Flexible self-expansion temperature-resistant sealing element for continuously casted long nozzle and preparation method thereof

A sealing element and self-expanding technology, which is applied in the direction of casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problem that continuous casting steel shroud sealing cannot be applied, continuous casting shroud high-temperature sealing cannot be applied, and self-expanding separation is not available Performance and other issues, to achieve the effect of good sealing, low price and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The above-mentioned preparation method of the flexible self-expanding heat-resistant sealing element for continuous casting shroud comprises the following steps:

[0045] Step 1. Prepare the flexible self-expanding inorganic sealing material and sintering aids, antioxidants, dispersants, film-forming aids and flame retardants according to mass percentages and put them into a mixer or mud mixer. Slowly add a liquid organic binder and fully wet mill to obtain the flexible self-expanding inorganic sealing material;

[0046] Step 2. Feed the flexible self-expanding inorganic sealing material into the stamping die through a mud extruder or manual feeding, close the molds and punch out the body of the flexible self-expanding inorganic sealing material;

[0047] Step 3. After demoulding, support the body of the flexible self-expanding inorganic sealing material with a support kit and move it into a curing / vulcanizing furnace or on a natural drying bench. After curing, the fini...

Embodiment 1

[0051] As shown in Table 1, with 70% alumina aggregate and fine powder, 13% quartz fine powder, 10% clay fine powder, 5% chopped glass fiber, 1% expanded graphite and 1% Flake graphite is the main raw material, plus 2% sintering aid powder, 3% antioxidant powder and 1% dispersant powder, fully stir in the mixer, and then add 15% liquid phenolic resin and 3% epoxy resin premix , and high-speed stirring to prepare flexible self-expanding heat-resistant sealing mud. The fully wet-milled mud is put into the mold through a mud extruder or manual feeding, and the designed shape is stamped out. The graphite paper can be pasted on the stamping male mold in advance. After demolding, products that cannot be self-sustaining can be used with support kits and moved into a curing / vulcanizing oven or a natural drying bench. Graphite paper can also be adhered to the outer surface of the product with a binder after demoulding or curing.

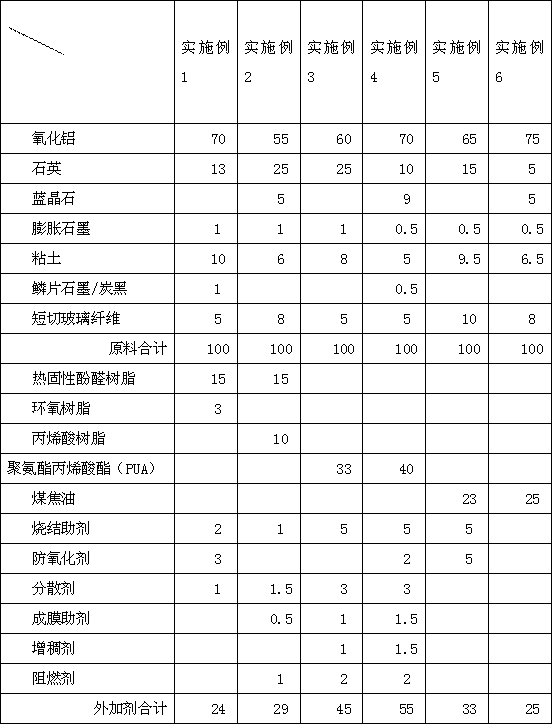

Embodiment 2~ Embodiment 6

[0053] The method is the same as in Example 1, except that different mass parts of raw materials and additives are used, and different binder systems are used.

[0054] Table 1 Formulation of flexible self-expanding heat-resistant sealing elements for continuous casting shrouds (wt%)

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com