Titanium/steel dissimilar metal plasma shunt melting electrode arc brazing device and method based on pulse coordination control

A technology of coordinated control and dissimilar metals, applied in arc welding equipment, auxiliary devices, metal processing, etc., can solve problems such as easy oxidation of titanium and brazing seams, unfavorable economic requirements, large heat-affected zone, etc., to achieve improved Mechanical properties, beautiful forming, and high melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

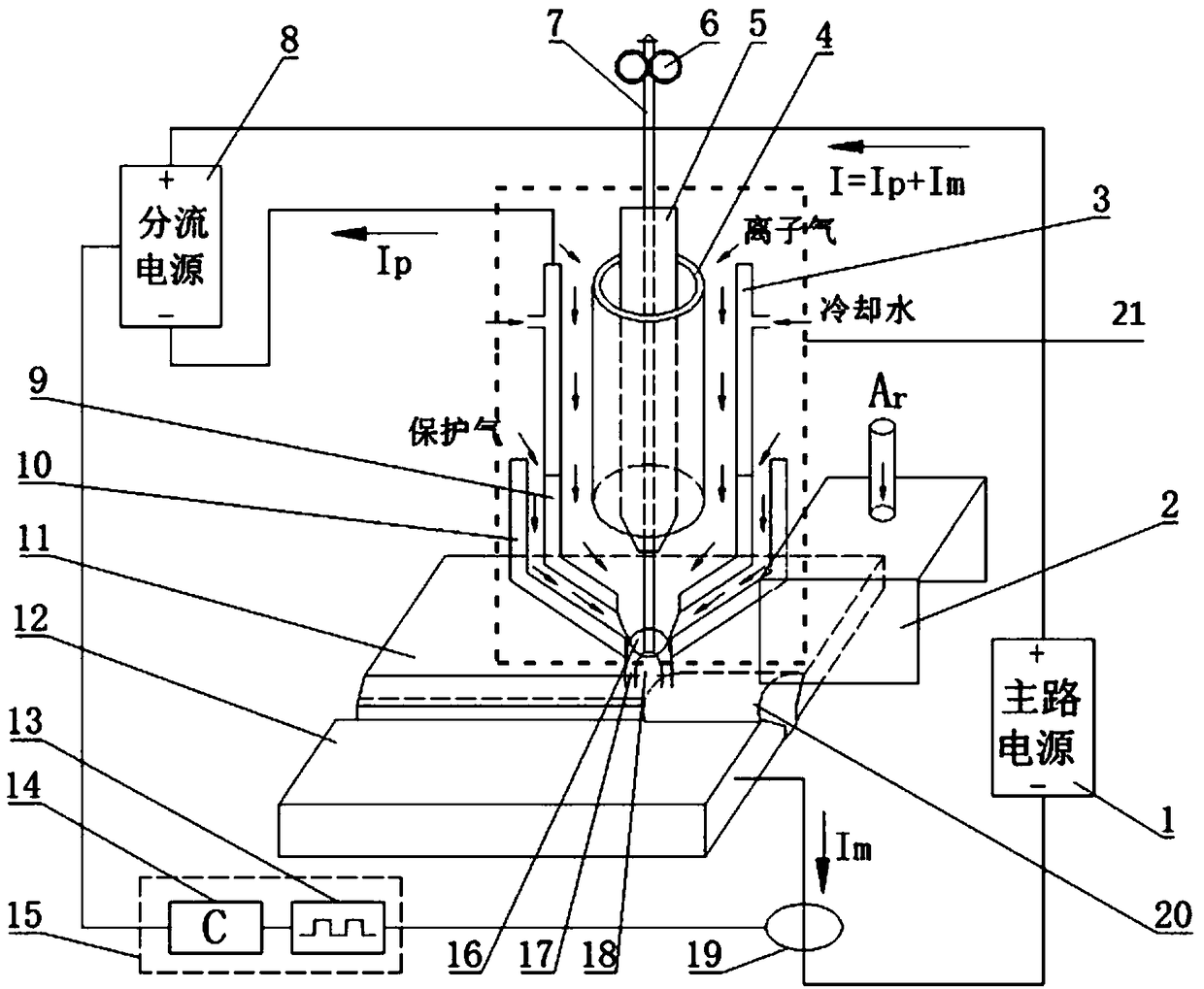

[0026] Aiming at the problems of easy formation of brittle intermetallic compounds, poor joint performance, high cost, complex equipment, and poor stability during titanium / steel welding, a titanium / steel dissimilar metal plasma shunt molten electrode arc brazing device based on pulse coordinated control was proposed and methods.

