A Method for Improving the Quality of Al-cu Dissimilar Metal Friction Stir Welded Butt Joints

A technology of friction stir welding and dissimilar metals, which is applied in the direction of welding/welding/cutting articles, welding equipment, metal processing equipment, etc., and can solve the problem of not significantly improving the welding quality of friction stir welding joints of Al-Cu dissimilar metals, joint machinery There is no obvious improvement in performance, etc., to achieve the effect of improving mechanical properties, simple machining, and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

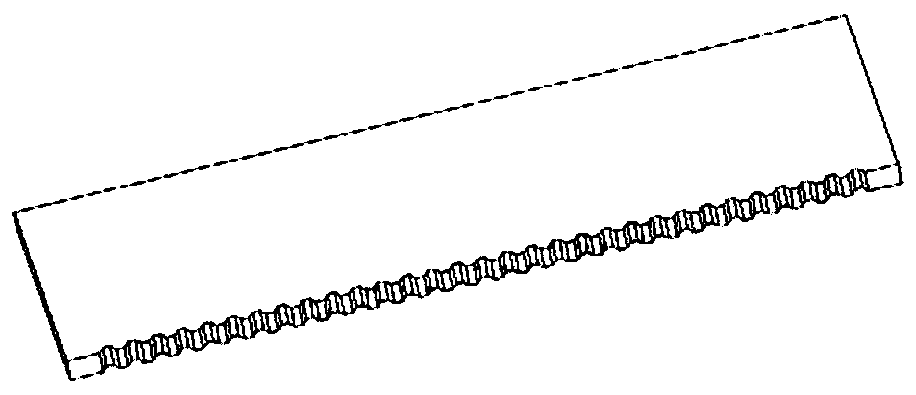

[0023] 1) Processing of weldments with serrated edges: Take one piece of 6061-T6 aluminum alloy and T2 copper plate with a length of 100 mm, a width of 50 mm, and a thickness of 4 mm, and press the edge of the two plates along the welding butt joint edge on the butt joint surface The trapezoidal sawtooth is processed along the normal line of the weld and distributed in array along the welding length direction. The long side of the trapezoid is 3.00 mm long, the short side is 1.27 mm long, and the height is 1.5 mm. The interval between each sawtooth is 1.5 mm.

[0024] Use sandpaper to remove the oxide skin on the surface of the welding and serrated edges, and then wipe with alcohol to remove the oil stains and other impurities on the weldment.

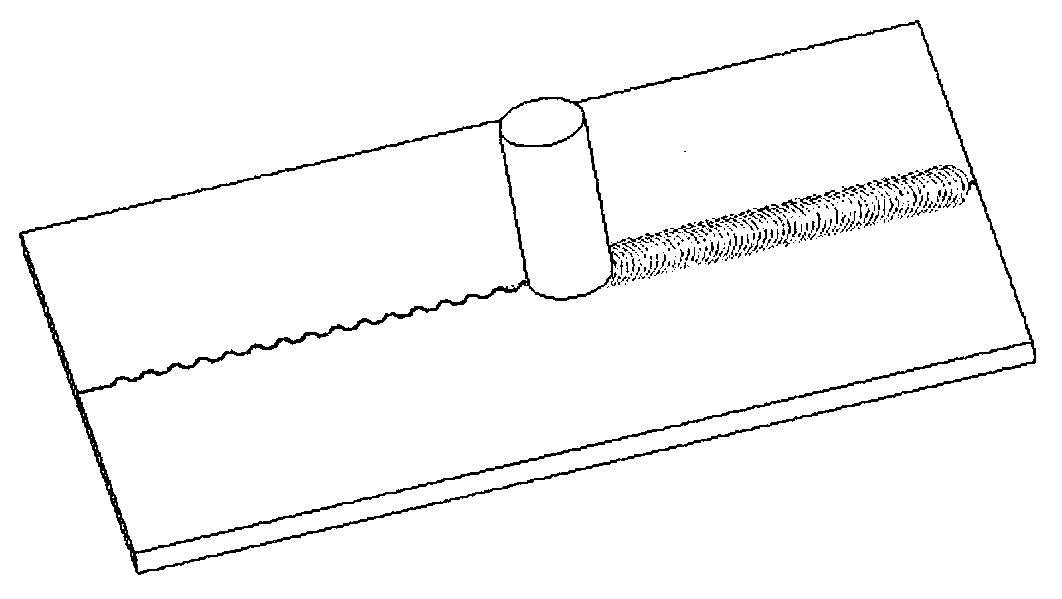

[0025] 2) Friction stir welding: Firstly, the two weldments processed above are butted together along the sawtooth edge. Misalignment and offset are not allowed in the butt joint of the sawtooth, and the maximum butt gap is less than 0....

