Ultraviolet-resistant cerium oxide coated nano zinc oxide powder and composite paint comprising same

A nano-zinc oxide powder and composite coating technology, applied in the field of coatings, can solve the problems of accelerated degradation of organic coatings, degradation of coating weather resistance, application limitations, etc., and achieve the effects of improved dispersion, easy operation, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (A) Get 0.2mol / L cerium nitrate solution, add 0.05g of anionic surfactant sodium lauryl sulfate and 20g of nanometer zinc oxide powder in every 100ml of cerium nitrate solution, and disperse and dissolve to obtain solution A.

[0048] (B) Take 0.3mol / L sodium bicarbonate solution with the same volume as solution A, slowly drop it into solution A, and react for 1 hour at a temperature of 50°C and a rotation speed of 1200r / min until the reaction is complete and white precipitation.

[0049] (C) The resulting white precipitate was centrifuged and washed 3 times with distilled water.

[0050] (D) Dry the separated white precipitate in a constant temperature drying oven at 50° C. for 12 hours.

[0051] (E) Sintering the dried white powder at 290° C. for 1 hour.

Embodiment 2

[0053] (A) Get 0.3mol / L cerium nitrate solution, add 0.15g of anionic surfactant sodium lauryl sulfate and 60g of nanometer zinc oxide powder in every 100ml of cerium nitrate solution, and disperse and dissolve to obtain solution A.

[0054] (B) Take 0.4mol / L sodium bicarbonate solution of the same volume as solution A, slowly drop it into solution A, and stir for 1 hour at a temperature of 50°C and a rotation speed of 1200r / min until the reaction is complete and a white precipitate is produced .

[0055] (C) The resulting precipitated mixture was centrifuged and washed 3 times with distilled water.

[0056] (D) Put the separated solid into a constant temperature drying oven at 50° C. for 12 hours.

[0057] (E) Sintering the dried white powder at 300° C. for 1 hour.

Embodiment 3

[0059] (A) Get 0.5mol / L cerium nitrate solution, add 0.3g of anionic surfactant sodium lauryl sulfate and 150g nanometer zinc oxide powder in every 100ml of cerium nitrate solution, and disperse and dissolve to obtain solution A.

[0060](B) Take 0.5 mol / L sodium bicarbonate solution of the same volume as solution A, slowly drop it into solution A, and stir for 1 hour at a temperature of 50°C and a rotation speed of 1200r / min until the reaction is complete and a white precipitate is produced .

[0061] (C) The resulting precipitated mixture was centrifuged and washed 3 times with distilled water.

[0062] (D) Put the separated solid into a constant temperature drying oven at 50° C. for 12 hours.

[0063] (E) Sintering the dried white powder at 300° C. for 1 hour.

