Modified electrode and electrochemical detection method for sulpiride

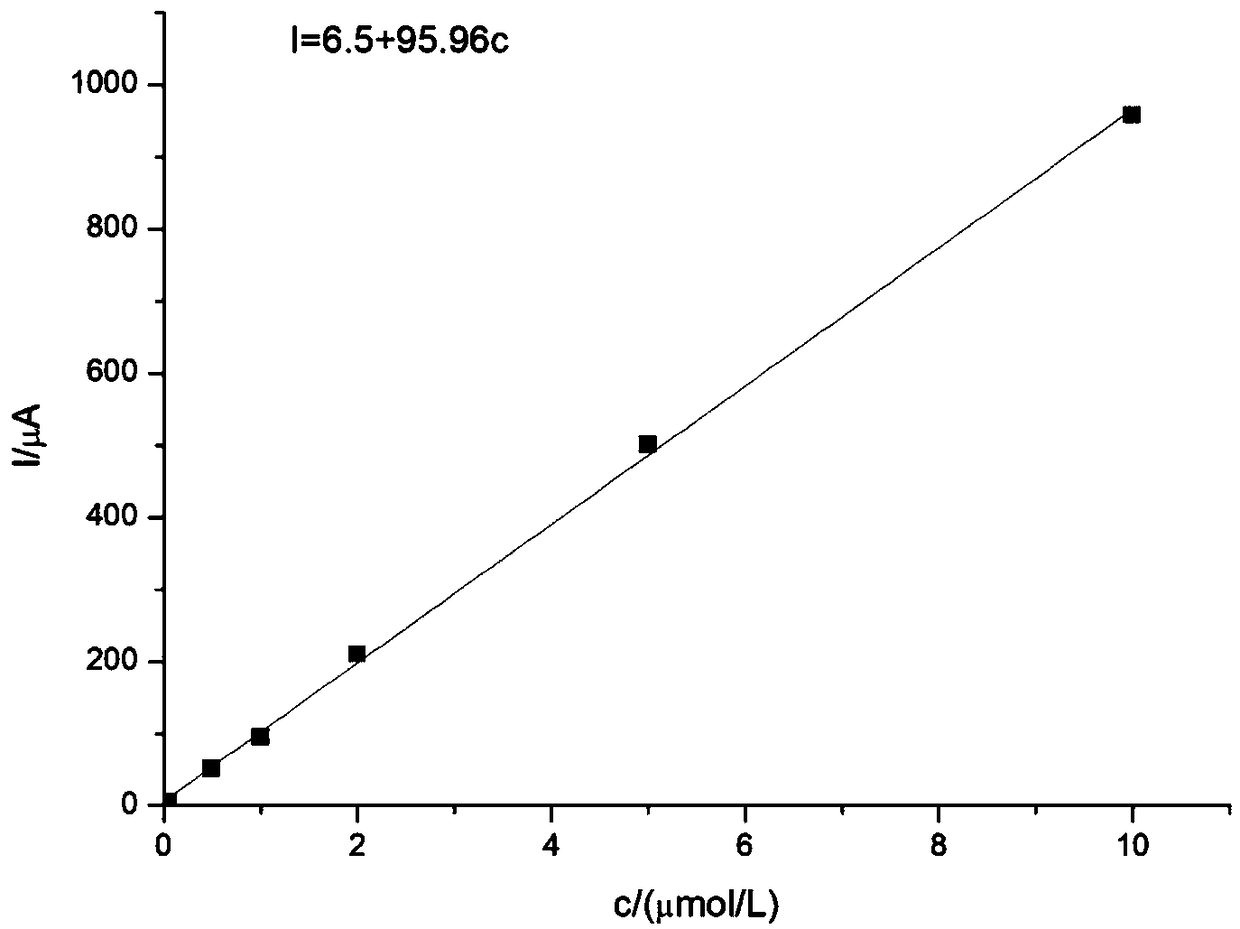

A glassy carbon electrode, -moo3 technology, applied in the direction of material electrochemical variables, measuring devices, scientific instruments, etc., can solve the problems of low efficiency, long analysis time, high catalytic activity of sulpiride, etc., and achieve strong application value and electrochemical activity. High, sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of α-MoO 3 Nanorod modified glassy carbon electrode:

[0025] (1) α-MoO 3 Preparation of powder: ultrasonically disperse anhydrous sodium molybdate and hydrochloric acid in deionized water at a molar ratio of 1:3, then transfer the dispersion to a polytetrafluoroethylene high-pressure reactor, and place the reactor in a heating device 1 h at 150°C, cooled naturally to room temperature, filtered, dried, and then placed in a tube furnace and calcined at 350°C for 1 h in an air atmosphere to obtain α-MoO 3 powder;

[0026] (2) Glassy carbon electrode pretreatment: the glassy carbon electrode was polished with 0.1 μm and 0.05 μm alumina powder for 2 minutes in turn, and polished to a mirror surface, and the polished glassy carbon electrode was ultrasonically cleaned with acetone and deionized water for 3 minutes, respectively, to obtain Pretreated glassy carbon electrodes;

[0027] (3)α-MoO 3 Nanorod-modified glassy carbon electrodes: using prepared α-MoO ...

Embodiment 2

[0029] Preparation of α-MoO 3 Nanorod modified glassy carbon electrode:

[0030] (1) α-MoO 3 Powder preparation: ultrasonically disperse anhydrous sodium molybdate and hydrochloric acid in deionized water at a molar ratio of 1:7, then transfer the dispersion to a polytetrafluoroethylene high-pressure reactor, and place the reactor in a heating device In 190°C, hydrothermal reaction was carried out for 4h, naturally cooled to room temperature, filtered, dried, then placed in a tube furnace, and calcined at 500°C for 4h in an air atmosphere to obtain α-MoO 3 powder;

[0031] (2) Glassy carbon electrode pretreatment: the glassy carbon electrode was polished with 0.1 μm and 0.05 μm alumina powder for 2 minutes in turn, and polished to a mirror surface, and the polished glassy carbon electrode was ultrasonically cleaned with acetone and deionized water for 3 minutes, respectively, to obtain Pretreated glassy carbon electrodes;

[0032] (3)α-MoO 3 Nanorod-modified glassy carbon...

Embodiment 3

[0034] α-MoO 3 Preparation of nanorod modified glassy carbon electrodes:

[0035] (1) α-MoO 3 Preparation of powder: ultrasonically disperse anhydrous sodium molybdate and hydrochloric acid in deionized water at a molar ratio of 1:5, then transfer the dispersion to a polytetrafluoroethylene high-pressure reactor, and place the reactor in a heating device in 170°C for 2h, cooled to room temperature naturally, filtered, dried, and then placed in a tube furnace, calcined at 400°C for 2h in an air atmosphere to obtain α-MoO 3 powder;

[0036] (2) Glassy carbon electrode pretreatment: the glassy carbon electrode was polished with 0.1 μm and 0.05 μm alumina powder for 2 minutes in turn, and polished to a mirror surface, and the polished glassy carbon electrode was ultrasonically cleaned with acetone and deionized water for 3 minutes, respectively, to obtain Pretreated glassy carbon electrodes;

[0037] (3)α-MoO 3 Nanorod-modified glassy carbon electrodes: using prepared α-MoO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com