Separation and recycling method of waste tin-plated copper wire

A technology for separation and recovery and tin-plated copper, which is applied in the field of separation and recovery of waste tin-plated copper rice, can solve the problems of incomplete separation effect, adhesion and high processing cost, and achieves low cost, complete separation and simple processing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

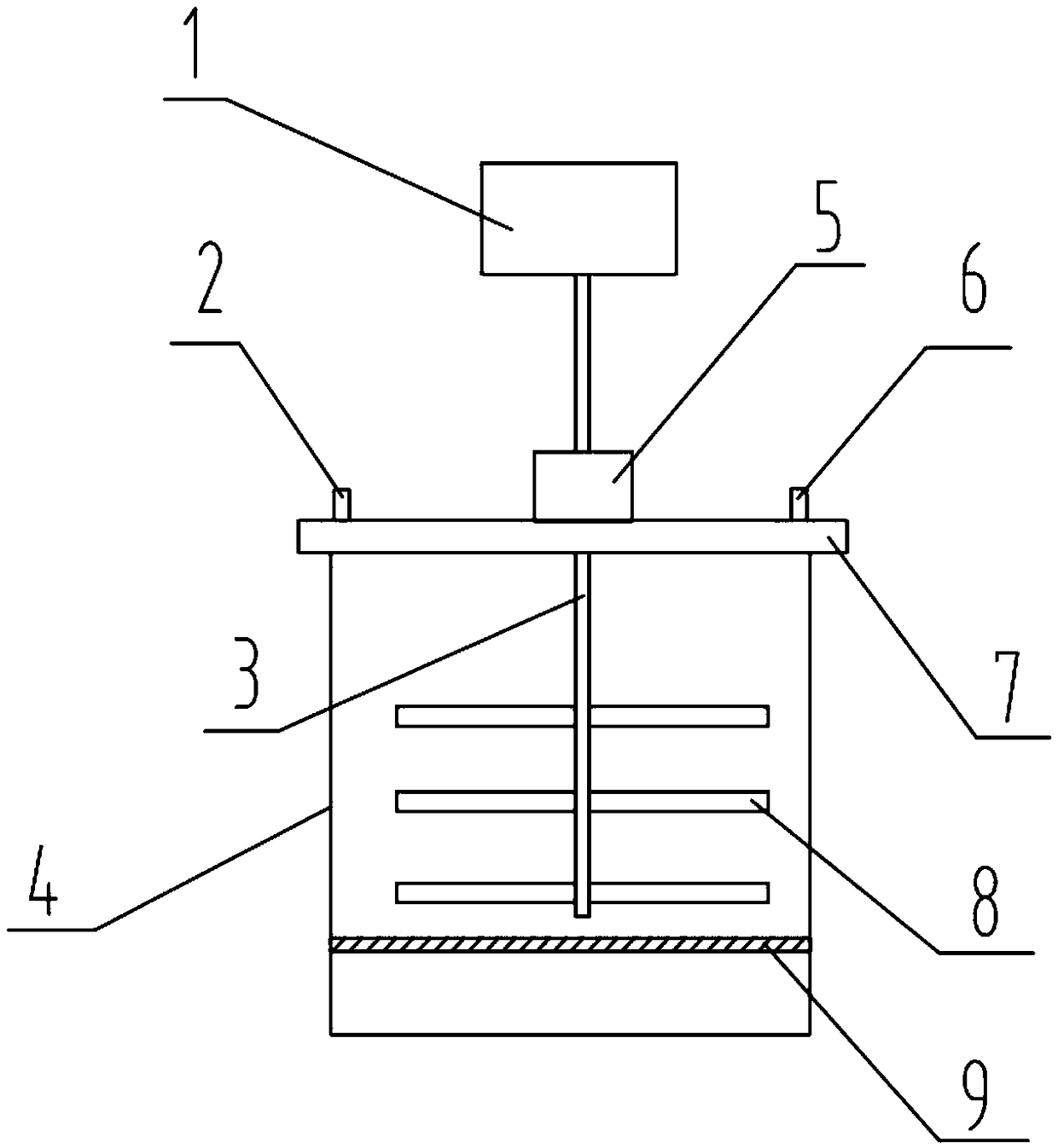

[0023] A device connected to a separation and recovery method of waste tinned copper rice, comprising a motor (1), a rotating shaft (3), and a container (4), one end of the rotating shaft (3) is provided with a stirring paddle (8) and extends to In the cavity of the container, the other end is connected with the motor (1) through the water cooling jacket (7) and the dynamic sealing sleeve (5) in turn; the water cooling jacket (7) is arranged on the top of the container, and the water cooling jacket (7) is respectively A water inlet (2) and a water outlet (6) are provided, and a screen (9) is provided at the bottom of the container, and the screen (9) is made of nickel foam with an aperture of 1 mm.

[0024] Add 1Kg waste tinned copper rice with a wire diameter of 2-4m and a length of 5-12mm and 100mL diesel oil into the container. The diesel oil enters the cavity below the screen in the container. After the diesel oil is added to the bottom of the container, the liquid level do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com