Preparation method of ammonium paratungstate composite powder comprising rare earth

A technology of ammonium paratungstate and ammonium tungstate, which is applied in the field of cemented carbide material preparation, can solve problems such as uneven distribution of rare earth, and achieve the effects of refining APT particle size, improving dispersibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take the APT workshop of a certain factory to use the soda high pressure leaching method, and then use the ion exchange method to produce 300ml of the second-stage liquid ammonium tungstate solution after impurity removal in a stirring pot, WO 4 2- The concentration is 260g / L, and the temperature should not be higher than 40℃.

[0027] Weigh 0.05 g of yttrium nitrate, add it to a beaker containing 5 ml of deionized water, and stir with a glass rod until the yttrium nitrate is completely dissolved. While stirring the ammonium tungstate solution at a speed of 60 rad / min, slowly add the yttrium nitrate solution to the ammonium tungstate solution, keep stirring for 5 minutes, and keep the temperature not higher than 40°C to obtain the ammonium tungstate / rare earth salt precursor composite solution .

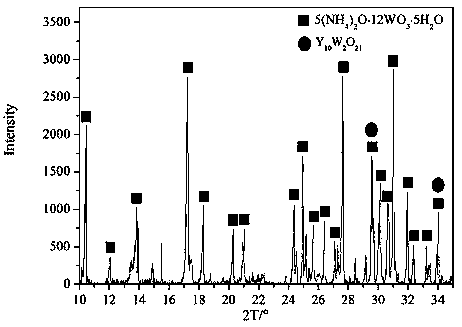

[0028] Transfer the precursor composite solution to a magnetic stirrer and heat to 80°C for evaporation and crystallization. The magnetic stirring rotor rotates at 120 rad / min. Whe...

example 2

[0030] Take the APT workshop of a certain factory to use the soda high pressure leaching method, and then use the ion exchange method to produce 300ml of the second-stage liquid ammonium tungstate solution after impurity removal in a stirring pot, WO 4 2- The concentration is 260g / L, and the temperature should not be higher than 40℃.

[0031] Weigh 2.19 g of yttrium nitrate, add it to a beaker containing 5 ml of deionized water, and stir with a glass rod until the yttrium nitrate is completely dissolved. While stirring the ammonium tungstate solution at a speed of 60 rad / min, slowly add the yttrium nitrate solution to the ammonium tungstate solution, keep stirring for 5 minutes, and keep the temperature not higher than 40°C to obtain the ammonium tungstate / rare earth salt precursor composite solution .

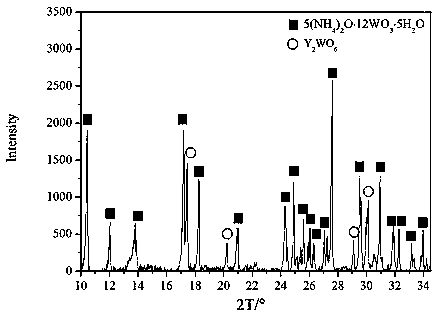

[0032] Transfer the precursor composite solution to a magnetic stirrer and heat to 80°C for evaporation and crystallization. The magnetic stirring rotor rotates at 120 rad / min. Whe...

example 3

[0034] Take the APT workshop of a certain factory to use the soda high pressure leaching method, and then use the ion exchange method to produce 300ml of the second-stage liquid ammonium tungstate solution after impurity removal in a stirring pot, WO 4 2- The concentration is 260g / L, and the temperature should not be higher than 40℃.

[0035] Weigh 5.55 g of yttrium nitrate, add it to a beaker containing 5 ml of deionized water, and stir with a glass rod until the yttrium nitrate is completely dissolved. While stirring the ammonium tungstate solution at a speed of 60 rad / min, slowly add the yttrium nitrate solution to the ammonium tungstate solution, keep stirring for 5 minutes, and keep the temperature not higher than 40°C to obtain the ammonium tungstate / rare earth salt precursor composite solution .

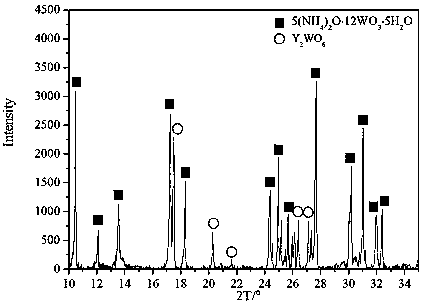

[0036] Transfer the precursor composite solution to a magnetic stirrer and heat to 80°C for evaporation and crystallization. The magnetic stirring rotor rotates at 120 rad / min. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com