Embodiment 2

[0028] 1) Processing of weldments with serrated edges: Take a piece of 7075 aluminum alloy and a brass plate with a length of 100 mm, a width of 50 mm, and a thickness of 5 mm. The trapezoidal sawtooth is machined in the normal direction and arrayed along the welding length direction. The long side of the trapezoid is 3.00 mm, the short side is 1.27 mm, and the height is 1.5 mm. The interval between each sawtooth is 1.5 mm.

[0029] Use sandpaper to remove the oxide skin on the welding surface, and then wipe with alcohol to remove oil and other impurities on the test plate.

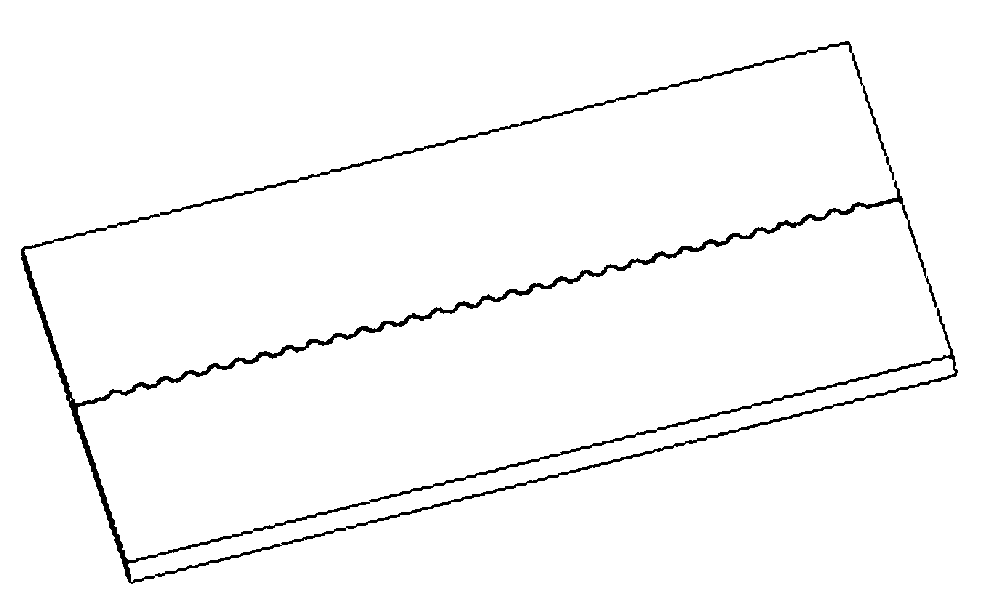

[0030] 2) Perform friction stir welding: butt the two processed test plates along the sawtooth edge, the butt joint sawtooth is not allowed to have misalignment and offset, and the maximum butt joint gap does not exceed 0.25 mm. The length direction of the weld seam when viewed from the top of the butt welded parts is as follows: figure 2 The jagged edges shown are visible, and then the butt-connected t...

Embodiment 3

[0033] 1) Processing of weldments with serrated edges: Take industrial pure aluminum and T2 copper pipe fittings with a diameter of 500, a length of 250 mm, and a thickness of 3 mm. The trapezoidal sawtooth is processed in an array distribution along the length direction. The long side of the trapezoidal sawtooth is 3.00 mm, the short side is 1.27 mm, and the height is 1.5 mm.

[0034] Use sandpaper to remove the oxide skin on the welding surface, and then wipe with alcohol to remove oil and other impurities on the test plate.

[0035] 2) Friction stir welding: butt the above-mentioned two pipe fittings along the sawtooth edge, the butt joint serrations are not allowed to have misalignment and offset, and the maximum butt joint gap is less than 0.15 mm. The welded parts after butt joint can be seen along the sawtooth edge of the weld seam on the surface of the pipe fittings when viewed from above, and then the butt welded parts are clamped on the friction stir welding machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com