Extruding wheel of continuous extruding machine

A technology of extrusion wheel and extrusion machine, applied in metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problem of extrusion wheel scrapping, reduce stress value, and reduce equipment operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

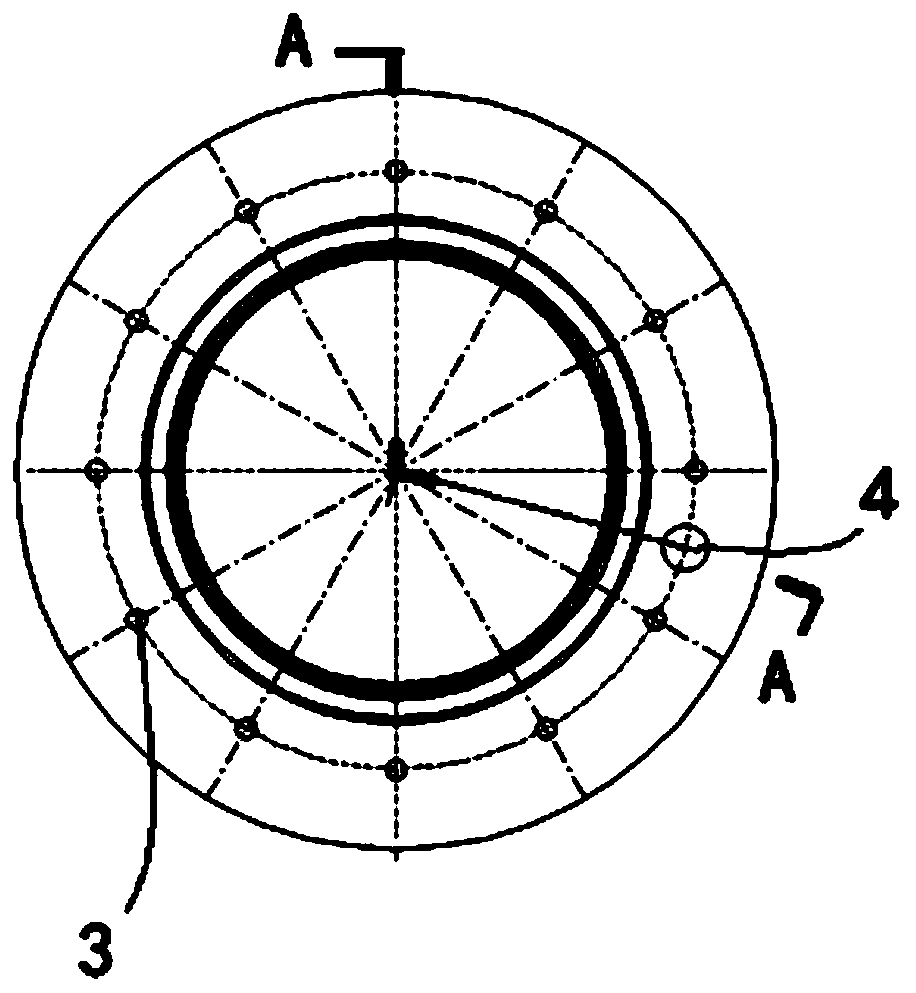

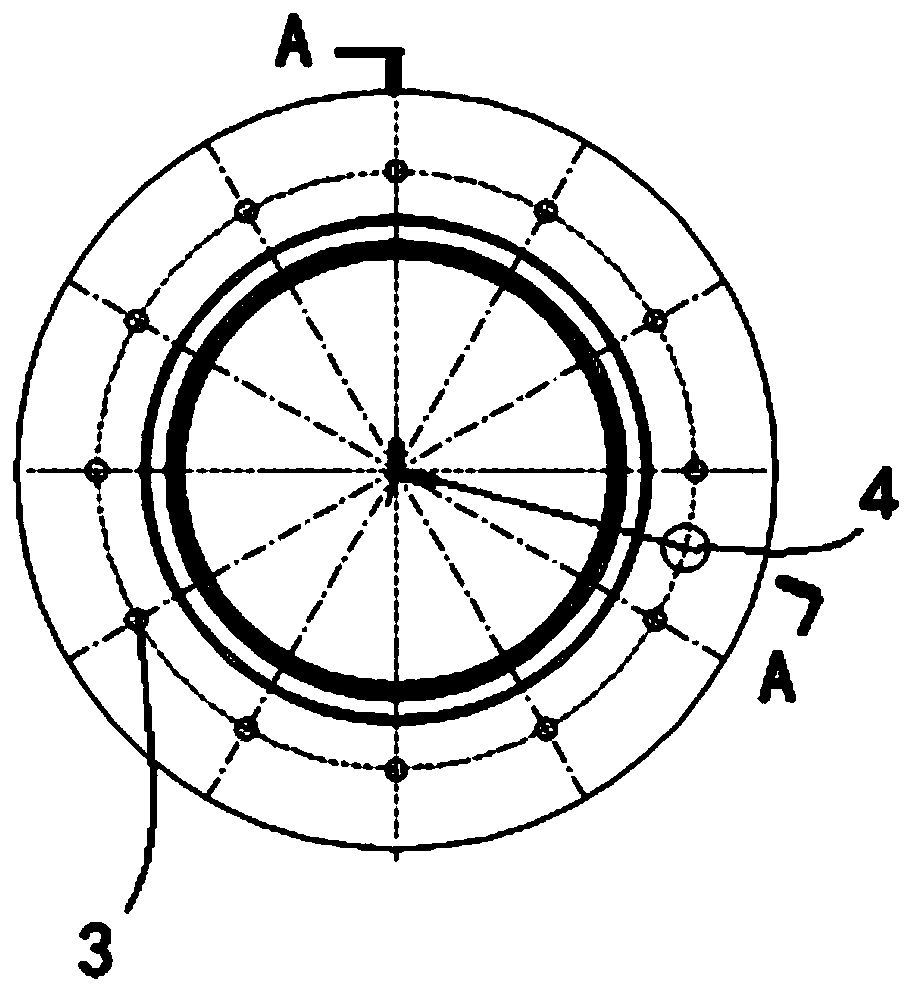

[0016] Such as Figure 1-Figure 2 As shown, an extrusion wheel of a continuous extrusion machine, the extrusion wheel 1 is provided with a circular groove 2 in the circumferential direction, and the extrusion wheel 1 is distributed along the circumferential direction with a plurality of grooves passing through the extrusion wheel 1. Cooling through hole 3, there is a distance H between the center line of the cooling through hole 3 and the bottom of the groove 2, and the center line of the cooling through hole 3 is perpendicular to the end face of the extrusion wheel, that is, the center line of the cooling through hole 3 and the extrusion wheel 1 The centerlines are parallel, and the end face of the extrusion wheel is provided with a pin hole 4 that does not go through the extrusion wheel 1 .

[0017] The diameter D of the cooling through hole 3 is 10 mm, the distance H between the center line of the cooling through hole 3 and the bottom of the groove is 28 mm, and the number ...

Embodiment 2

[0020] The structure and connection relationship of each part of the extrusion wheel of a continuous extrusion machine described in this embodiment are the same as those in Example 1, the difference is that the cooling through hole 3 is 15° from the axis of the extrusion wheel 1. °; the diameter of the cooling through hole 3 is 6 mm, the distance H from the centerline of the cooling through hole 3 to the bottom of the groove is 15 mm, and the number of cooling through holes 3 is 20; the number of the pin hole 4 is 1 ; The inner hole of the extrusion wheel is provided with circular arc grooves for installing transmission keys to transmit torque, the number of the circular arc grooves is 4-16, and the radius of the circular arc grooves is 4-20mm.

Embodiment 3

[0022] The structure and connection relationship of each part of the extrusion wheel of a continuous extrusion machine described in this embodiment are the same as those in Example 1, the difference is: the cooling through hole 3 is 30 degrees to the axis of the extrusion wheel 1 °; the diameter of the cooling through hole 3 is 15mm, the distance H between the centerline of the cooling through hole 3 and the bottom of the groove is 40mm, and the number of cooling through holes 3 is 8; the number of the pin holes 4 is 16 ; The inner hole of the squeeze wheel is provided with internal splines for torque transmission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com