Preparation method of TiB2 ceramic powder

A technology of ceramic powder and reducing agent, which is applied in the field of preparation of TiB2 ceramic powder, can solve the problems of acid treatment, purification and purification process, environmental pollution, inability to accurately control the product stoichiometric ratio, complex purification and treatment of reaction products, etc., and achieve improved thermodynamics conditions, environmentally friendly industrial production, and the effect of broadening the source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

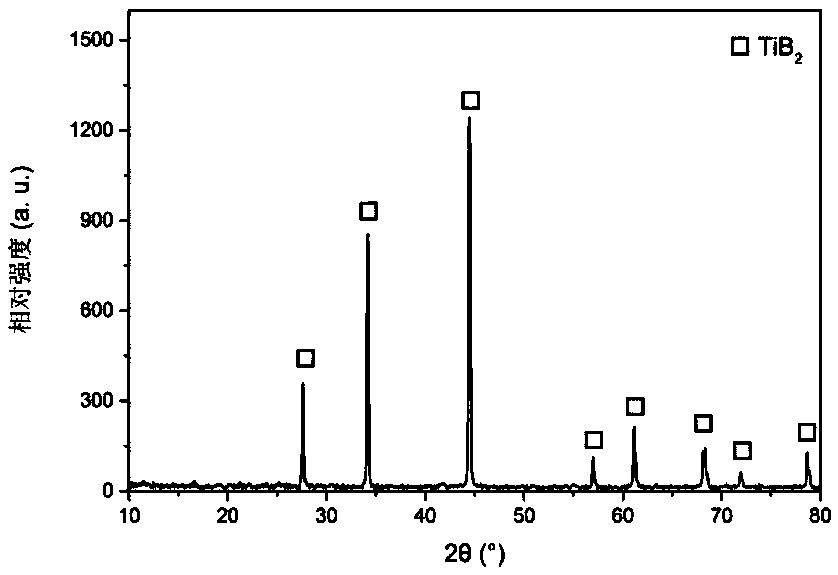

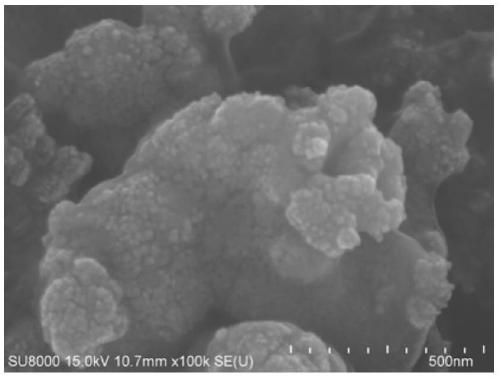

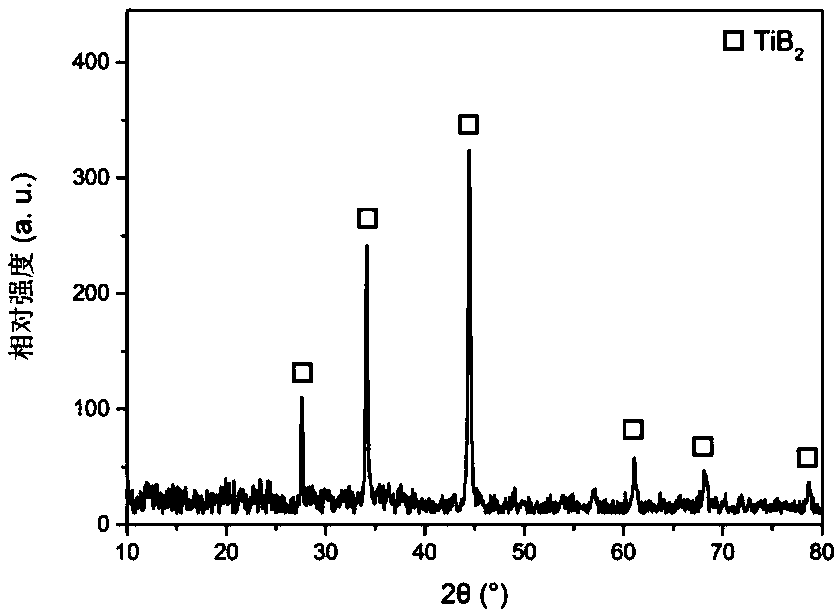

Image

Examples

Embodiment 1

[0037] a TiB 2 Preparation method of ceramic powder. The preparation method described in this embodiment is: by reducing agent: titanium source: boron source: the mass ratio of alkali metal compound molten salt is 1.0: (0.7~1.0): (0.7~1.7): (0.2~5.0), will The reducing agent, the titanium source, the boron source and the molten salt of the alkali metal compound are uniformly mixed, heat-treated in a protective atmosphere at 1000-1300°C for 6-8 hours, and then heated with water at 95-200°C dissolved, washed, and dried to obtain TiB 2 Ceramic powder.

[0038] The reducing agent is more than one of silicon powder and aluminum powder.

[0039] The titanium source is Ti powder and TiO 2 More than one type of powder.

Embodiment 2

[0041]a TiB 2 Preparation method of ceramic powder. The preparation method described in this embodiment is: by reducing agent: titanium source: boron source: the mass ratio of alkali metal compound molten salt is 1.0: (0.7~1.0): (0.7~1.7): (0.2~5.0), will The reducing agent, the titanium source, the boron source and the molten salt of the alkali metal compound are uniformly mixed, heat-treated in a protective atmosphere at 1000-1300°C for 6-8 hours, and then heated with an alkali solution at 95-200 Dissolved at ℃, washed and dried to obtain TiB 2 Ceramic powder.

[0042] The reducing agent is silicon powder.

[0043] The titanium source is Ti powder.

Embodiment 3

[0045] a TiB 2 Preparation method of ceramic powder. The preparation method described in this embodiment is: by reducing agent: titanium source: boron source: the mass ratio of alkali metal compound molten salt is 1.0: (0.7~1.0): (0.7~1.7): (0.2~5.0), will The reducing agent, the titanium source, the boron source and the molten salt of the alkali metal compound are uniformly mixed, heat-treated in a protective atmosphere at 1000-1300°C for 6-8 hours, and then heated with an alkali solution at 95-200 Dissolved at ℃, washed and dried to obtain TiB 2 Ceramic powder.

[0046] The reducing agent is aluminum powder.

[0047] The titanium source is TiO 2 pink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com