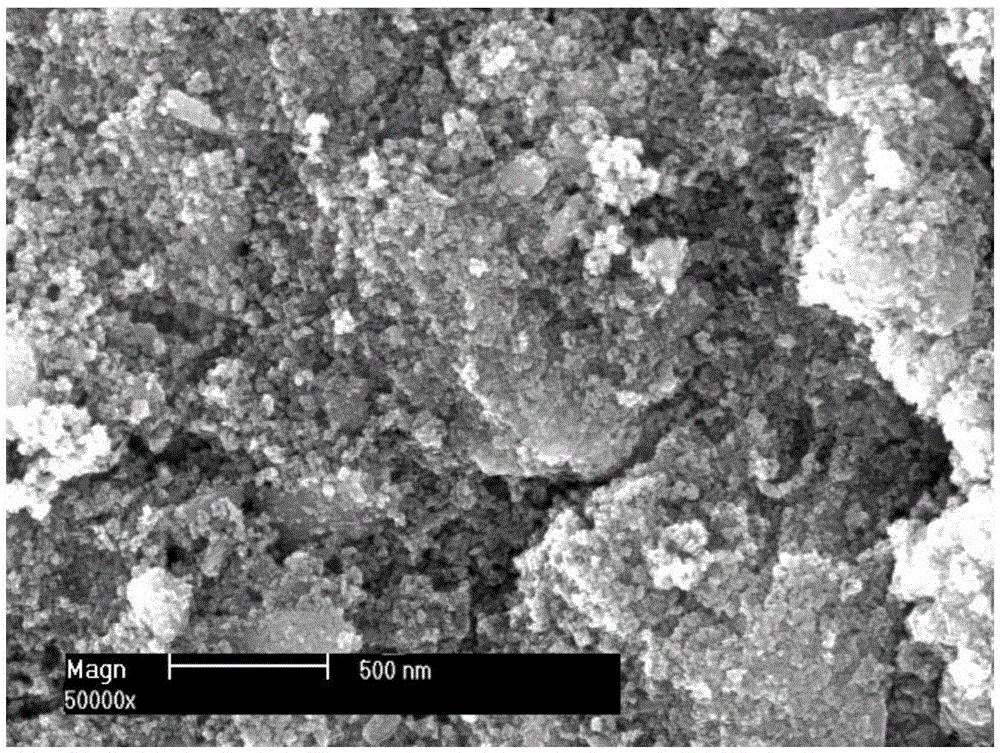

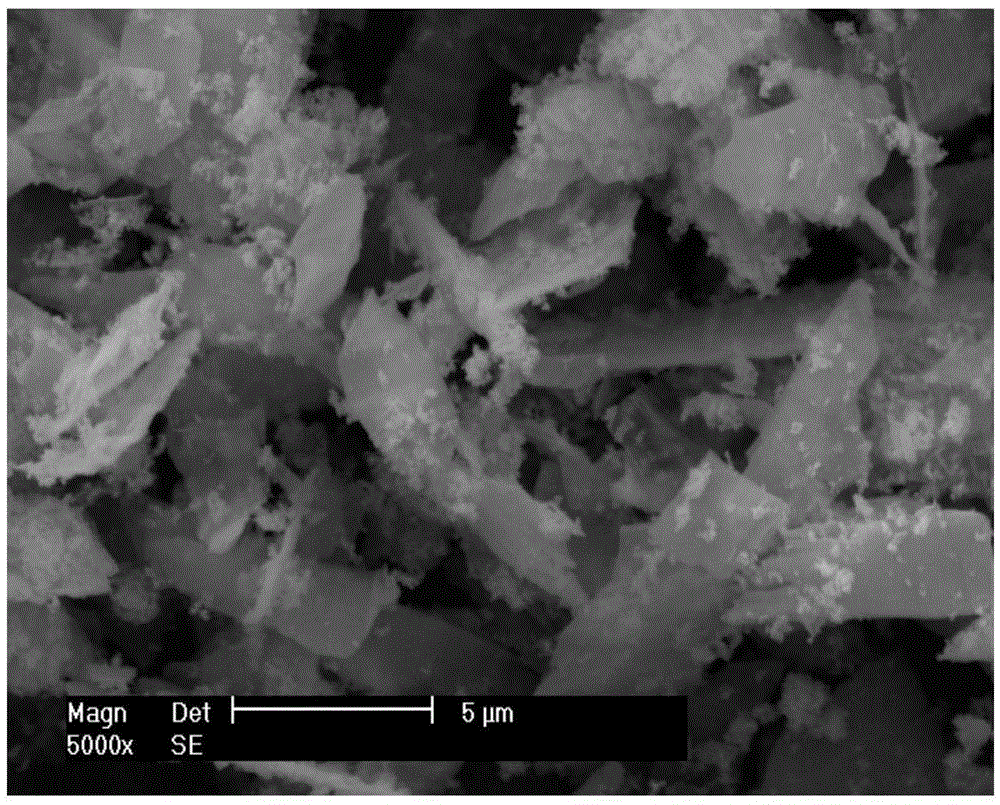

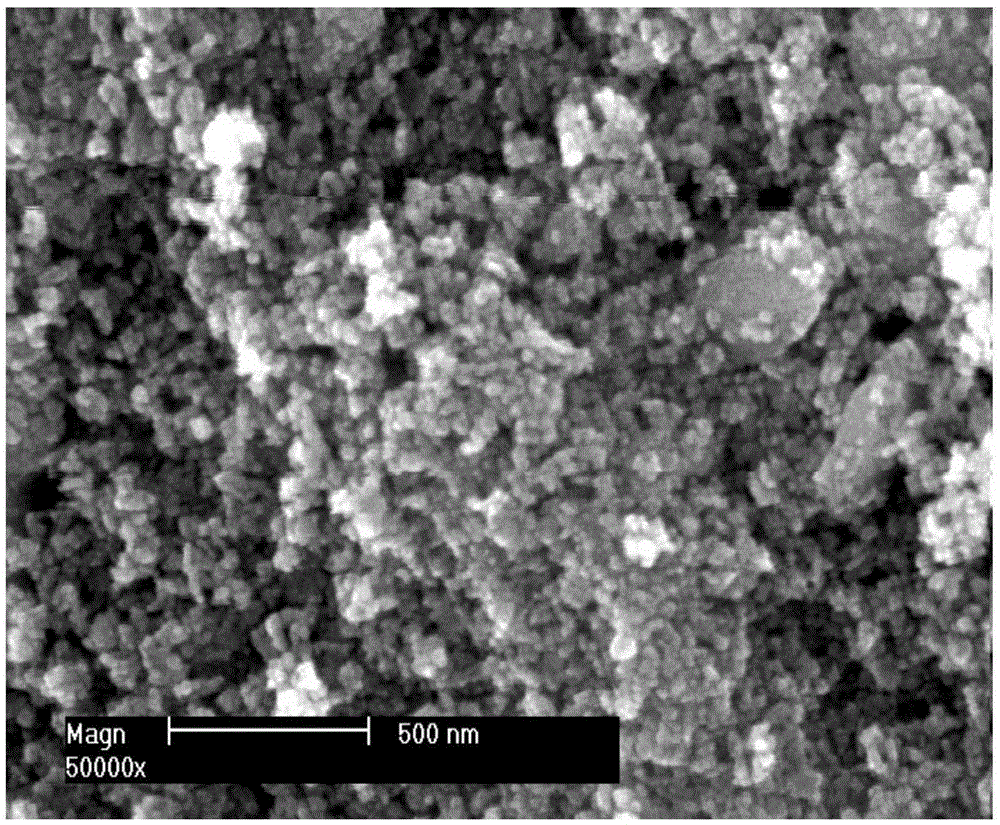

[0064] The micro-morphology of nano zinc oxide powder coated with cerium oxide was observed by ESEM (ESEMXL30FEG) environmental scanning electron microscope.

[0065] From comparative example 1 ( figure 1 ) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com