High-manganese low-chromium type hot work die steel and preparation method thereof

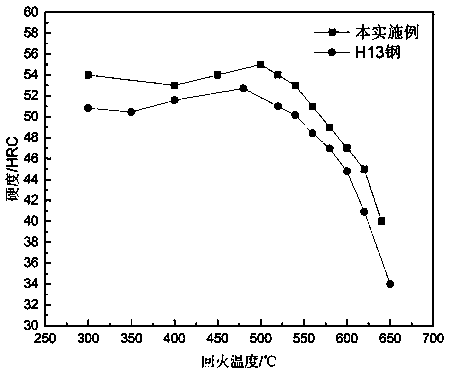

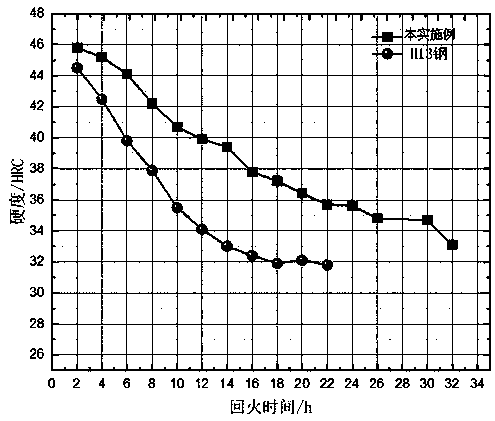

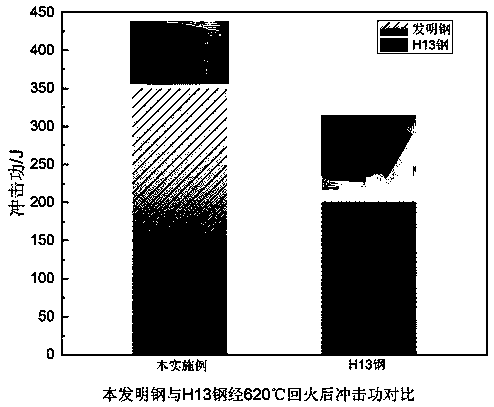

A hot work die steel, high manganese technology, applied in the field of hot work die steel, can solve the problems of drop, poor toughness and plasticity, poor secondary hardening ability during tempering, etc. The effect of improving thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Based on the mass percentage of high manganese and low chromium type hot work die steel in this example, including C 0.35%, Si0.50%, Mn 0.60%, Cr 3.75%, Mo 0.80%, V 0.30%, Co 0.50 %, Ni 0.80%, P 0.006%, S 0.004%, the balance is Fe and unavoidable impurities;

[0029] A preparation method of high manganese and low chromium type hot work die steel, the specific steps are:

[0030] (1) Weigh pig iron, ferrosilicon, ferromanganese, ferrochrome, ferromolybdenum, vanadium-iron-cobalt and nickel according to the chemical composition of high manganese and low chromium hot work die steel;

[0031] (2) Add the materials prepared in step (1) into an induction furnace for induction melting to obtain molten steel, wherein the melting temperature is 1640°C;

[0032] (3) Stir the molten steel smelted in step (2) evenly, then cast to obtain steel ingot I of Φ80mm, then place steel ingot I as a consumable electrode in the electroslag remelting device for electroslag remeltin...

Embodiment 2

[0041] Example 2: Based on the mass percentage of high manganese and low chromium hot work die steel in this example, including C0.40%, Si0.80%, Mn0.80%, Cr4.00%, Mo1.00%, V0. 40%, Co2.50%, Ni1.50%, P0.006%, S0.004%, the balance is Fe and unavoidable impurities;

[0042] A preparation method of high manganese and low chromium type hot work die steel, the specific steps are:

[0043] (1) Weigh pig iron, ferrosilicon, ferromanganese, ferrochrome, ferromolybdenum, vanadium-iron-cobalt and nickel according to the chemical composition of high manganese and low chromium hot work die steel;

[0044] (2) Add the materials prepared in step (1) into an induction furnace for induction melting to obtain molten steel, wherein the melting temperature is 1640°C;

[0045] (3) Stir the molten steel smelted in step (2) evenly, then cast to obtain steel ingot I of Φ80mm, then place steel ingot I as a consumable electrode in the electroslag remelting device for electroslag remelting to obtain re...

Embodiment 3

[0054] Example 3: Based on the mass percentage of high manganese and low chromium hot work die steel in this example, including C0.42%, Si1.00%, Mn1.00%, Cr4.20%, Mo1.10%, V0. 50%, Co4.50%, Ni2.50%, P0.006%, S0.004%, the balance is Fe and unavoidable impurities;

[0055] A preparation method of high manganese and low chromium type hot work die steel, the specific steps are:

[0056] (1) Weigh pig iron, ferrosilicon, ferromanganese, ferrochrome, ferromolybdenum, vanadium-iron-cobalt and nickel according to the chemical composition of high manganese and low chromium hot work die steel;

[0057] (2) Add the materials prepared in step (1) into the electric furnace for electric furnace melting to obtain molten steel, wherein the melting temperature is 1640°C;

[0058] (3) Stir the molten steel smelted in step (2) evenly, then cast to obtain steel ingot I of Φ80mm, then place steel ingot I as a consumable electrode in the electroslag remelting device for electroslag remelting to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com