ScB2-B superhard composite film and preparation method thereof

A composite thin film, scb2-b technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of rare preparation processes, achieve the elimination of surface roughness, strong adjustability, and reduce deposition The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A ScB 2 -B superhard composite film, the chemical formula is 0.78ScB 2 -0.22B superhard composite material composition.

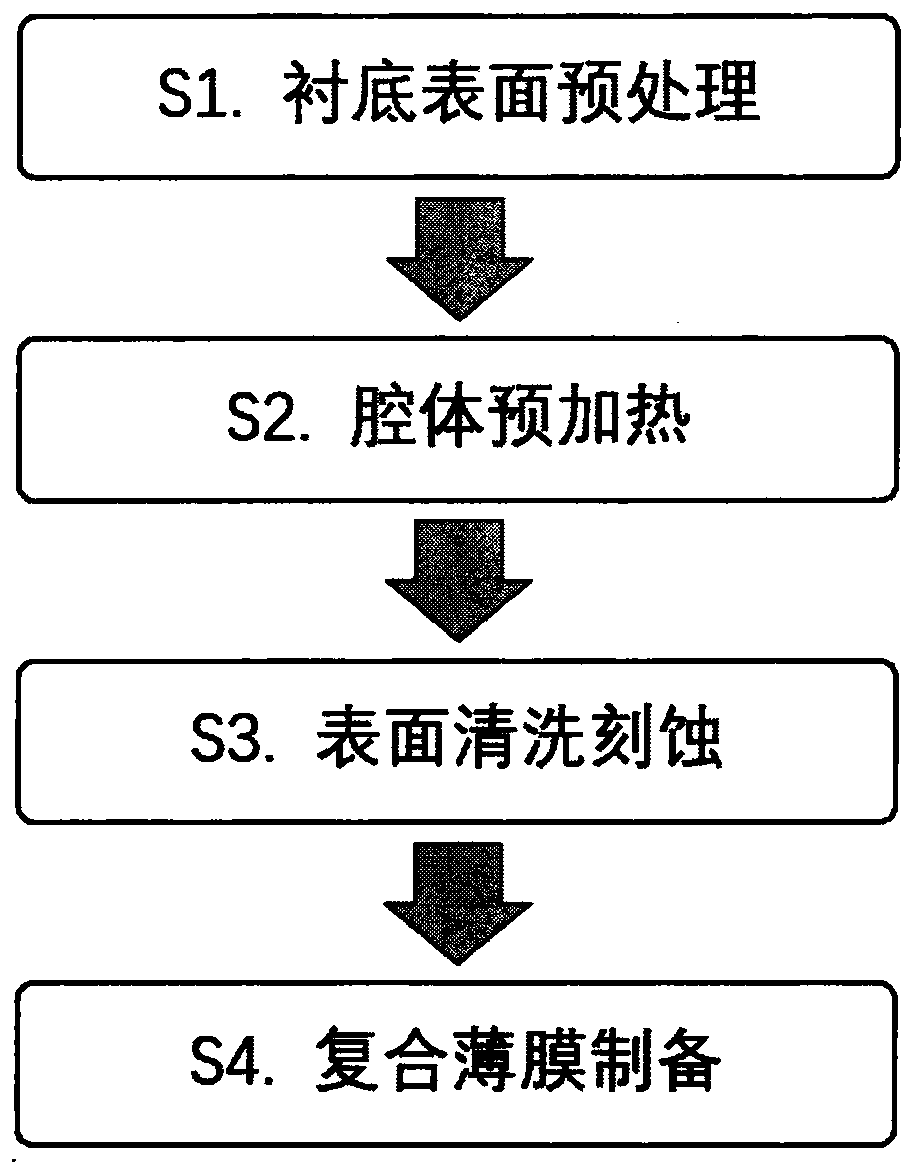

[0053] above ScB 2 -The preparation method of B superhard composite film, process such as figure 1 As shown, the specific steps are as follows:

[0054] Step 1: Substrate Surface Pretreatment

[0055] The substrate is selected as a silicon wafer whose surface is oxidized to silicon dioxide (abbreviated as an oxide wafer), and the substrate is placed in a container containing acetone, ethanol and deionized water in sequence for ultrasonic cleaning and drying to remove organic matter on the surface of the substrate. and particles and other impurities.

[0056] Step 2: Chamber Preheating

[0057] Put the pretreated oxide sheet into the magnetron sputtering apparatus, and vacuum until the vacuum reaches 1.0×10 -3 At Pa, heat the cavity to 400°C.

[0058] Step 3: Surface Cleaning and Etching

[0059] Vacuum first to maintain the vacuum degree in ...

