Large-deformation enhanced rapid ion nitriding method

A technology of ion nitriding and large deformation, applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of core strength decrease, surface layer relaxation, surface layer peeling, etc., and achieve strength and hardness The effect of improving, improving chemical activity, and overcoming the decrease in core hardness and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

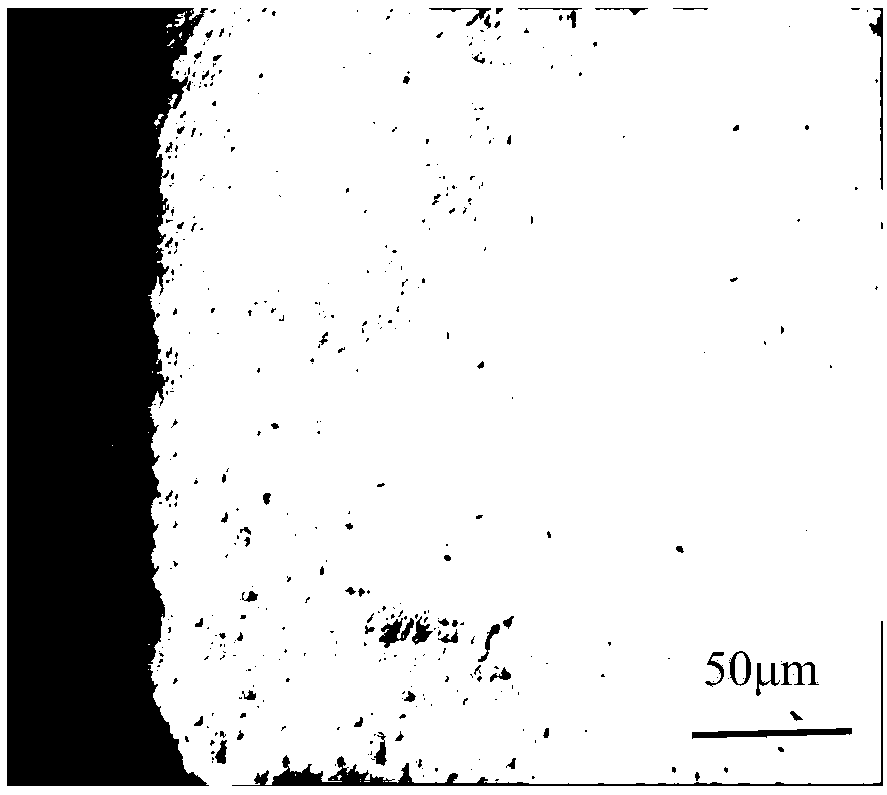

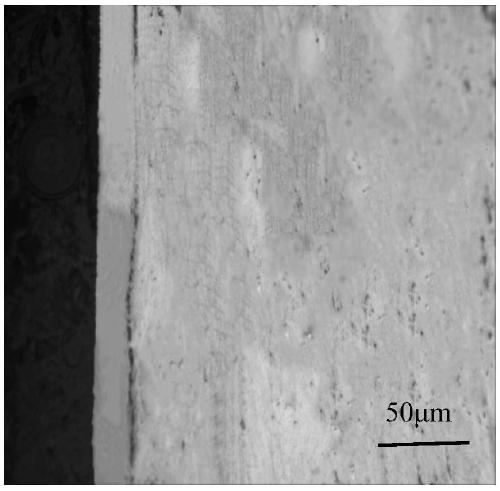

Image

Examples

Embodiment 1

[0031] (1) Processing the original state steel into a plate shape;

[0032] (2) Perform solid solution treatment on the plate-shaped steel to be nitrided, raise the temperature to 1050°C and keep it warm for 60 minutes, and then immediately put the sample into water to cool to room temperature;

[0033] (3) Place the solid solution state steel to be nitrided on the four-roll experimental rolling mill, and carry out cold rolling treatment with a deformation of 30%, resulting in large plastic deformation;

[0034] (4) The steel to be nitrided after large plastic deformation is processed by wire cutting into a sample size of 10mm×10mm×5mm. Ultrasonic cleaning in organic solvents and drying after grinding;

[0035] (5) Place the sample in the ion nitriding furnace, evacuate to below 10Pa, pass in hydrogen gas for sputtering for 30min, and keep the pressure in the furnace at 300Pa. Then nitrogen gas was introduced, the flow rates of nitrogen gas and hydrogen gas were 200ml / min an...

Embodiment 2

[0039] (1) Processing the original state steel into a plate shape;

[0040] (2) Perform solid solution treatment on the plate-shaped steel to be nitrided, raise the temperature to 1050°C and keep it warm for 60 minutes, and then immediately put the sample into water to cool to room temperature;

[0041] (3) Place the solid solution state steel to be nitrided on the four-roll experimental rolling mill, and carry out cold rolling treatment with a deformation of 50%, resulting in large plastic deformation;

[0042] (4) The steel to be nitrided after large plastic deformation is processed by wire cutting into a sample size of 10mm×10mm×5mm. Ultrasonic cleaning in organic solvents and drying after grinding;

[0043] (5) Place the sample in the ion nitriding furnace, evacuate to below 10Pa, pass in hydrogen gas for sputtering for 30min, and keep the pressure in the furnace at 300Pa. Then nitrogen gas was introduced, the flow rates of nitrogen gas and hydrogen gas were 200ml / min an...

Embodiment 3

[0047] (1) Processing the original state steel into a plate shape;

[0048] (2) Perform solid solution treatment on the plate-shaped steel to be nitrided, raise the temperature to 1050°C and keep it warm for 60 minutes, and then immediately put the sample into water to cool to room temperature;

[0049] (3) Place the solid solution state steel to be nitrided on the four-roll experimental rolling mill, and carry out cold rolling treatment with a deformation of 70%, resulting in large plastic deformation;

[0050] (4) The steel to be nitrided after large plastic deformation is processed by wire cutting into a sample size of 10mm×10mm×5mm. Ultrasonic cleaning in organic solvents and drying after grinding;

[0051](5) Place the sample in the ion nitriding furnace, evacuate to below 10Pa, pass in hydrogen gas for sputtering for 30min, and keep the pressure in the furnace at 300Pa. Then nitrogen gas was introduced, the flow rates of nitrogen gas and hydrogen gas were 200ml / min and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com