Preparation method of green chelating agent tetrasodium glutamate diacetate

A technology of tetrasodium glutamic acid diacetate and sodium glutamate is applied in the preparation of organic compounds, cyanide reaction preparation, chemical instruments and methods, etc. Complicated and other problems, to achieve stable product quality, avoid the use of highly toxic substances, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

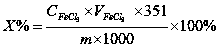

Image

Examples

Embodiment 1

[0026] (1) Add 567g of sodium glutamate monohydrate, 262g of sodium hydroxide aqueous solution (32% by mass) and 253g of deionized water into the reaction kettle, stir and mix evenly, and the neutralization degree of sodium glutamate is about 70%;

[0027] (2) Dissolve 601g of chloroacetic acid in 520g of deionized water and put it into a constant pressure dropping funnel for later use;

[0028] (3) 1038g mass percentage composition is 50% sodium hydroxide aqueous solution and is put into another constant pressure dropping funnel for subsequent use;

[0029] (4) Raise the temperature of the reactor system to 80°C, add the aqueous solution of chloroacetic acid in step (2) and the liquid caustic soda in step (3) dropwise, and control the rate of addition so that the temperature of the reaction system is at 82±2°C and the pH The value is kept in the range of 10.0~10.5, and the dropwise addition is completed in 3.5 hours; while the dropwise addition reaction is started, under the...

Embodiment 2

[0033] (1) Add 567g of sodium glutamate, 200g of sodium hydroxide aqueous solution (30% by mass) and 188g of deionized water into the reaction kettle, stir and mix evenly, and the neutralization degree of sodium glutamate is about 50 %;

[0034] (2) Dissolve 630g of chloroacetic acid in 386g of deionized water and put it into a constant pressure dropping funnel for later use;

[0035] (3) 1306g mass percentage composition is 45% sodium hydroxide aqueous solution and is put into another constant pressure dropping funnel for subsequent use;

[0036] (4) Raise the temperature of the reactor system to 82°C, and add dropwise the aqueous solution of chloroacetic acid in step (2) and the liquid caustic soda in step (3), and control the rate of addition so that the temperature of the reaction system is at 85±2°C and the pH The value is kept in the range of 10.5~11.0, and the dropwise addition is completed in 4 hours; at the same time as the dropwise addition reaction is started, unde...

Embodiment 3

[0040] (1) Add 378g of sodium glutamate, 150g of sodium hydroxide aqueous solution (32% by mass) and 151g of deionized water into the reaction kettle, stir and mix evenly, and the neutralization degree of sodium glutamate is about 60 %;

[0041] (2) Dissolve 439g of chloroacetic acid in 310g of deionized water and put it into a constant pressure dropping funnel for later use;

[0042] (3) Put 800g of 47% sodium hydroxide aqueous solution into another constant pressure dropping funnel for subsequent use;

[0043] (4) Raise the temperature of the reactor system to 82°C, and add dropwise the aqueous solution of chloroacetic acid in step (2) and the liquid caustic soda in step (3), and control the rate of addition so that the temperature of the reaction system is at 84±2°C and the pH The value is kept in the range of 9.0~9.5, and the dropwise addition is completed in 5 hours; while the dropwise reaction is started, under the negative pressure condition of -0.002MPa, the water in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com