Preparation method of hydrophobic weather-resistant and aging-resistant composite fluorocarbon resin coating for tent

An aging-resistant and compound fluorine technology, used in anti-corrosion coatings, coatings, etc., can solve problems such as poor weather resistance, general coating performance, insufficient sunlight resistance and high temperature resistance, and achieve good adhesion, reduced photocatalytic activity, and hardness. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

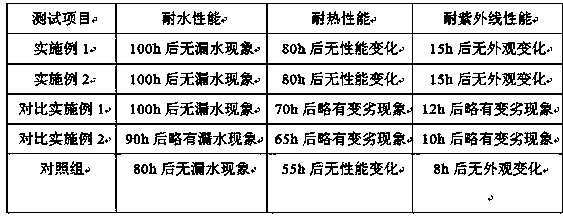

Examples

Embodiment 1

[0023] A method for preparing a hydrophobic weather-resistant and aging-resistant composite fluorocarbon resin coating for a tent, characterized in that it comprises the following steps:

[0024] (1) Cerium oxide CeO 2 Coated titanium dioxide:

[0025] Add 0.02 parts of dispersant sodium hexametaphosphate to the titanium dioxide slurry, ultrasonically disperse for 30 minutes, set the temperature of the constant temperature bath at 65-70°C, add inorganic coating agents cerium nitrate solution and sodium hydroxide solution, and keep the pH value of the slurry at 9 , after aging for 1 h, suction filter and wash 3 times, dry the filter cake in an electric vacuum oven at 104-106 °C for 8 h, and grind to obtain cerium oxide CeO 2 Coated titanium dioxide:

[0026] (2) Preparation of silica nano-fluid:

[0027] Dilute 7 parts of silica sol to 40 parts with deionized water, ultrasonically disperse for 10 minutes, add 10 parts of methanol solution of additives, age for 22 hours, remo...

Embodiment 2

[0037] A method for preparing a hydrophobic weather-resistant and aging-resistant composite fluorocarbon resin coating for a tent, characterized in that it comprises the following steps:

[0038] (1) Cerium oxide CeO 2 Coated titanium dioxide:

[0039] Add 0.03 parts of dispersant sodium hexametaphosphate to the titanium dioxide slurry, ultrasonically disperse for 35 minutes, set the temperature of the constant temperature bath at 65-70°C, add inorganic coating agents cerium nitrate solution and sodium hydroxide solution, and keep the pH value of the slurry at 9 , aged for 2 hours, filtered and washed 5 times, dried the filter cake in an electric vacuum oven at 104-106°C for 10 hours, and ground to obtain cerium oxide CeO 2 Coated titanium dioxide:

[0040] (2) Preparation of silica nano-fluid:

[0041] Dilute 8 parts of silica sol to 46 parts with deionized water, ultrasonically disperse for 15 minutes, add 11 parts of methanol solution of additives, age for 24 hours, remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com