A kind of direct-coated pvc protective film based on acrylate macromonomer and preparation method thereof

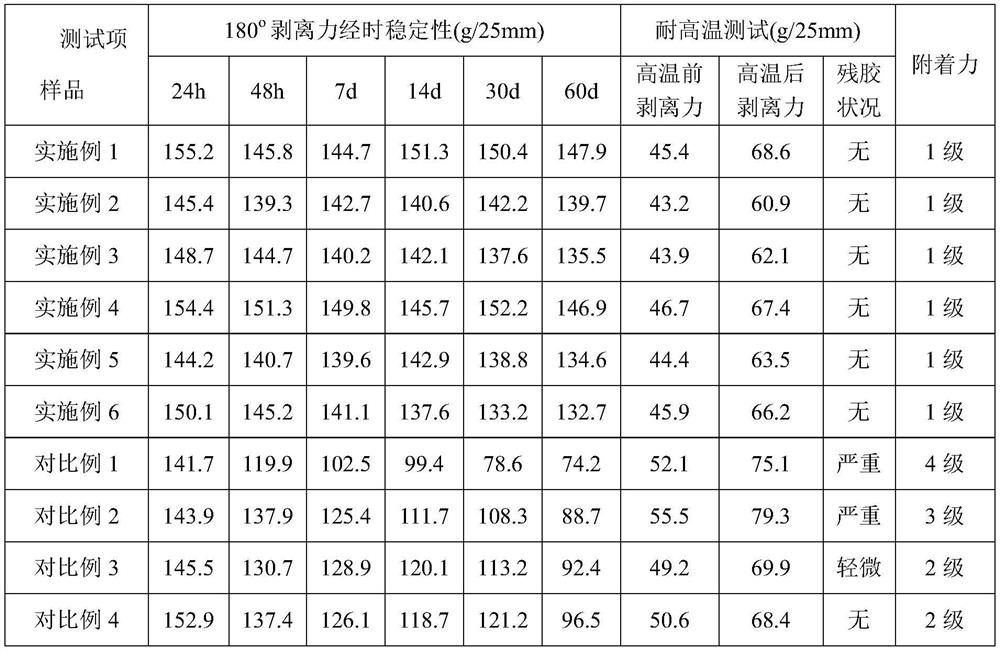

A technology of macromolecular monomer and methacrylate, which is applied in the direction of adhesive type, pressure-sensitive film/sheet, film/sheet-shaped adhesive, etc., and can solve pressure-sensitive adhesive layer softening, peeling off, stickiness Fading and other problems, to achieve the effect of excellent adhesion, enhanced binding force, long-term stability and non-attenuation of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of preparation method based on acrylate macromolecular direct coating type PVC protective film

[0024] 1) Functionalization of chlorine-containing polymers

[0025] Add 50 parts of toluene and 75 parts of ethyl acetate mixed solvent into the reaction kettle, add 40 parts of chloroprene rubber under stirring, raise the temperature to dissolve it completely; 1 part of methyl methacrylate, 30 parts of tetrahydrofuryl acrylate, 10 parts of hydroxyethyl acrylate, 0.5 parts of azobisisobutyronitrile and 25 parts of ethyl acetate, the time for adding is 1 hour; ℃ for 2 hours, and then add 0.2 parts of hydroquinone to terminate the reaction to obtain a functionalized chlorine-containing high polymer.

[0026] 2) Synthesis of acrylate macromolecular copolymer

[0027] Add 10 parts of isocyanoethyl methacrylate and 0.01 part of dibutyltin dilaurate to the functionalized chlorine-containing high polymer prepared in step 1), stir and react at 80°C for 1 hour...

Embodiment 2

[0032] Embodiment 2: A kind of preparation method based on acrylate macromolecular direct coating type PVC protective film

[0033] 1) Functionalization of chlorine-containing polymers

[0034] Add 50 parts of toluene and 75 parts of ethyl acetate mixed solvent into the reaction kettle, add 40 parts of chlorobenzene rubber under stirring, and heat up to dissolve it completely; at 80±2°C, start to add 20 parts of 1 part of methyl methacrylate, 30 parts of n-butyl methacrylate, 10 parts of hydroxyethyl methacrylate, 0.5 parts of azobisisoheptanonitrile and 25 parts of ethyl acetate mixed monomers, the time of dropping is 1 hour; After dropping, keep warm at 80° C. for 2 hours, and then add 0.2 parts of hydroquinone to terminate the reaction to obtain a functionalized chlorine-containing high polymer.

[0035] 2) Synthesis of acrylate macromolecular copolymer

[0036] Add 10 parts of isocyanoethyl methacrylate and 0.01 part of dibutyltin dibutyrate successively to the functiona...

Embodiment 3

[0041] Embodiment 3: A kind of preparation method based on acrylate macromolecular direct coating type PVC protective film

[0042] 1) Functionalization of chlorine-containing polymers

[0043] Add 50 parts of toluene and 75 parts of ethyl acetate mixed solvent into the reaction kettle, add 40 parts of chlorinated rubber under stirring, and raise the temperature to dissolve it completely; at 80±2°C, start to add 20 1 part of methyl methacrylate, 30 parts of isobornyl acrylate, 10 parts of acrylic acid, 0.5 parts of benzoyl peroxide and 25 parts of ethyl acetate, dropwise for 1 hour; after dropping, keep warm at 80°C for reaction After 2 hours, 0.2 parts of hydroquinone was added to terminate the reaction to obtain a functionalized chlorine-containing high polymer.

[0044] 2) Synthesis of acrylate macromolecular copolymer

[0045] Add 10 parts of isocyanoethyl methacrylate and 0.01 part of dibutyltin diacetate to the functionalized chlorine-containing high polymer prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com