Preparation method of corrosion-resistant antibacterial and anti-biofouling multifunctional metal-based protective coating

A protective coating and anti-biological technology, applied in the field of preparation of multi-functional metal-based protective coatings, can solve the problems of corrosion of marine organisms, fouling, corrosion resistance, antibacterial and anti-biological fouling of metal materials, and achieve excellent corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In the specific implementation process, the preparation method of the corrosion-resistant, anti-bacterial, anti-biofouling and anti-biofouling multifunctional metal-based protective coating comprises the following steps:

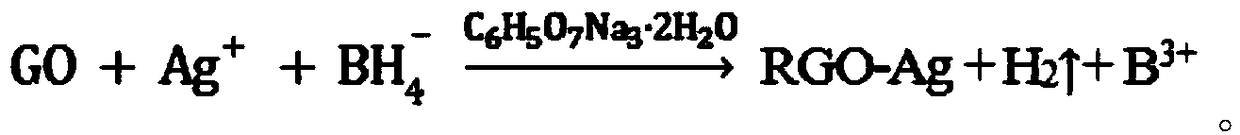

[0027] Step 1, preparation of graphene / nano-silver composite powder: in-situ synthesis of nano-silver on graphene oxide by chemical reaction, reduction to obtain graphene / nano-silver composite powder with different composition ratios, the weight of graphene oxide and silver nitrate raw materials The ratio is 5:1~1:5 (preferably 2:1~1:2);

[0028] Step 2, ball milling and mixing: adopt ball milling technology to mix the graphene / nano-silver composite powder obtained in step 1 with metal-based powder, the metal powders used are Al, Zn and their alloy powders, the metal powder and graphene / nano-silver The weight ratio is 20:1-200:1 (preferably 50:1-100:1). The ball milling conditions are: under the protection of inert gas (argon or helium), the grinding...

Embodiment 1

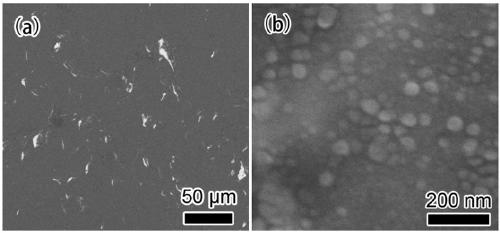

[0033] In this embodiment, chemical reaction is used to synthesize nano-silver (with a particle size of 5-40nm) in situ on graphene oxide, the weight ratio of raw material graphene oxide and silver nitrate is 1:1, and the Al powder (with a particle size of 25~38μm), mixed with graphene / nano-silver composite powder (the particle size of composite powder is 10-50μm, the mass ratio of graphene and nano-silver composite powder is 1:1), and three kinds of stainless steel balls of 1mm, 3mm and 9mm are used for ball milling ( The mass ratio of three kinds of stainless steel balls is 1:1:1), the mass ratio of ball to material is 10:1, the rotating speed is 100rpm, and the weight ratio of Al powder to graphene / nano-silver composite powder is 50:1 to obtain Al / graphite Alkene / nano-silver composite powder (composite powder particle size 25-38μm). The composite powder after ball milling was heat-treated at 250°C for 3 hours under the protection of argon, and the composite powder was depos...

Embodiment 2

[0036]In this example, a chemical reaction is used to synthesize nano-silver (with a particle size of 5-40nm) in situ on graphene oxide, the weight ratio of raw material graphene oxide and silver nitrate is 1:1, and the Al-Mg alloy powder (particle size is 25~38 μm, Mg content is 0.5~2.5wt%), mixed with graphene / nano-silver composite powder (composite powder particle size is 10~50 μm, the mass ratio of graphene and nano-silver composite powder is 1:1), The ball mill adopts three kinds of stainless steel balls of 1mm, 3mm and 9mm (the mass ratio of the three kinds of stainless steel balls is 1:1:1), the mass ratio of the ball to material is 15:1, the speed is 150rpm, Al-Mg alloy powder and graphene / nano The weight ratio of the silver composite powder is 50:1, and the Al-Mg / graphene / nano-silver composite powder (composite powder particle size 25-38 μm) is obtained. The composite powder after ball milling was heat-treated at 300°C for 3 hours under the protection of argon, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com