Coating and preparation method thereof as well as modified asphalt waterproof roll

A technology of coating and petroleum asphalt, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems that the environmental protection treatment device cannot realize the treatment of waste gas, the production line cannot be completely sealed, and the solvent recovery efficiency cannot be guaranteed, so as to improve uniformity Stability, improvement of aging performance, effect of reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In the embodiment of the present invention, the preparation method of coating material comprises:

[0059] 1) Inject high-grade straight-run petroleum asphalt and low-grade petroleum asphalt into the reactor, heat up to 120-140°C, add graphene, and turn on the high-speed disperser to stir for 10-30min;

[0060] 2) Add polymer rubber, keep or raise the temperature to 130-140°C, turn on the colloid mill after 10 minutes, and circulate and stir for 60 minutes;

[0061] 3) Keep at 130-140°C, turn off the colloid mill, add rubber powder and tackifying resin, turn on the colloid mill after 10 minutes, continue to stir for 60 minutes, and conduct an inspection in the central control;

[0062] 4) Add fillers and stir for 20-40 minutes to obtain the coating material.

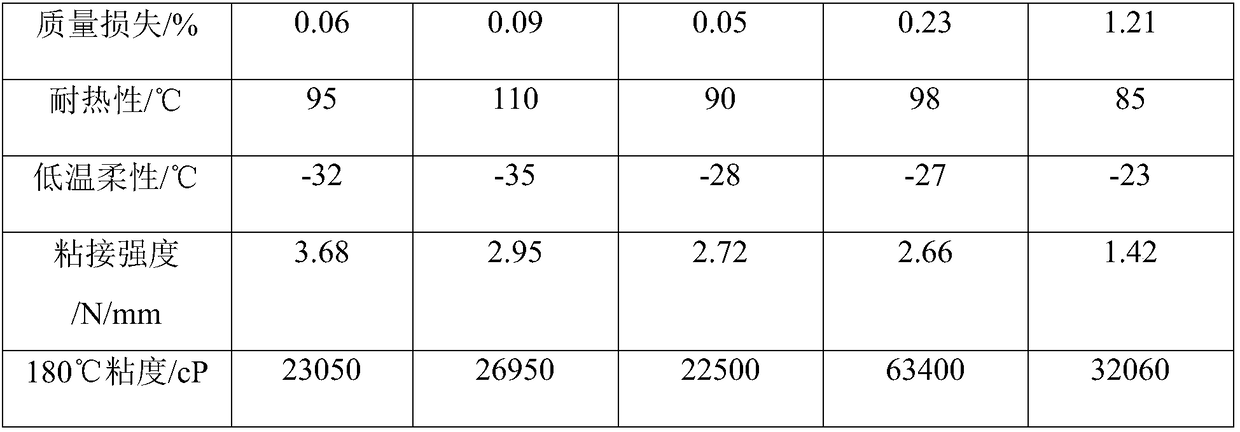

Embodiment 1

[0064] This embodiment provides a coating material.

[0065] Ratio of coating materials: 120 parts of high-grade straight-run petroleum asphalt, 20 parts of No. 70 base petroleum asphalt, 120 parts of polymer rubber, 120 parts of rubber powder rubber, 5 parts of C5 petroleum resin, 0.002 parts of graphene, 19.998 parts of filler. According to the above preparation method, the production temperature is controlled at 135°C. The mass loss is determined to be 0.06% by the differential method before and after preparation. The coating material is prepared into a modified bitumen waterproof membrane, and its key physical properties are tested. The results are shown in Table 1.

Embodiment 2

[0067] This embodiment provides a coating material.

[0068] Ratio of coating materials: 25 parts of high-grade straight-run petroleum asphalt, 15 parts of No. 70 base petroleum asphalt, 323 parts of polymer rubber, 17 parts of rubber powder rubber, 5 parts of C9 petroleum resin, 0.002 parts of graphene, 14.998 parts of filler, according to the above preparation method, the production temperature is controlled at 125 ° C, the mass loss is measured by the differential method before and after preparation to be 0.09%, the coating material is prepared into a modified bitumen waterproof membrane, and its key physical properties are tested. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com