Super-amphiphobic textile finishing agent as well as preparation method and application thereof

A technology for textile finishing and solvent, applied in textile and papermaking, fiber treatment, fiber repelling to liquid, etc., can solve the problems of poor mechanical stability, damage, influence, etc., and achieve the effect of long service life and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of silica sol: under the condition of constant stirring, add ammonia water to 50 parts of methanol solution, adjust the pH to 8.5, then add 2 parts of methyltrimethoxysilane to the mixed solution, and react at a speed of 800rpm 4h to form a transparent silica sol;

[0031] (2) Low surface energy modification: Add 0.3 parts of perfluorodecyltriethoxysilane, 3 parts of fluorocarbon resin and 0.3 parts of hexamethylene diisocyanate curing agent to 50 parts of tetrahydrofuran solution at a rotational speed of 1200 rpm;

[0032] (3) Soak the polyester fabric in (1) for 15 minutes, take it out and dry it at room temperature for 15 minutes, then soak it in (2) for 15 minutes, and finally dry it at 120°C for 2 hours.

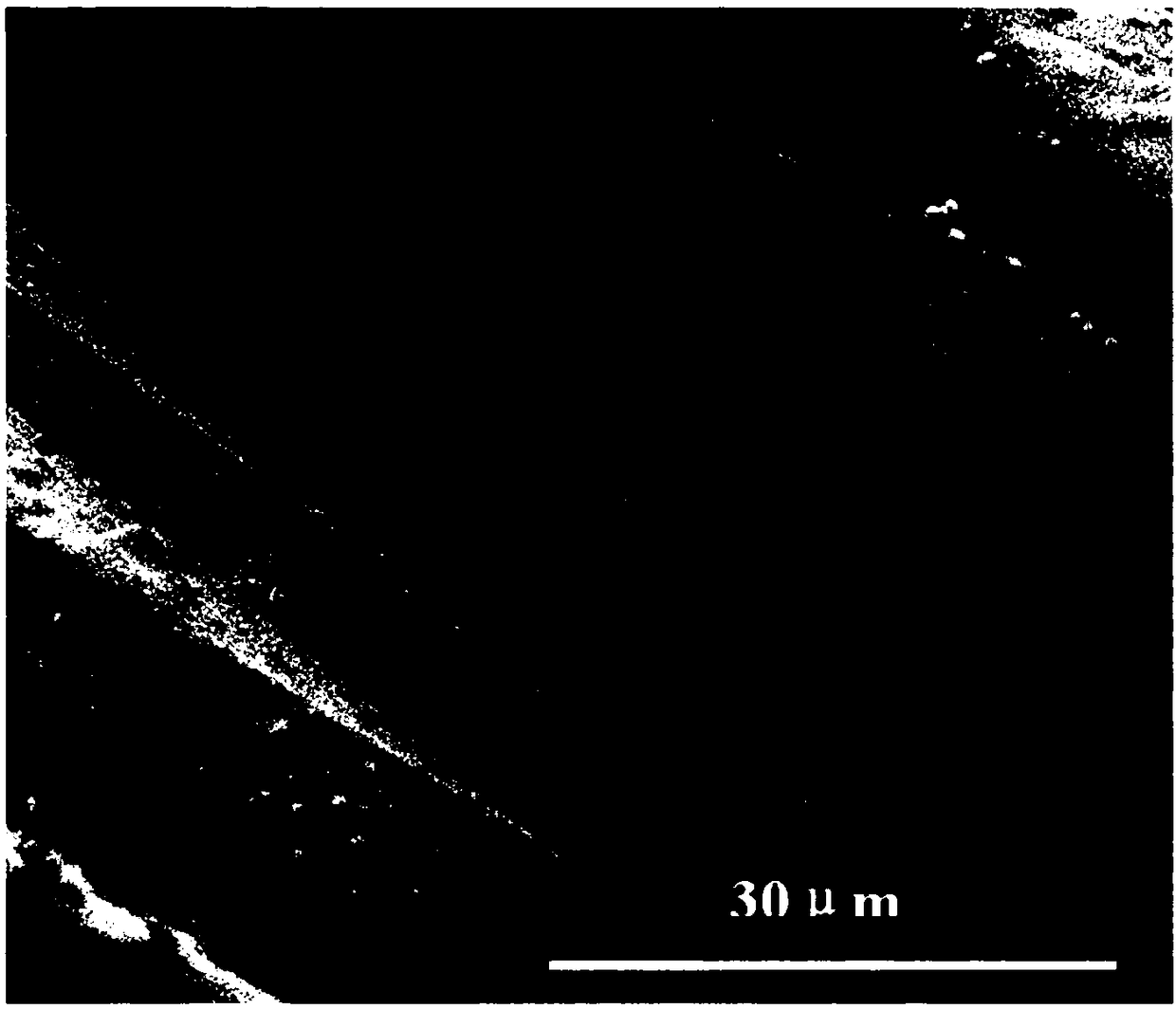

[0033] figure 1 It is a low-magnification scanning electron microscope picture of the superamphiphobic polyester fabric in the embodiment. The prepared super-amphiphobic polyester fabric still maintains super-amphiphobic properties after soaking...

Embodiment 2

[0035] (1) Preparation of silica sol: under the condition of constant stirring, add ammonia water to 50 parts of ethanol solution, adjust the pH to 8.0, then add 2 parts of vinyltriethoxysilane to the mixed solution, and with the speed of 800rpm Reaction 8h forms transparent silica sol;

[0036] (2) Low surface energy modification: Add 0.2 parts of perfluorodecyltrichlorosilane, 2 parts of fluorocarbon resin and 0.1 part of hexamethylene to 50 parts of N,N-dimethylformamide solution at 1000 rpm Diisocyanate curing agent;

[0037] (3) Soak the polyester fabric in (1) for 15 minutes, take it out and dry it at room temperature for 15 minutes, then soak it in (2) for 15 minutes, and finally dry it at 120°C for 2 hours.

