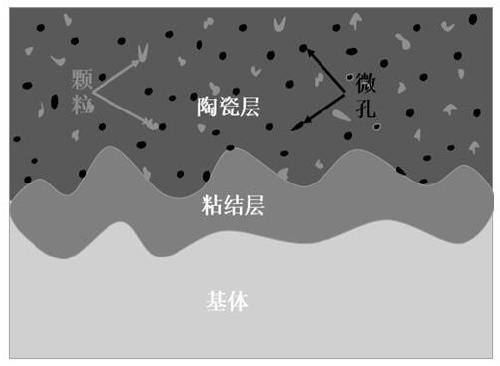

Preparation method of porous wear-resistant thermal spraying ceramic coating

A ceramic coating and thermal spraying technology, applied in the field of wear-resistant coating, can solve the problem of workpiece wear resistance and the surface lubrication of workpiece cannot meet working conditions, etc., to increase comprehensive mechanical properties, prolong lubrication time, and enhance lubrication and wear resistance. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

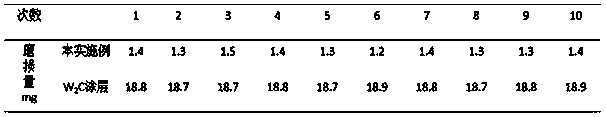

Embodiment 1

[0019] Embodiment 1: a kind of preparation method of porous wear-resistant thermal spray ceramic coating, concrete steps are as follows:

[0020] (1) Grinding, cleaning (ultrasonic cleaning), and sandblasting the metal substrate (45# steel) to make the surface roughness of the metal substrate reach Ra>16;

[0021] (2) Prepare the bonding layer Ni-Co-Cr-Al-Y alloy powder, in terms of mass fraction, wherein the bonding layer Ni-Co-Cr-Al-Y alloy powder contains Co 0.01%, Cr 0.01%, Y 0.01%, Al 7%, the rest is Ni; use plasma spraying method to spray the bonding layer Ni-Co-Cr-Al-Y alloy to the bonding layer Ni-Co-Cr-Al on the metal substrate treated in step (1) The thickness of the -Y alloy layer is 70 μm to obtain the metal base / bonding layer Ni-Co-Cr-Al-Y alloy; wherein the spraying current of the plasma spraying method is 500A, N 2 The rate is 2100mL / h, the spraying distance is 70mm, the powder feeding voltage is 8V, and the preheating temperature of the metal substrate to be s...

Embodiment 2

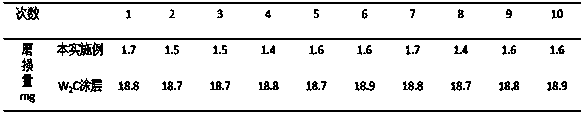

[0029] Embodiment 2: a kind of preparation method of porous wear-resistant thermal spray ceramic coating, concrete steps are as follows:

[0030] (1) The metal substrate (cobalt-based alloy K640) is pre-treated by grinding, cleaning (ultrasonic cleaning), and sandblasting to make the surface roughness of the metal substrate reach Ra>16;

[0031] (2) Prepare the Ni-Co-Cr-Al-Y alloy powder for the bonding layer, in terms of mass fraction, wherein the Ni-Co-Cr-Al-Y alloy powder for the bonding layer contains 10% Co, 24% Cr, Y 2%, Al 12%, and the rest is Ni; use plasma spraying method to spray the bonding layer Ni-Co-Cr-Al-Y alloy to the bonding layer Ni-Co-Cr-Al on the metal substrate treated in step (1) The thickness of the -Y alloy layer is 100 μm to obtain the metal base / bonding layer Ni-Co-Cr-Al-Y alloy; wherein the spraying current of the plasma spraying method is 550A, N 2The rate is 2400mL / h, the spraying distance is 100mm, the powder feeding voltage is 10V, and the prehe...

Embodiment 3

[0039] Embodiment 3: a kind of preparation method of porous wear-resistant thermal spray ceramic coating, concrete steps are as follows:

[0040] (1) The metal substrate (nickel-based alloy In800) is pre-treated by grinding, cleaning (ultrasonic cleaning), and sandblasting to make the surface roughness of the metal substrate reach Ra>16;

[0041] (2) Prepare the bonding layer Ni-Co-Cr-Al-Y alloy powder, in terms of mass fraction, wherein the bonding layer Ni-Co-Cr-Al-Y alloy powder contains Co 5%, Cr 12%, Y 1%, Al 10%, the rest is Ni; use plasma spraying method to spray the bonding layer Ni-Co-Cr-Al-Y alloy to the bonding layer Ni-Co-Cr-Al on the metal substrate treated in step (1) The thickness of the -Y alloy layer is 85 μm to obtain the metal base / bonding layer Ni-Co-Cr-Al-Y alloy; wherein the spraying current of the plasma spraying method is 520A, N 2 The rate is 2250mL / h, the spraying distance is 85mm, the powder feeding voltage is 9V, and the preheating temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com