Anticorrosive power transmission tower outer coating

A power tower, anti-corrosion technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of not improving the thermal conductivity of coatings, poor heat dissipation performance of coatings, etc., achieve good gloss and color retention, increase The effect of long service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

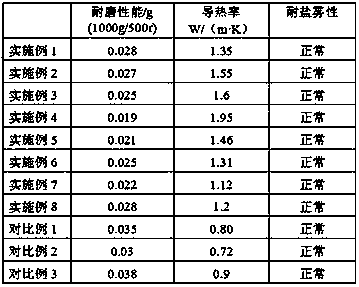

Examples

Embodiment 1

[0023] An anti-corrosion power pole and tower outer layer coating, made of the following raw materials in parts by weight: 30 parts of hydroxyacrylic resin, 15 parts of polyurethane emulsion, 12 parts of thermal conductive filler, 1 part of calcium sulfate whisker, 3 parts of molybdenum powder, and asbestos powder 0.5 parts, UV absorber 0.1 parts, sodium methyl silicate 0.5 parts, polyvinyl alcohol 1 part, polydimethylsiloxane 1 part, glyceryl monostearate 1 part, organic solvent 15 parts.

[0024] The organic solvent is formed by mixing xylene and butyl acetate at a weight ratio of 1:1.

[0025] The thermally conductive filler is prepared by the following steps: after uniformly mixing titanium dioxide, nano-alumina, and silicon nitride whiskers, stirring evenly with an ethanol solution with twice the weight and mass fraction of 5% stearic acid, at 90-100°C Calcined to obtain thermally conductive fillers.

[0026] Wherein the ultraviolet absorber is 2-(2-hydroxyl-5-methylphen...

Embodiment 2

[0032] An anti-corrosion power pole and tower outer layer coating, made of the following raw materials in parts by weight: 32 parts of hydroxyl acrylic resin, 16 parts of polyurethane emulsion, 11 parts of thermal conductive filler, 1.5 parts of calcium sulfate whiskers, 2.5 parts of molybdenum powder, and asbestos powder 0.8 parts, UV absorber 0.12 parts, sodium methyl silicate 0.4 parts, polyvinyl alcohol 1.5 parts, polydimethylsiloxane 1.5 parts, glyceryl monostearate 1.5 parts, organic solvent 16 parts.

[0033] The organic solvent is formed by mixing xylene and butyl acetate at a weight ratio of 1.5:1.

[0034] The thermally conductive filler is prepared by the following steps: after uniformly mixing titanium dioxide, nano-alumina, and silicon nitride whiskers, stirring evenly with an ethanol solution with twice the weight and mass fraction of 6% stearic acid, at 90-100°C Calcined to obtain thermally conductive fillers.

[0035] Wherein the ultraviolet absorber is resorc...

Embodiment 3

[0041] An anti-corrosion power pole and tower outer layer coating, made of the following raw materials in parts by weight: 34 parts of hydroxyacrylic resin, 18 parts of polyurethane emulsion, 10 parts of thermal conductive filler, 2 parts of calcium sulfate whiskers, 2 parts of molybdenum powder, and asbestos powder 1 part, 0.14 parts of UV absorber, 0.3 parts of sodium methyl silicate, 1.5 parts of polyvinyl alcohol, 1.8 parts of polydimethylsiloxane, 2 parts of glyceryl monostearate, 18 parts of organic solvent.

[0042] The organic solvent is formed by mixing xylene and butyl acetate at a weight ratio of 2:1.

[0043] The thermally conductive filler is prepared by the following steps: after uniformly mixing titanium dioxide, nano-alumina, and silicon nitride whiskers, stirring evenly with 2.5 times the ethanol solution with a mass fraction of 7% stearic acid, at 90-100°C Calcined to obtain thermally conductive fillers.

[0044] Wherein the ultraviolet absorber is 2-(2-hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com