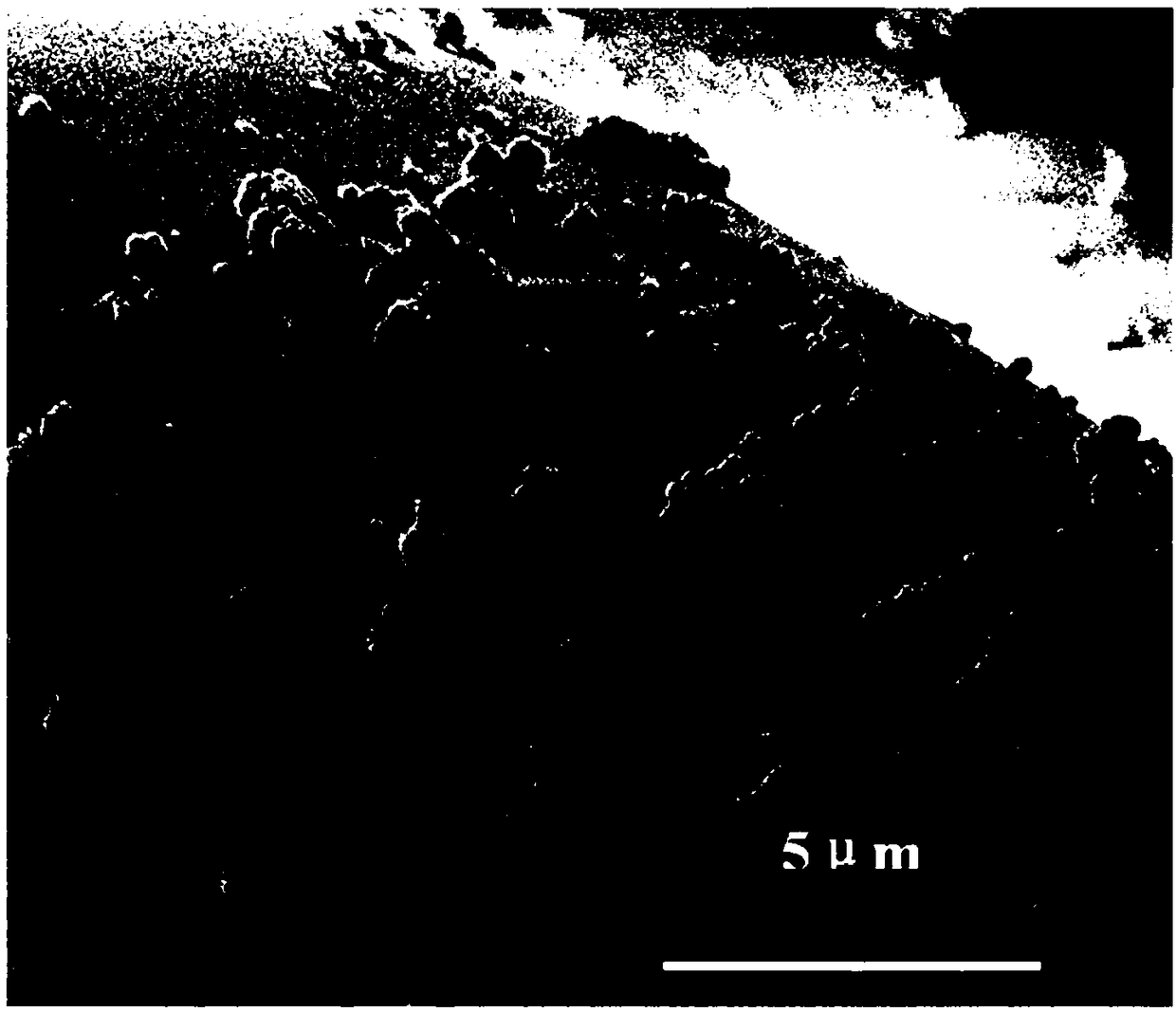

[0038] figure 2 It is a high-magnification scanning electron microscope picture of the superamphiphobic polyester fabric in the embodiment. The prepared superamphiphobic polyester fabric has a water contact angle of more than 150° and an oil droplet contact an...

Embodiment 3

[0040] (1) Preparation of silica sol: under the condition of constant stirring, add ammonia water to 50 parts of isopropanol solution, adjust the pH to 8.5, then add 1 part of trimethylchlorosilane and 2 parts of propyltrimethylsilane to the mixed solution Oxysilane, and reacted for 8 hours at a speed of 800rpm to form a transparent silica sol;

