A kind of aluminum alloy diffusion welding device and aluminum alloy diffusion welding method

A technology of diffusion welding and aluminum alloy, which is applied in the direction of welding/welding/cutting items, welding equipment, non-electric welding equipment, etc. It can solve problems such as hole defects, electrochemical corrosion, and the service life of aluminum alloy materials that affect the strength of joints, etc., to increase Large pressure, the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In order to solve the current problem that large-sized aluminum alloy materials cannot be diffusion-welded, this embodiment provides an aluminum alloy diffusion welding device, through which the aluminum alloy diffusion device can realize diffusion welding of large-sized aluminum alloy materials.

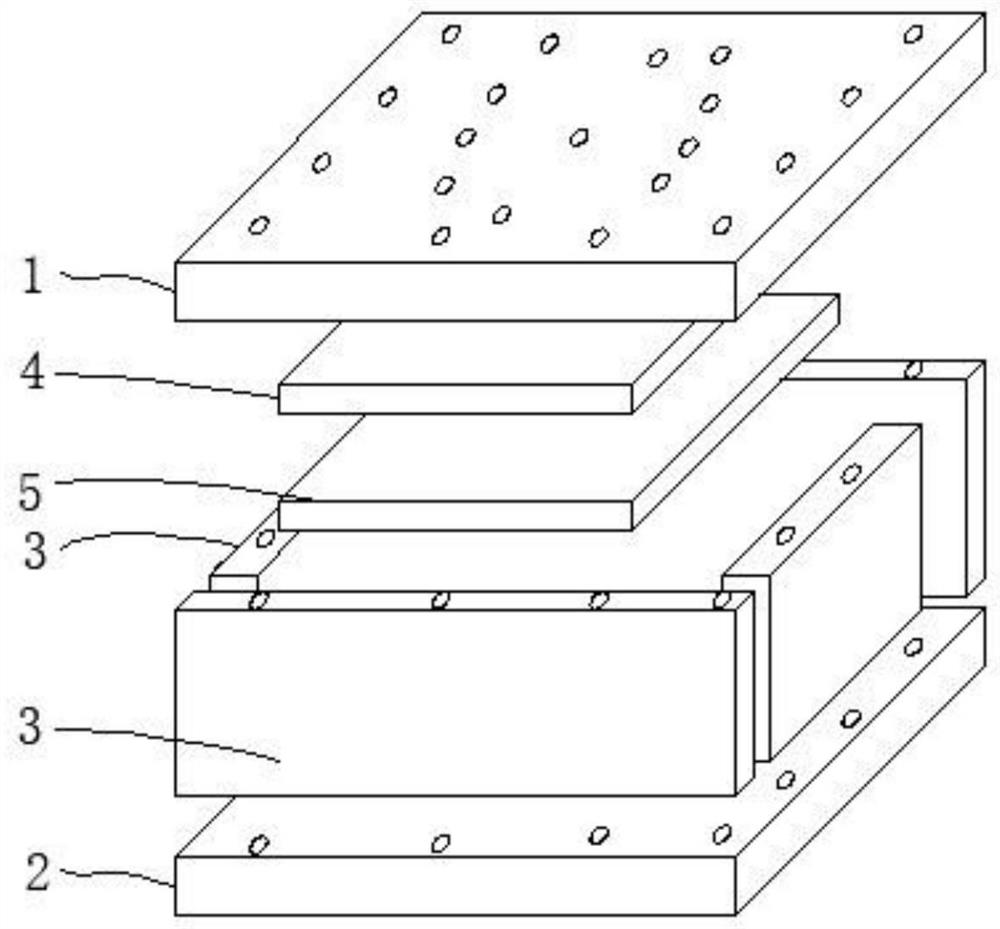

[0039] This embodiment provides an aluminum alloy diffusion welding device, which includes a fixture, see figure 1 As shown, the jig includes an upper plate 1, a lower plate 2 and at least two side plates 3; wherein the upper plate 1, the lower plate 2, and the side plates 3 are all plate-shaped structures with a certain thickness, and the upper plate 1 and the lower plate 2. The size of the side plate 3 is determined according to the size of the workpiece 5 to be welded; the linear expansion coefficient of the fixture is smaller than that of the aluminum alloy.

[0040] When using the aluminum alloy diffusion welding device, the lower plate 2 is connected to the lower end of...

Embodiment 2

[0053] On the basis of embodiment 1, see figure 1 As shown, in the aluminum alloy diffusion welding device provided in this embodiment, the jig further includes a pressure plate 4 , and when using the aluminum alloy diffusion welding device, the pressure plate 4 is placed between the workpiece 5 to be welded and the upper plate 1 .

