High Performance Polyurethane Adhesives

A polyurethane adhesive, high-performance technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of poor peel strength, low glue concentration, high environmental protection pressure, etc., and achieve energy saving and emission reduction Good performance, low curing temperature, and the effect of reducing corporate taxes and fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

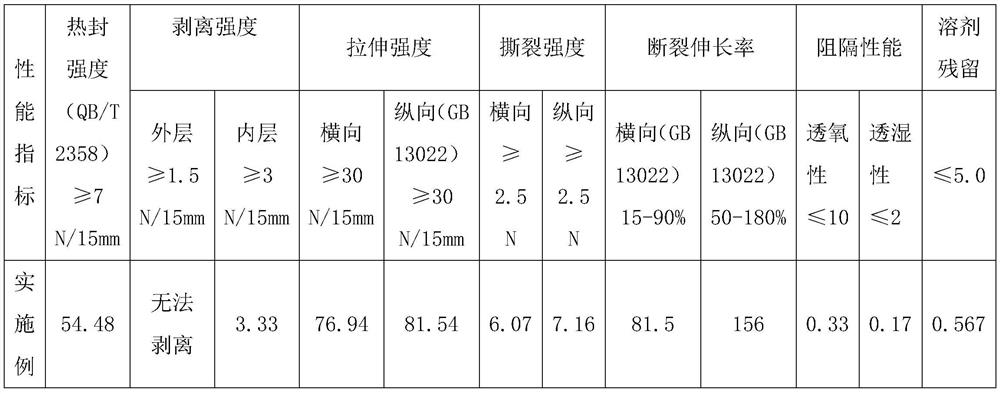

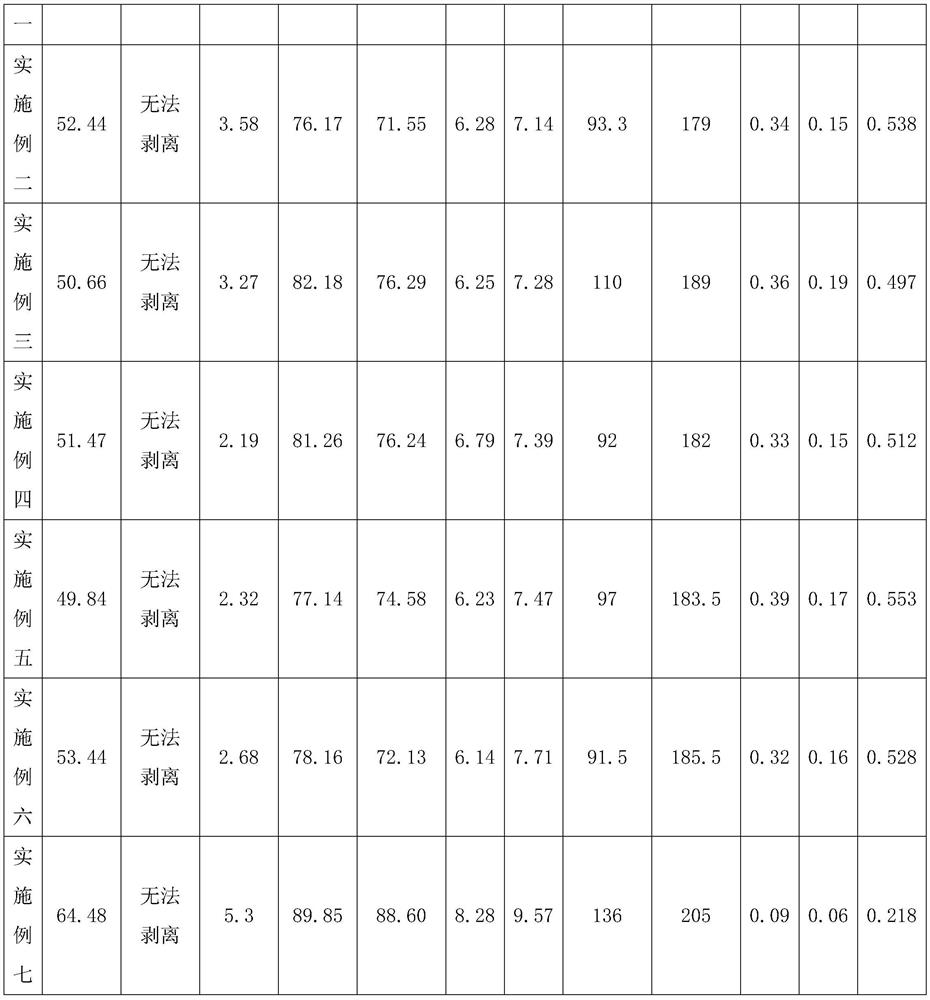

Examples

Embodiment 1

[0047] High-performance polyurethane adhesive, including A component and B component, after A component and B component are uniformly mixed in a mass ratio of 5:1, the high-performance polyurethane adhesive is obtained;

[0048] In parts by weight, component A and component B include the following raw materials:

[0049] A component:

[0050]12 parts of ethylene glycol, 18 parts of 1-4 butanediol, 32 parts of diethylene glycol, 31 parts of neopentyl glycol, 42 parts of isophthalic acid, 0.005 parts of catalyst A, 60 parts of dibasic acid, 44 parts of adipic acid 0.01 part of triphenyl phosphite, 5 parts of castor oil polyol HF-1300 produced by Ito, Japan, 60 parts of ethyl acetate, 10 parts of chain extender, 1.8 parts of carbodiimide, 1.8 parts of silicone coupling agent ;

[0051] B component:

[0052] 48 parts of trimethylolpropane, 14 parts of trimethylpentanediol, 230 parts of chain extender, 95 parts of ethyl acetate, 0.003 parts of catalyst B, and 10 parts of hexamet...

Embodiment 2

[0072] High-performance polyurethane adhesive, including A component and B component, after A component and B component are uniformly mixed in a mass ratio of 5:1, the high-performance polyurethane adhesive is obtained;

