Microwave synthesis method of boron carbide ceramics

A technology of boron carbide ceramics and microwave synthesis, applied in the field of ceramic materials, can solve the problems of high pressureless sintering sintering temperature, difficulty in densification, and difficulty in achieving densification, achieve sintering temperature and sintering time, and the preparation method is simple and convenient, avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

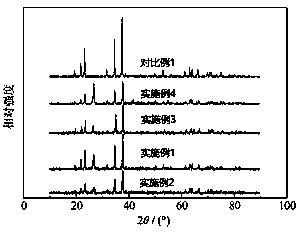

Embodiment 1

[0035] A microwave synthesis method for boron carbide ceramics, comprising the steps of:

[0036] (1) Weigh B in proportion 4 C powder and alumina powder sintering aid, the mass of alumina added is 3% of the mass of boron carbide;

[0037] (2) put B 4 C powder and alumina powder sintering aid are added to the planetary ball mill for wet mixing, adding absolute ethanol as a solvent, the ball-to-material ratio is 10:1, the ball milling speed is 150r / min, ball milling for 3 hours, ball milling is evenly mixed and then dried 100 mesh sieve to obtain mixed powder;

[0038] (3) Stick the graphite paper coated with boron nitride lubricant on the inner wall of the graphite abrasive, and press the sieved mixed powder into the graphite abrasive;

[0039] (4) The powder in the graphite abrasive tool is pre-pressed, pre-pressed to 30MPa, and held for 1min;

[0040] (5) Place the pressed tablet obtained in step (4) in a polycrystalline mullite fiber insulation bucket, and then put the ...

Embodiment 2

[0042] A microwave synthesis method for boron carbide ceramics, comprising the steps of:

[0043] (1) Weigh B4C powder and alumina powder sintering aid in proportion, and the mass of alumina added is 3% of the mass of boron carbide;

[0044] (2) Add B4C powder and alumina powder sintering aid to the planetary ball mill for wet mixing, add absolute ethanol as solvent, the ball-to-material ratio is 10:1, the ball milling speed is 150r / min, ball milling for 3 hours, ball milling and mixing After being uniform, dry and pass through a 100-mesh sieve to obtain a mixed powder;

[0045] (3) Stick the graphite paper coated with boron nitride lubricant on the inner wall of the graphite abrasive, and press the sieved mixed powder into the graphite abrasive;

[0046] (4) The powder in the graphite abrasive tool is pre-pressed, pre-pressed to 30MPa, and held for 1min;

[0047] (5) Place the pressed tablet obtained in step (4) in a polycrystalline mullite fiber insulation bucket, and then...

Embodiment 3

[0049] A microwave synthesis method for boron carbide ceramics, comprising the steps of:

[0050] (1) Weigh B4C powder and alumina powder sintering aid in proportion, and the mass of alumina added is 3% of the mass of boron carbide;

[0051] (2) Add B4C powder and alumina powder sintering aid to the planetary ball mill for wet mixing, add absolute ethanol as solvent, the ball-to-material ratio is 10:1, the ball milling speed is 150r / min, ball milling for 3 hours, ball milling and mixing After being uniform, dry and pass through a 100-mesh sieve to obtain a mixed powder;

[0052] (3) Stick the graphite paper coated with boron nitride lubricant on the inner wall of the graphite abrasive, and press the sieved mixed powder into the graphite abrasive;

[0053] (4) The powder in the graphite abrasive tool is pre-pressed, pre-pressed to 30MPa, and held for 1min;

[0054] (5) Place the pressed tablet obtained in step (4) in a polycrystalline mullite fiber insulation bucket, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com