Environment-friendly toughening nano-cellulose-polylactic acid biodegradable material and preparation method thereof

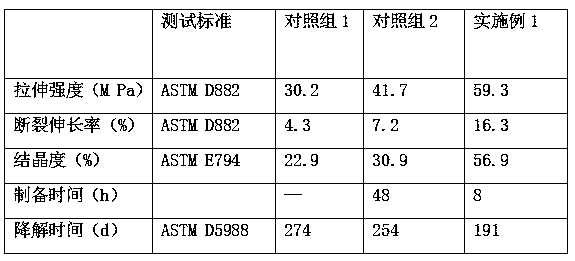

A biodegradable material and nanocellulose technology, applied in the field of polymer processing, can solve the problems of long time for material preparation, poor nanocellulose dispersibility, etc., and achieve excellent interface compatibility, good dispersion performance, and excellent elongation at break. and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of environmentally friendly toughened nanocellulose-polylactic acid biodegradable material

[0029] The environmentally friendly and toughened nanocellulose-polylactic acid biodegradable material prepared in this example includes the following components in weight percentage: 77% polylactic acid, 4% microfibrous cellulose, 16% modifier, and the balance is auxiliary agent In the above-mentioned modifying agent, the mass ratio of glyceryl triacetate and polyvinyl alcohol is 1:1, and the mass percent of polyvinyl alcohol in polyvinyl alcohol aqueous solution is 1% auxiliary agent is made of Y-aminopropyltriethylsilane, Cetyltrimethylammonium bromide, talc powder, and polyethylene wax are obtained by mixing sequentially at a mass ratio of 3:2:1:1.5; wherein, the preparation method of microfibrous cellulose refers to the method disclosed in patent CN105622766B.

[0030] The preparation method is as follows:

[0031] 1) Prepare 1000ml of microfibrous ce...

Embodiment 2

[0042] An environmentally friendly and toughened nano-cellulose-polylactic acid biodegradable material and its preparation method, the nano-cellulose-polylactic acid biodegradable material includes the following components in weight percentage: polylactic acid 70%, cellulose nano-whiskers 20% , modifier (the mass ratio of triacetin and polyvinyl alcohol is 5:1, the concentration of polyvinyl alcohol aqueous solution is 10%) 8%, and the balance is additives (Y-aminopropyltriethylsilane: talc powder: polyethylene wax=0.5:0.2:0.3); in this embodiment, the preparation method of cellulose nano whiskers refers to patent CN105648816A.

[0043] Concrete preparation steps are as follows:

[0044] 1) Prepare 50ml of 20% cellulose nanowhisker colloidal solution by centrifuging 250ml of 4% cellulose nano whisker aqueous solution (10g of cellulose nano whisker) at 4000rpm for 5min;

[0045] 2) Put 50ml of cellulose nano whisker colloidal solution in step 1) into a glass container, pour 20...

Embodiment 3

[0053] An environmentally friendly and toughened nanocellulose-polylactic acid biodegradable material and its preparation method, the nanocellulose-polylactic acid biodegradable material includes the following components in weight percentage: polylactic acid 72%, cellulose nanofibrils 10% , toughening agent triacetin and polyvinyl alcohol 10%, wherein the ratio of triacetin and polyvinyl alcohol is 3:1, and other processing aids are 1%. The preparation method comprises the following steps:

[0054] 1) Prepare 500ml of 2% cellulose nanofibril solution (10g of cellulose nanofibril) by centrifugation at 3000rpm for 10min to prepare 66.7ml of 15% cellulose nanofibril colloid. Refer to the preparation method of cellulose nanofibril Patent CN101691698A.

[0055] 2) Put 66.7ml of cellulose nanofibril colloid with a concentration of 15% in step 1) in a glass container, pour 200ml of acetone solvent and deionized water mixed solvent, the volume ratio of acetone solvent and deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com