A corrosion-resistant carbon fiber artificial water grass brick and its preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing corrosion-resistant carbon fiber artificial water grass bricks, mainly comprising the following steps:

[0030] (1) Cut out 30 sections of polyacrylonitrile-based carbon fiber (carbon fiber strength is 1000MPa, modulus is 100GPa), each section is 12cm long; soak the carbon fiber in 1mol / L sodium hydroxide solution for 24h, and then place it in a container Modified carbon fibers are obtained by electrochemical modification in an electrolytic cell with an electrolyte, wherein the electrolyte is NH 4 HCO 3 and (NH 4 ) 2 C 2 o 4 ·H 2 O is prepared by mixing with a molar ratio of 1:1, the electrolysis time is 30min, and the current intensity is 600mA;

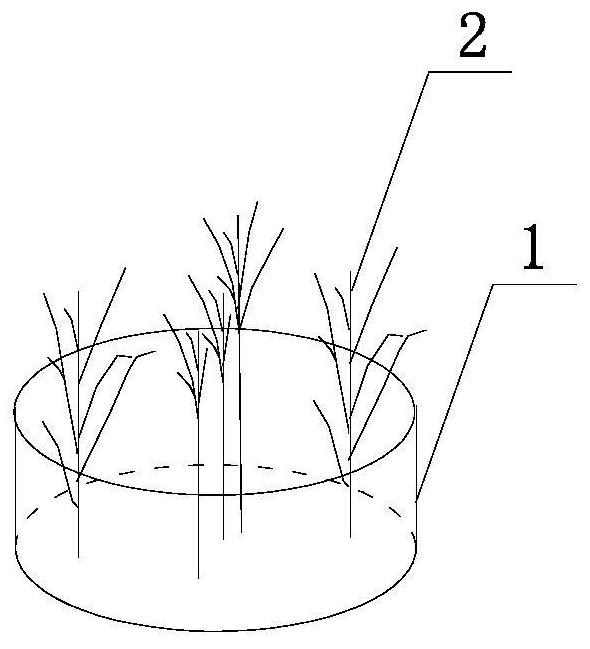

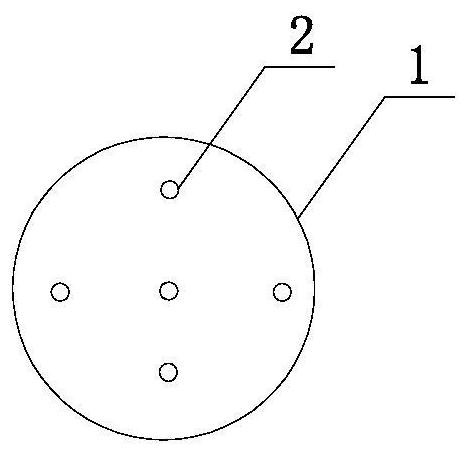

[0031] (2) Weigh furan resin and sulfamic acid with a mass ratio of 1:3, put them into a cylindrical brick mold with a diameter of 6 cm and a height of 2 cm, mix them evenly, and cure them at 20° C. for 2 days to obtain a solidified base; Among them, when the curing time is 12 hours and the fixed...

Embodiment 2

[0038] A method for preparing corrosion-resistant carbon fiber artificial water grass bricks, mainly comprising the following steps:

[0039] (1) Cut out 30 sections of polyacrylonitrile-based carbon fiber (carbon fiber strength is 1800MPa, modulus is 200GPa), each section is 12cm long; soak the carbon fiber in 5mol / L sodium hydroxide solution for 48h, and then place it in a container Modified carbon fibers are obtained by electrochemical modification in an electrolytic cell with an electrolyte, wherein the electrolyte is NH 4 HCO 3 and (NH 4 ) 2 C 2 o 4 ·H 2 O is prepared by mixing the molar ratio of 1:4, the electrolysis time is 120min, and the current intensity is 1800mA;

[0040](2) Weigh furan resin and ethyl sulfate with a mass ratio of 1:10, put them into a cylindrical brick mold with a diameter of 6 cm and a height of 2 cm, mix them evenly, and cure them at 40° C. for 1 day to obtain a solidified base; , when the curing time is 2 hours and the fixed base becomes...

Embodiment 3

[0044] A method for preparing corrosion-resistant carbon fiber artificial water grass bricks, mainly comprising the following steps:

[0045] (1) Cut 30 sections of polyacrylonitrile-based carbon fiber (the strength of carbon fiber is 1500MPa, the modulus is 150GPa), each section is 7cm long; soak the carbon fiber in 3mol / L sodium hydroxide solution for 12h, and then place it in a container Electrochemical modification is carried out in the electrolytic cell with electrolyte to obtain modified carbon fiber, wherein, NH 4 HCO 3 and (NH 4 ) 2 C 2 o 4 ·H 2 O is prepared by mixing the molar ratio of 1:2, the electrolysis time is 10min, and the current intensity is 300mA;

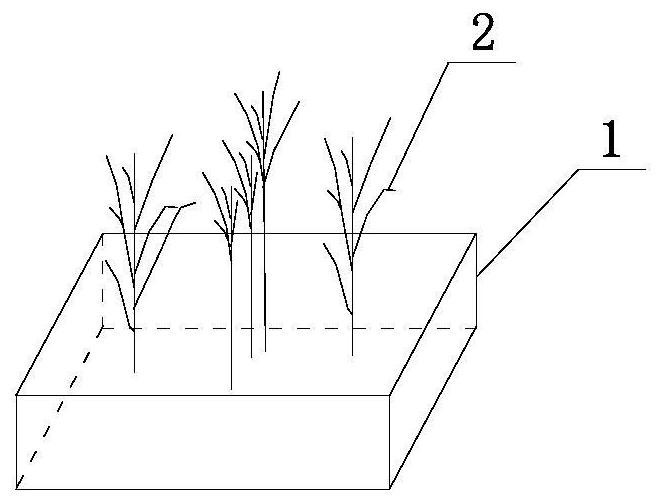

[0046] (2) Weigh furan resin and p-toluenesulfonic acid with a mass ratio of 1:6, put them into a rectangular brick-making mold with a length of 5 cm, a width of 2.5 cm, and a height of 1.2 cm, mix evenly, and maintain at 30 ° C for 1 Obtain the solidified fixed base every day, wherein; When the curing ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com