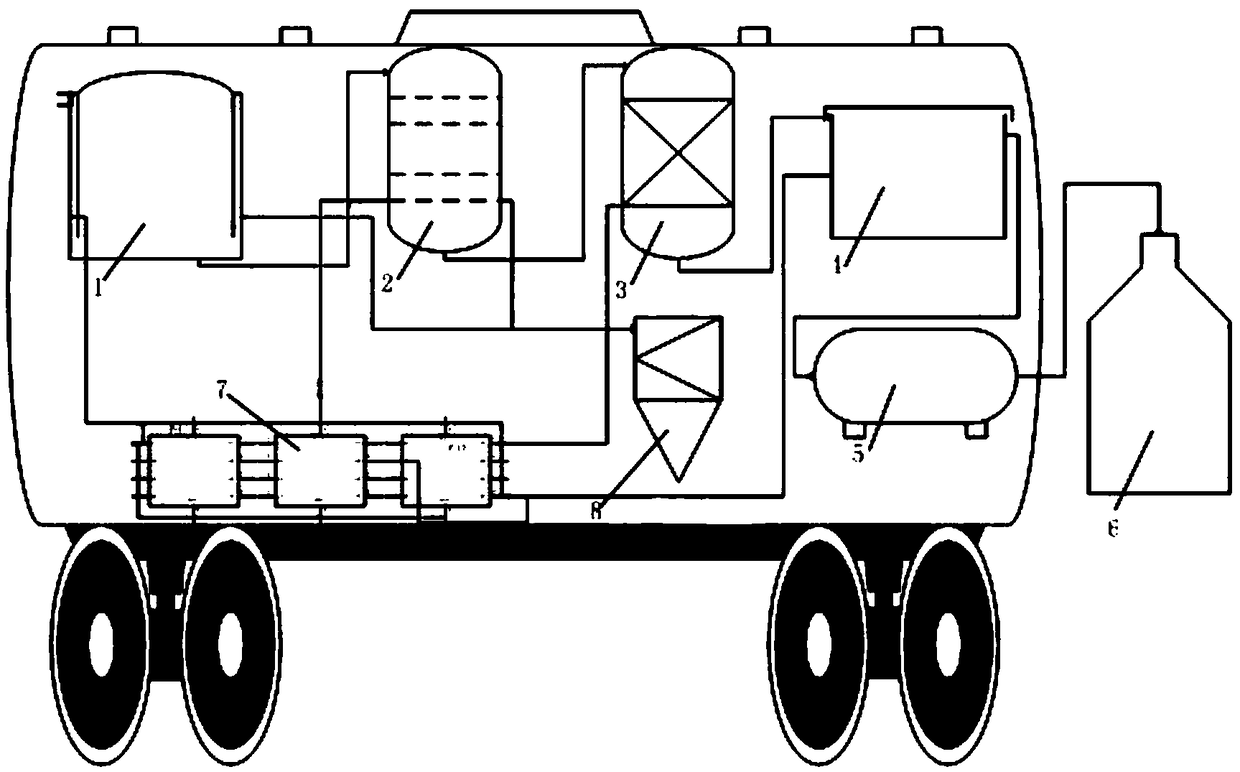

Intelligent vehicle-mounted in-situ treatment and reinjection control system for oil field produced liquids

A control system and in-situ treatment technology, applied in the field of water treatment, can solve the problems of ineffective treatment of dispersed oil wells, poor mobility, high chemical oxygen demand, etc., to reduce fresh water consumption, reduce transportation costs, Combination of reasonable and effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

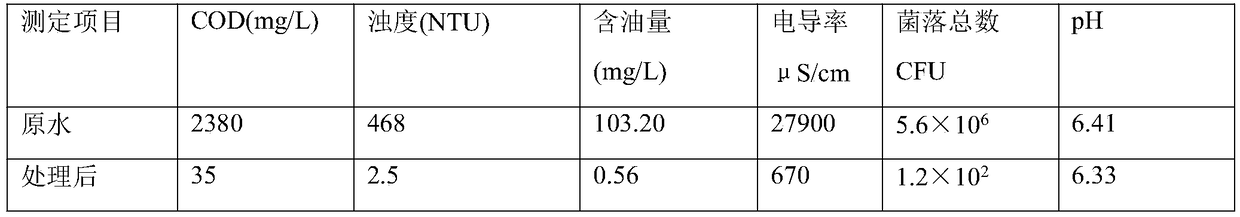

[0036] Embodiment 1: to the processing of certain oilfield production fluid

[0037] The produced fluid from an oilfield first enters the vortex-concave air flotation and oil separation unit, and the aeration rate (air-water ratio 15:1) and demulsification flocculant (30-80mg / L) are adjusted through the intelligent control unit to remove dispersed oil and most Emulsified oil, when the effluent effect is the best, the residence time is 15-20min. The effluent enters the oil removal packing bed equipped with oil removal packing (specially made), this part removes part of the emulsified oil and most of the soluble mineral oil, and the residence time is 3-5min. The effluent enters the ion exchange resin to remove most of the inorganic minerals, etc., and the residence time is 20-30min. Then the effluent enters the inorganic polyphosphate corrosion and scale inhibition adjustment unit, and the effluent after corrosion and scale inhibition enters the ultraviolet lamp sterilization u...

Embodiment 2

[0040] Embodiment 2: to the processing of certain heavy oil crude oil production fluid

[0041] The produced fluid of a heavy oil field first enters the dissolved air flotation and oil separation unit, and adjusts the aeration volume (air-water ratio 10:1-16:1) and PAMAM4.0 (produced by the applicant, patented, 10 -30mg / L), remove the dispersed oil and most of the emulsified oil, when the water effluent effect is the best, the residence time is 5-8min. The effluent enters the oil removal packing bed equipped with oil removal fiber packing (self-made). This part removes part of the emulsified oil and most of the soluble mineral oil, and the residence time is 3-5min. The effluent enters diffusion dialysis to remove most of the inorganic minerals, etc., and the residence time is 10-20min. Then the effluent enters the corrosion and scale inhibition adjustment unit mainly composed of organic phosphonate, and the effluent after corrosion and scale inhibition enters the ultraviolet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com