A kind of aluminum alloy diffusion welding method

A technology of diffusion welding and aluminum alloy, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large deformation, lower elastic modulus, and low melting point of aluminum alloy, and achieve good compatibility and improve compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

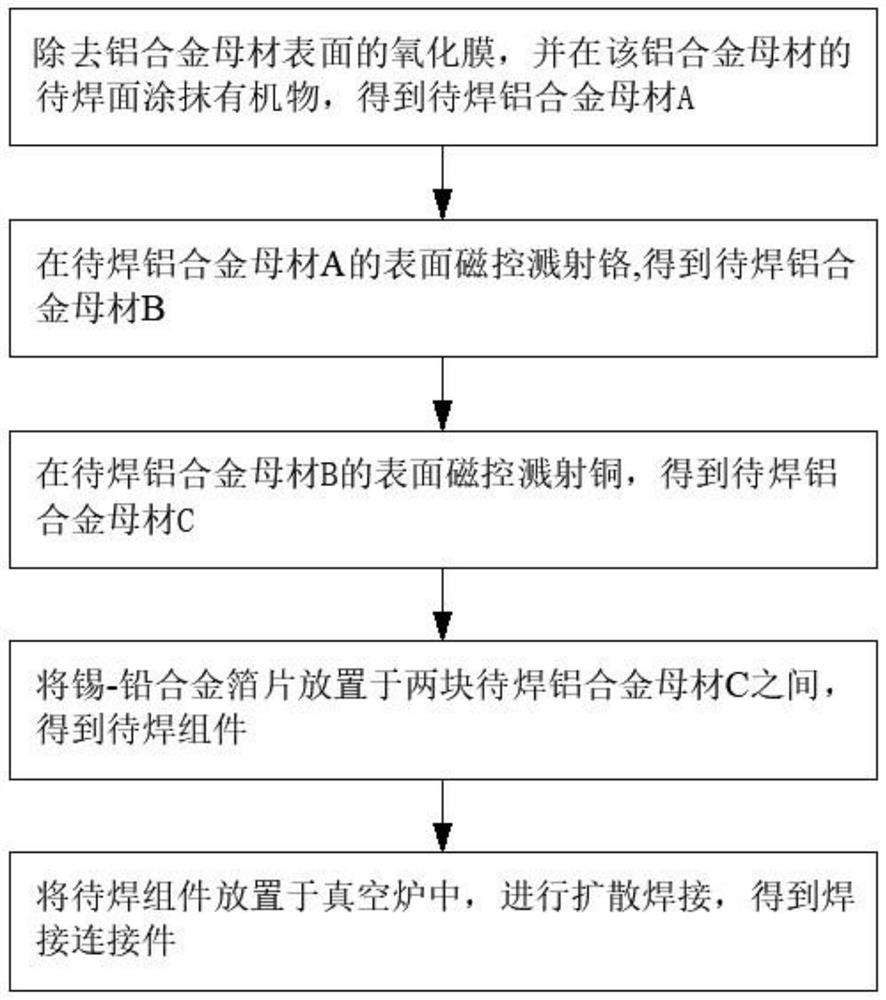

Method used

Image

Examples

Embodiment 1

[0060]The aluminum alloy diffusion welding method provided in this embodiment includes the following steps:

[0061]S1: Clean the surface of the aluminum alloy base material with acetone, remove oil;

[0062]S2: Wipe the surface of the aluminum alloy base material for the oil to remove the oil in the concentration of 5 wt.%, The wipe is 10 minutes;

[0063]S3: After the surface of the sodium hydroxide solution is wiped, the surface of the aluminum alloy base material is cleaned with anhydrous ethanol, and the excess base liquid is removed;

[0064]S4: Wipe the surface of the aluminum alloy base material after the concentration of 12 vol.%, The wipe time is 3 minutes, neutralized residual base, remove the reaction product and carry out light treatment;

[0065]S5: The surface of the aluminum alloy base material after water treatment is cleaned by anhydrous ethanol;

[0066]S6: The surface of the aluminum alloy base material to remove the except for the extent is blown away, and the peppercohol is appl...

Embodiment 2

[0074]The aluminum alloy diffusion welding method provided in this embodiment includes the following steps:

[0075]S1: Clean the surface of the aluminum alloy base material with acetone, remove oil;

[0076]S2: Wipe the surface of the aluminum alloy base material having a concentration of 6 wt.%, The wipe is 10 minutes;

[0077]S3: After the surface of the sodium hydroxide solution is wiped, the surface of the aluminum alloy base material is cleaned with anhydrous ethanol, and the excess base liquid is removed;

[0078]S4: Wipe the surface of the aluminum alloy base material after the concentration of 15 vol.%, The wipe is 3 minutes, the neutralization of the residual base, and the reaction product is removed and the light is removed;

[0079]S5: The surface of the aluminum alloy base material after water treatment is cleaned by anhydrous ethanol;

[0080]S6: The surface of the aluminum alloy base material to remove the except for the extent is blown away, and the peppercohol is applied to weld the ...

Embodiment 3

[0088]The aluminum alloy diffusion welding method provided in this embodiment includes the following steps:

[0089]S1: Clean the surface of the aluminum alloy base material with acetone, remove oil;

[0090]S2: Wipe the surface of the aluminum alloy base material having a concentration of 10 wt.%, The wipe is 10 minutes;

[0091]S3: After the surface of the sodium hydroxide solution is wiped, the surface of the aluminum alloy base material is cleaned with anhydrous ethanol, and the excess base liquid is removed;

[0092]S4: Wipe the surface of the aluminum alloy base material after the concentration of 20 vol.%, The wipe is 3 minutes, the neutralization time is 3 minutes, neutralized residual base, remove the reaction product and perform light treatment;

[0093]S5: The surface of the aluminum alloy base material after water treatment is cleaned by anhydrous ethanol;

[0094]S6: The surface of the aluminum alloy base material to remove the except for the extent is blown away, and the peppercohol is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com