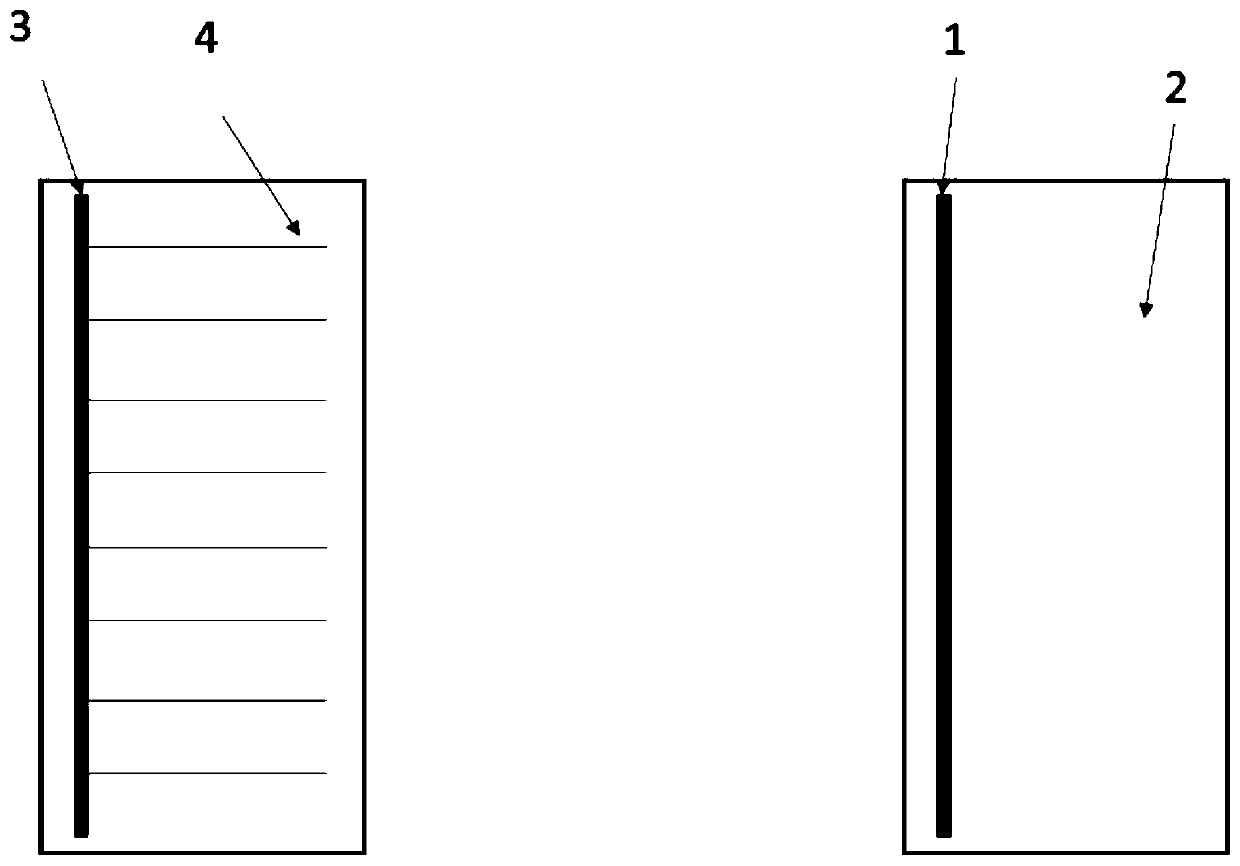

Solar cell string, solar cell module and manufacturing method thereof

A technology for solar cells and cells, which is applied in the field of solar cells, can solve the problems of high cell stacking accuracy and high process difficulty, and achieve the effects of reducing back silver paste waste, increasing passivation area, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0116] According to the preparation method of the present invention, the sintering temperature of the front silver electrode is 750-1000°C; the sintering temperature of the aluminum back field is 450-650°C. Preferably, the sintering temperature of the front silver electrode is 800-950°C; the sintering temperature of the aluminum back field is 550-650°C.

[0117] In a specific embodiment, the sintering temperature of the front silver electrode is 850°C; the sintering temperature of the aluminum back field is 580°C. Of course, the simultaneous sintering of the front silver electrode and the aluminum back field can be realized after drying separately, and one sintering is completed.

[0118] In a specific embodiment, the method for preparing a solar cell string of the present invention, the method includes the following steps:

[0119] Carry out texturing, diffusion, etching and coating treatment on the crystalline silicon substrate in sequence;

[0120] Print aluminum paste on...

Embodiment 1

[0176] In this embodiment, epoxy resin-based conductive adhesive is used. Specifically, the epoxy resin is prepared according to the following method.

[0177] The components used to prepare the conductive adhesive are as follows:

[0178] 6 parts of epoxy resin DER-354 (Dow Chemical), 4 parts of epoxy resin DER-852 (Dow Chemical), 2 parts of curing agent diaminodiphenylsulfone (Nanjing Chemical Reagent Co., Ltd.), 1 part of diluent , 10 parts of 4-butanediol diglycidyl ether (Aladdin reagent), 75 parts of flake silver powder (METALOR), 2 parts of curing accelerator 1,1-dimethyl-3-phenylurea (Aladdin reagent) , 0.5 parts of conduction accelerator succinic acid (Aladdin reagent), 0.5 parts of coupling agent Z6040 (DOWCORNING), the sum of the above components is 100 parts.

[0179] The preparation method of conductive adhesive is as follows:

[0180] First mix the above epoxy resin with the above diluent and coupling agent evenly, then add the above curing agent, the above con...

Embodiment 2

[0188] Prepared according to the same method as Example 1, except that only 5 parts of epoxy resin DER-354 is used, no other epoxy resin is used, and the amount of 1,4-butanediol diglycidyl ether diluent is changed to 5 parts Part, 1 part of diaminodiphenyl sulfone curing agent, 1 part of 1,1-dimethyl-3-phenylurea curing accelerator is changed into 1 part, and flake silver powder is changed into 88 parts, according to the same as embodiment 1 The conductive adhesive was prepared in this way.

[0189] The crystalline silicon substrate was processed in the same manner as in Example 1, and what was used here was an N-type single-sided single-crystal cell (wherein the difference from Example 1 was only in the diffusion process, and powdered boron nitride Diffusion is carried out by pressing the tablet, the diffusion temperature is 950-1000°C, and the diffusion time is 15-30min), except that a rubber strip with a width of 2mm and a length of 120mm is coated on the aluminum back fie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com