Embodiment 2

[0064] A ScB 2 -B superhard composite film, the chemical formula is 0.65ScB e -0.35B superhard composite material composition.

[0065] above ScB 2 -The preparation method of composite thin film specifically comprises the following steps:

[0066] Step 1: Substrate Surface Pretreatment

[0067] The substrate is selected as a quartz plate, and the substrate is sequentially placed in a container containing acetone, ethanol and deionized water for ultrasonic cleaning and drying to remove impurities such as organic matter and particles on the surface of the substrate.

[0068] Step 2: Chamber Preheating

[0069] Put the pretreated quartz sheet into the magnetron sputtering apparatus, and vacuum until the vacuum reaches 5.0×10 -3 At Pa, heat the cavity to 470°C.

[0070] Step 3: Surface Cleaning and Etching

[0071] Vacuum first to maintain the vacuum degree in the magnetron sputtering apparatus at 5×10 -3 Pa, then feed argon gas into the magnetron sputtering apparatus to m...

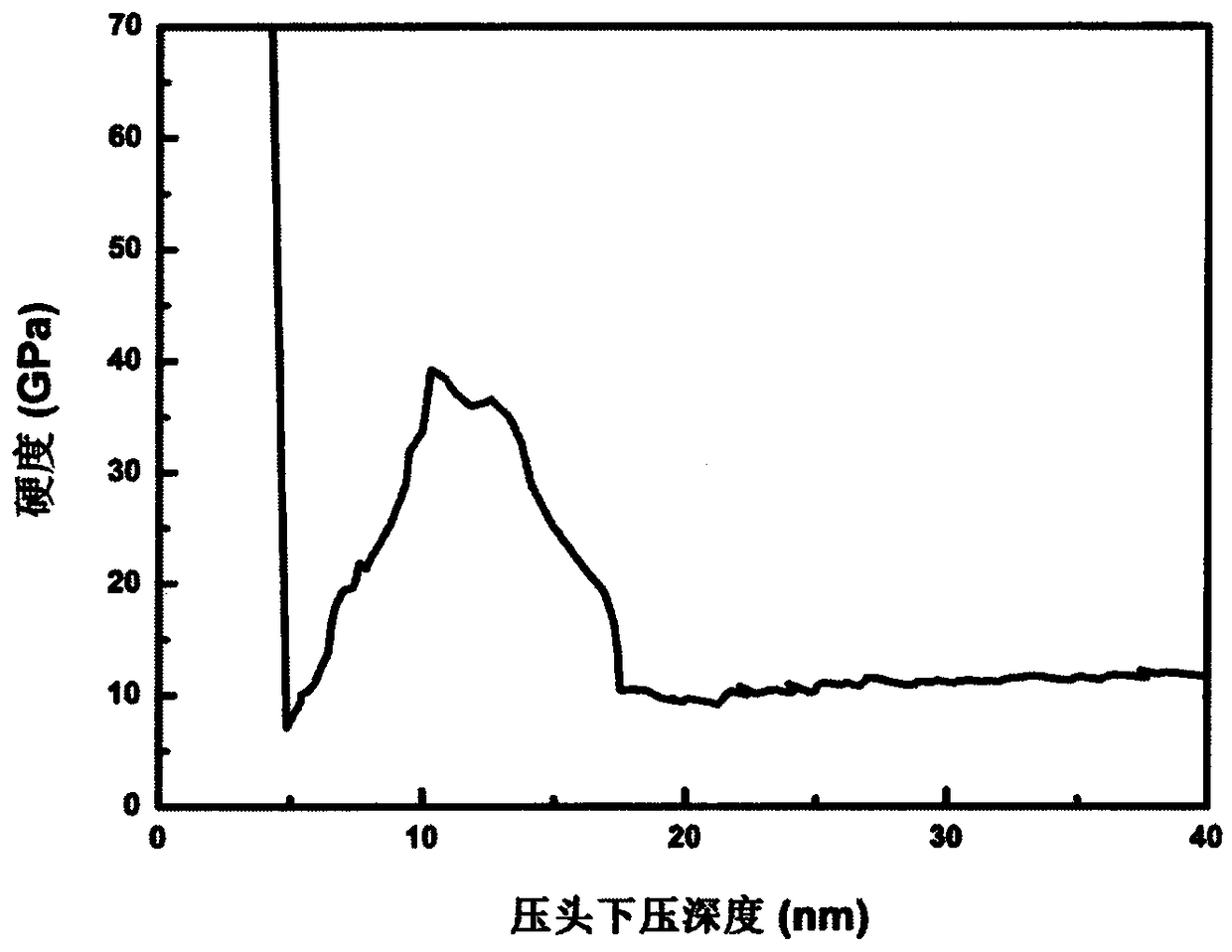

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com