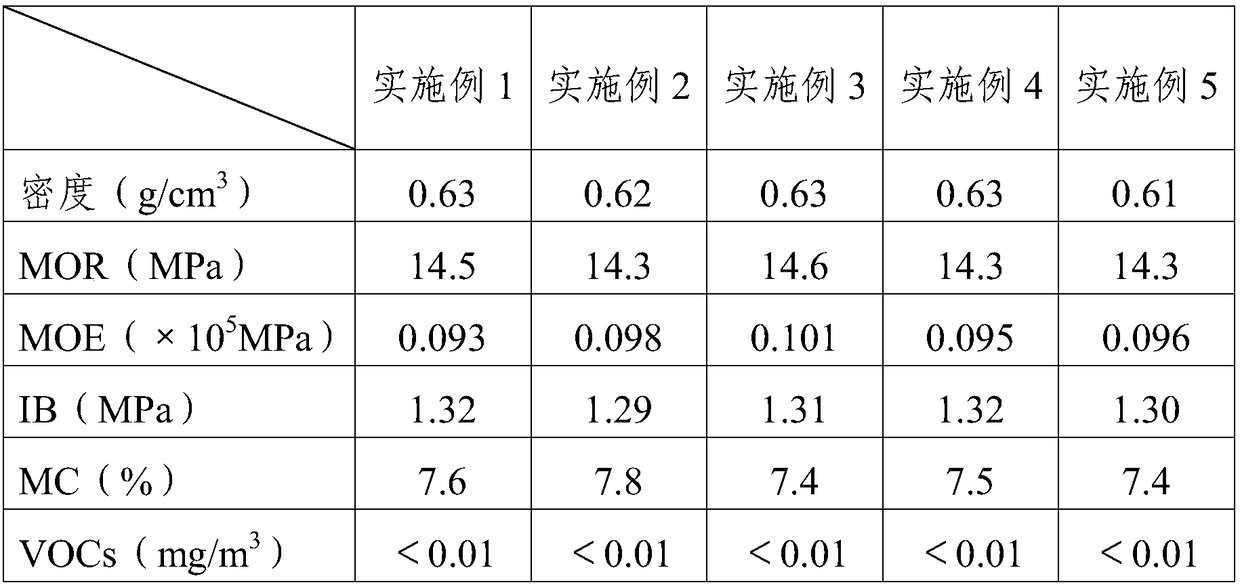

Examples

Embodiment 1

[0030] A method for manufacturing an environment-friendly home improvement building material board by using chrysanthemum stalks and birch shavings, comprising the following steps:

[0031] (1) After drying the chrysanthemum stalks, pulverize them through an 80-mesh sieve with a pulverizer, immerse them in a sodium hydroxide solution with a mass concentration of 1.2% for 8 hours, take them out and drain them, and then immerse them in an acetic acid solution with a mass concentration of 1% for 4.5 hours. After drying until the water content is 16%, it is added to the gas explosion device through the feed port, and the water vapor at 185°C enters the gas explosion device from the steam pipe, pressurized to 7MPa, kept for 3 minutes after heat preservation and pressure release, and exploded to obtain Chrysanthemum chrysanthemum Powder;

[0032] (2) Grind the birch wood shavings to a length of 1-2mm and a width of 0.1-0.5mm. At room temperature, first soak them in a hydrogen peroxi...

Embodiment 2

[0036] A method for manufacturing an environment-friendly home improvement building material board by using chrysanthemum stalks and birch shavings, comprising the following steps:

[0037] (1) After drying the chrysanthemum stalks, crush them through an 80-mesh sieve with a pulverizer, immerse them in a sodium hydroxide solution with a mass concentration of 0.5% for 10 hours, take them out and drain them, and then immerse them in an acetic acid solution with a mass concentration of 1.2% for 6 hours, and let them air naturally After drying until the water content is 15%, it is added into the gas explosion device through the feed port, and the water vapor at 180°C enters the gas explosion device through the steam pipe, pressurized to 8MPa, kept at the pressure for 3 minutes, and then released and exploded to obtain yellow top inulin body;

[0038] (2) Grind the birch shavings to a length of 1-2 mm and a width of 0.1-0.5 mm. At room temperature, first soak them in a hydrogen per...

Embodiment 3

[0042] A method for manufacturing an environment-friendly home improvement building material board by using chrysanthemum stalks and birch shavings, comprising the following steps:

[0043] (1) After drying the chrysanthemum stalks, pulverize them through an 80-mesh sieve with a pulverizer, immerse them in a 0.8% sodium hydroxide solution for 5 hours, take them out and drain them, and then immerse them in a 1.1% acetic acid solution for 5.5 hours. After drying until the water content is 18%, it is added into the gas explosion device through the feed port, and the water vapor at 180°C enters the gas explosion device from the steam pipe, pressurized to 6.5MPa, kept for 3 minutes after heat preservation and pressure release, and exploded to obtain Yellow top chrysanthemum powder;

[0044] (2) Grind the birch shavings to a length of 1-2 mm and a width of 0.1-0.5 mm. At room temperature, first soak them in a hydrogen peroxide solution with a mass concentration of 15% for 2 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com