[0073] In parts by weight, component A and component B include the following raw materials:

[0074] A component:

[0075] 19 parts of ethylene glycol, 25 parts of 1-4 butanediol, 40 parts of diethylene glycol, 41 parts of neopentyl glycol, 48 parts of isophthalic acid, 0.01 parts of catalyst A, 80 parts of dibasic acid, 59 parts of adipic acid 0.02 parts of triphenyl phosphite, 10 parts of castor oil polyol HF-1300 produced by Ito, Japan, 70 parts of ethyl acetate, 15 parts of chain extender, 2.7 parts of carbodiimide, 2.7 parts of silicone coupling agent ;

[0076] B component:

[0077] 52 parts of trimethylolpropane, 18 parts of trimethylpentanediol, 230 parts of chain extender, 105 parts of ethyl acetate, 0.005 parts of catalyst B, and 15 parts of hexa...

Embodiment 3

[0097] High-performance polyurethane adhesive, including A component and B component, after A component and B component are uniformly mixed in a mass ratio of 5:1, the high-performance polyurethane adhesive is obtained;

[0098] In parts by weight, component A and component B include the following raw materials:

[0099] A component:

[0100] 15 parts of ethylene glycol, 22 parts of 1-4 butanediol, 37 parts of diethylene glycol, 36 parts of neopentyl glycol, 44 parts of isophthalic acid, 0.007 parts of catalyst A, 70 parts of dibasic acid, 51 parts of adipic acid 0.015 parts of triphenyl phosphite, 7 parts of castor oil polyol HF-1300 produced by Ito, Japan, 65 parts of ethyl acetate, 13 parts of chain extender, 2.3 parts of carbodiimide, 2.3 parts of silicone coupling agent ;

[0101] B component:

[0102] 50 parts of trimethylolpropane, 16 parts of trimethylpentanediol, 230 parts of chain extender, 100 parts of ethyl acetate, 0.004 parts of catalyst B, and 13 parts of hexam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com