[0041] (2) Low surface energy modification: Add 0.2 parts of perfluorooctyl trichlorosilane and 3 parts of silicone resin, 0.3 parts of vinyltrimethoxy base silane curing agent;

[0042] (3) Soak the pure cotton fabric in (1) for 15 minutes, take it out and dry it at room temperature for 15 minutes, then soak it in (2) for 15 minutes, and finally dry it at 90°C for 2 hours.

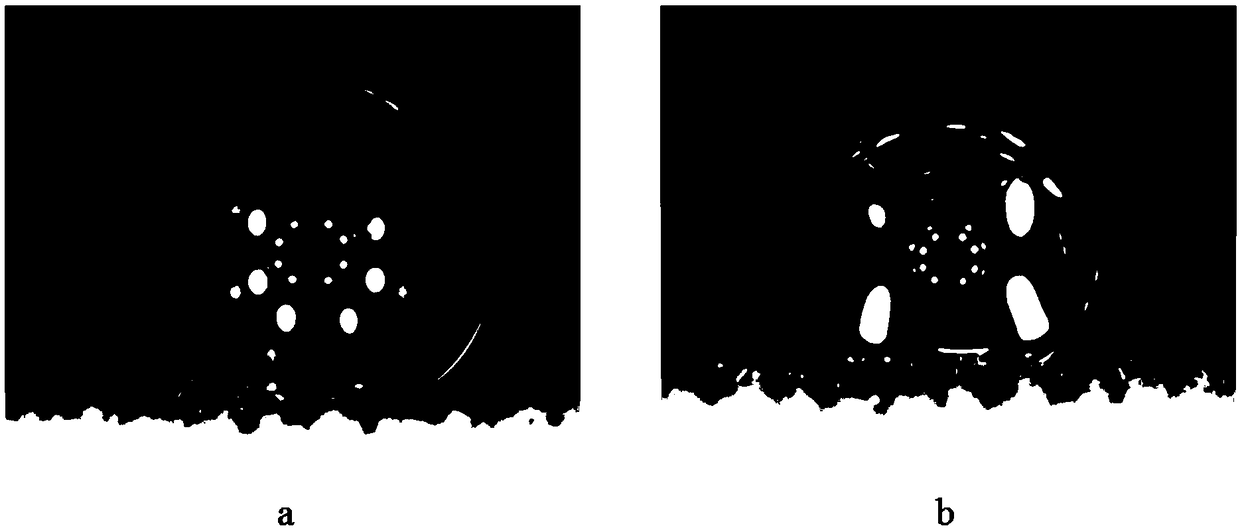

[0043] image 3 Be the water drop ( image 3 a) and oil droplet ( image 3 b) Optical photograph of the contact angle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com