Wheel rim anticorrosion coating material containing basalt scales, and preparation method thereof

An anti-corrosion coating, basalt technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of poor dispersion and stability, easy settling, coating performance decline, etc., to achieve good resistance to salt spray and reduce infiltration. , Improve the effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

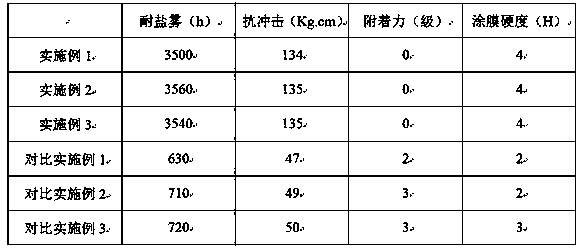

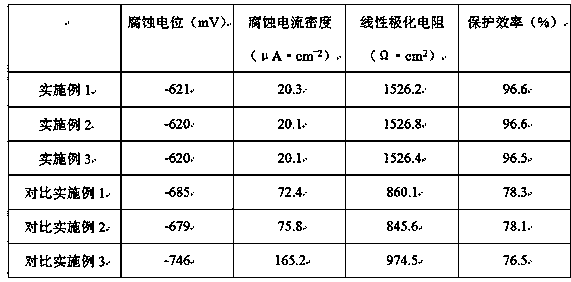

Examples

Embodiment 1

[0023] An anti-corrosion coating for wheel rims containing basalt scales is characterized in that it is made of the following raw materials in parts by weight:

[0024] Basalt flake 10, dilute hydrochloric acid 10, cetyltrimethylammonium bromide 1, aniline solution 30, acidic medium 50, ammonium persulfate 5, water-based epoxy resin 50, calcium carbonate 5, talcum powder 5, orthosilicic acid ethyl ester 10;

[0025] The mass concentration of the dilute hydrochloric acid is 2%.

[0026] Further, its preparation method comprises the following steps:

[0027] (1) Put the basalt scales into a tube furnace, feed nitrogen, raise the temperature to 150°C at a rate of 2°C / min, then roast for 2 hours, then cool down to room temperature at a rate of 4°C / min, and ball mill for 20 minutes until The scale diameter is 5 μm;

[0028] (2) Add the basalt scales obtained in step (1) to 20 times its volume of absolute ethanol, heat to 50°C, treat it under ultrasonic conditions of 65Hz and 100...

Embodiment 2

[0038] An anti-corrosion coating for wheel rims containing basalt scales is characterized in that it is made of the following raw materials in parts by weight:

[0039] Basalt flakes 15, dilute hydrochloric acid 30, cetyltrimethylammonium bromide 2, aniline solution 40, acid medium 70, ammonium persulfate 7, water-based epoxy resin 60, calcium carbonate 10, talcum powder 7, orthosilicic acid ethyl ester 15;

[0040] The mass concentration of the dilute hydrochloric acid is 4%.

[0041] Further, its preparation method comprises the following steps:

[0042] (1) Put the basalt scales into a tube furnace, feed nitrogen, heat up to 155°C at a rate of 3°C / min, then roast for 3 hours, then cool down to room temperature at a rate of 5°C / min, and ball mill for 25 minutes until The scale diameter is 30μm;

[0043] (2) Add the basalt flakes obtained in step (1) to 25 times its volume of absolute ethanol, heat to 55°C, treat it under ultrasonic conditions of 68Hz and 1100W for 35min, ...

Embodiment 3

[0053] An anti-corrosion coating for wheel rims containing basalt scales is characterized in that it is made of the following raw materials in parts by weight:

[0054] Basalt flakes 20, dilute hydrochloric acid 50, cetyltrimethylammonium bromide 3, aniline solution 50, acid medium 100, ammonium persulfate 8, water-based epoxy resin 80, calcium carbonate 15, talcum powder 10, orthosilicic acid ethyl ester 20;

[0055] The mass concentration of the dilute hydrochloric acid is 6%.

[0056] Further, its preparation method comprises the following steps:

[0057] (1) Put the basalt scales into a tube furnace, feed nitrogen, raise the temperature to 160°C at a rate of 4°C / min, then roast for 3 hours, then cool down to room temperature at a rate of 5°C / min, and ball mill for 30 minutes until The scale diameter is 50μm;

[0058] (2) Add the basalt scales obtained in step (1) to 30 times its volume of absolute ethanol, heat to 60°C, treat it under ultrasonic conditions of 70Hz and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com