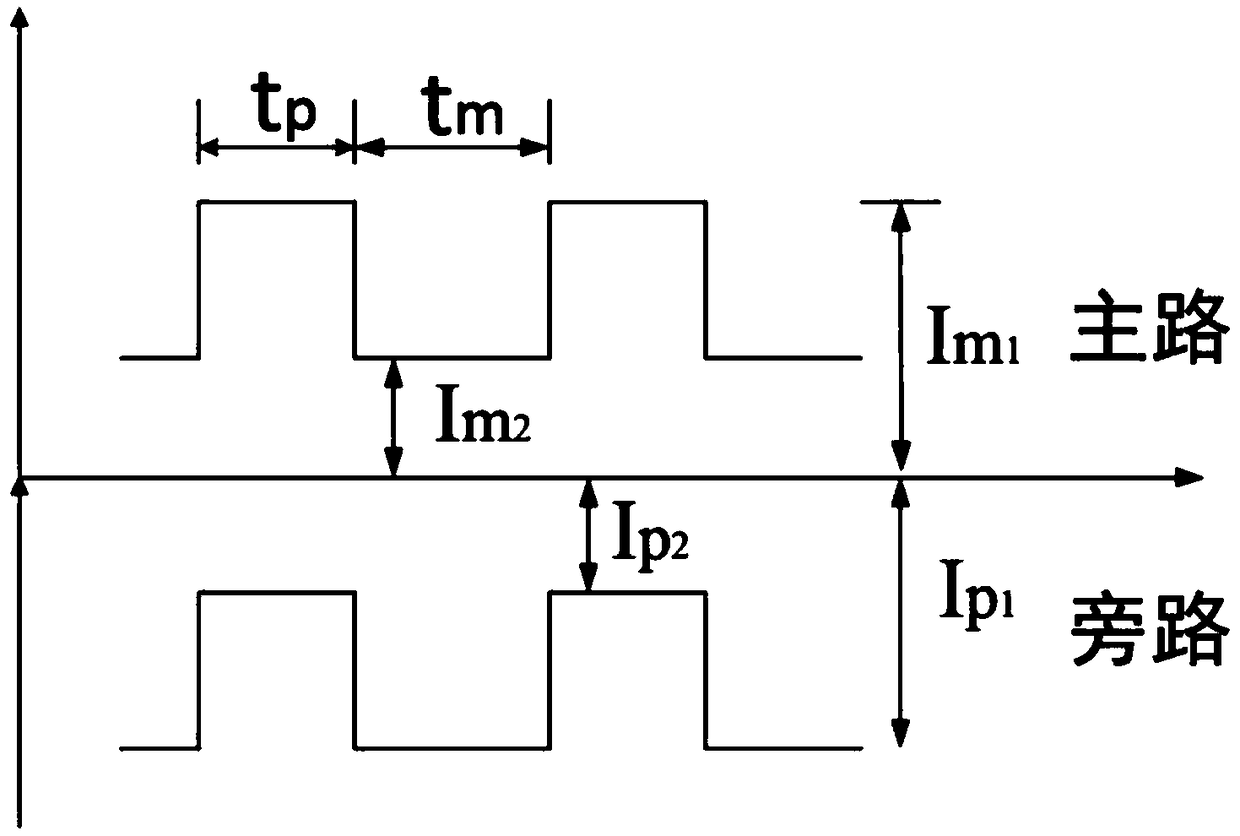

[0027] The present invention is a titanium / steel dissimilar metal plasma split melting electrode arc brazing method based on pulse coordination control. Composition of welding torch, wire feeding mechanism, current sensor, etc. During the welding process, the method of pulse coordination control is adopted, that is, when the main circuit current is the base value, the shunt current is also the base value, which can ensure the stability of the coupling arc during welding; when the main circuit current is the peak value, the shunt current is also peak, which ensures low workpiece heat input during welding for a stable and reliable welding process. D...

Embodiment 2

[0033] combine figure 1, which is an embodiment of titanium / steel butt joint plasma shunt melting electrode arc brazing based on pulse coordinated control. Contact tip 5, wire feeding mechanism 6, solder wire 7, shunt power supply 8, plasma nozzle 9, protective gas cover 10, titanium plate 11, steel plate 12, pulse signal processor 13, signal controller 14, pulse coordination control system 15 , current sensor 19, plasma shunt melting electrode torch 21 and other components. During the welding process, the positive pole of the main power supply 1 is connected to the solder wire 7, and the negative pole is connected to the workpiece; the positive pole of the shunt power supply 8 is connected to the solder wire 7, and the negative pole is connected to the water-cooled copper sleeve 3, and the plasma arc 16 is connected to the plasma nozzle 8 to form a shunt circuit; During the welding process, the MIG arc 18 and the plasma arc 16 are coupled to form a composite arc 17; the puls...

Embodiment 3

[0041] combine figure 2 , which is an embodiment of plasma shunt molten electrode arc brazing of titanium / steel lap joints based on pulse coordinated control. , conductive tip 5, wire feeding mechanism 6, solder wire 7, shunt power supply 8, plasma nozzle 9, protective gas cover 10, titanium plate 11, steel plate 12, pulse signal processor 13, signal controller 14, pulse coordination control system 15. Current sensor 19, plasma shunt melting electrode torch 21 and other components. During the welding process, the positive pole of the main power supply 1 is connected to the solder wire 7, and the negative pole is connected to the workpiece; the positive pole of the shunt power supply 8 is connected to the solder wire 7, and the negative pole is connected to the water-cooled copper sleeve 3, and the plasma arc 16 is connected to the plasma nozzle 8 to form a shunt circuit; During the welding process, the main arc 18 and the plasma arc 16 are coupled into a composite arc 17; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com