[0054] In order to ensure the additional pressure due to the coefficient of linear expansion when the weldment 5 is to be diffused welded, it is necessary to select a material with a coefficient of linear expansion not less than that of the side plate 3 as the pressure plate 4; if the coefficient of linear expansion of the pressure plate 4 is smaller than that of the side plate, During diffusion welding, the expansion degree of the side plate 3 will be greater than that of the pressure plate 4, resulting in an increase in the distance between the upper plate 1 and the lower plate 2, reducing the additional pressure exerted by the upper plate 1 on t...

Embodiment 3

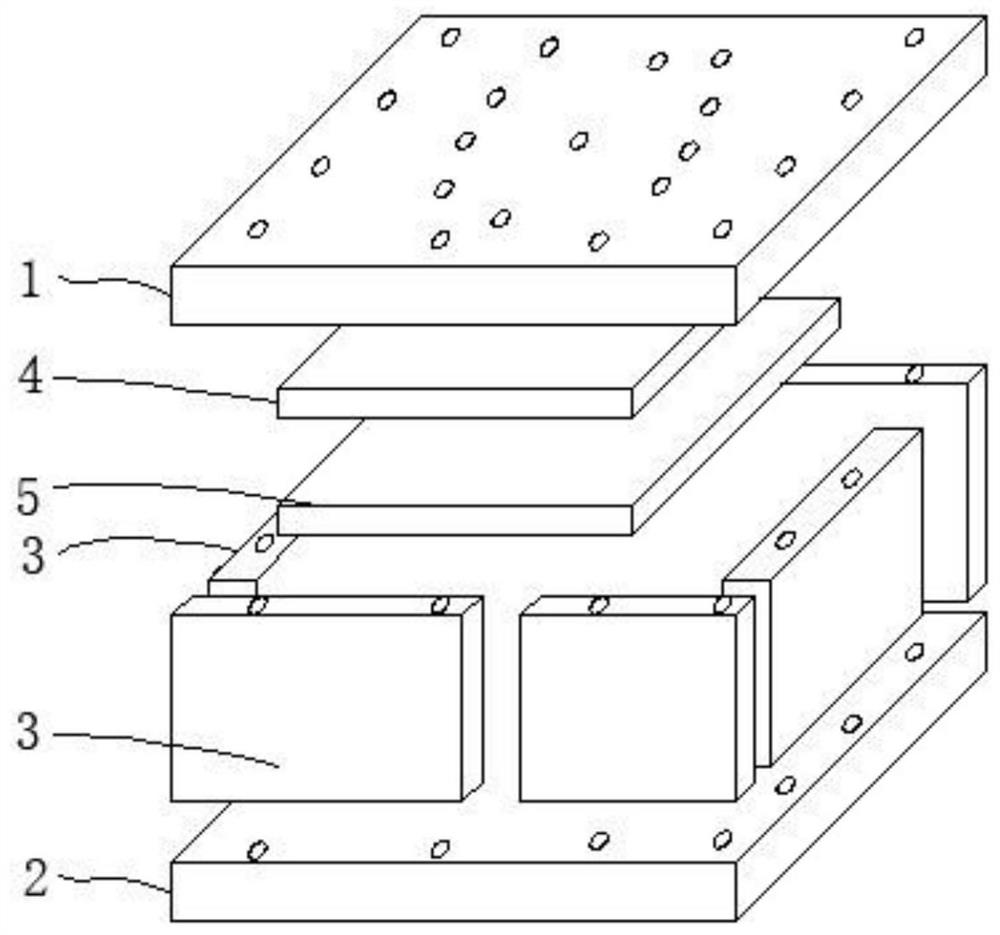

[0057] On the basis of Embodiment 2, the number of side plates 3 in this embodiment is four, and the four side plates 3 are all vertically connected to the bottom plate 2, and the adjacent side plates 3 are perpendicular to each other, but are not connected, that is, they are connected to each other. There are gaps between the adjacent side plates 3; the four side plates 3 and the bottom plate 2 together form a square structure, and the four side plates 3 jointly restrict the plastically deformed parts 5 to be welded during diffusion welding. , Adjusting function, avoiding the severe plastic deformation of the weldment 5 during diffusion welding, which will cause the failure of diffusion welding, and reduce the deformation of aluminum alloy when using this fixture for diffusion welding.

[0058] see figure 2 As shown, because the side plate 3 will also expand to a certain extent during the diffusion welding process, in order to avoid deformation caused by the expansion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com