Low-cost medium-strength titanium alloy material and preparation method thereof

A titanium alloy, low-cost technology, applied in the field of high-strength titanium alloy materials and its preparation, can solve the problems of increased manufacturing costs, restrictions on large-scale promotion and application, unfavorable promotion and use of titanium alloy materials in a wide range, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the above-mentioned low-cost medium-strength titanium alloy material comprises the following steps:

[0026] 1) According to the mass percentage of the components: Al: 3.0% ~ 5.5%, Fe: 0.4% ~ 2.0%, O: 0.06% ~ 0.50%, Si: 0.05% ~ 0.35%, the balance is titanium and unavoidable Impurities, wherein the weight percentage of impurities is: C: ≤0.05%, N: ≤0.03%, H: ≤0.015%, weighed and mixed, and pressed by a press to form an electrode block;

[0027] 2) Using ion welding or vacuum electron beam welding, the pressed electrode blocks are welded into strip electrodes; among them, the ion welding is vacuum plasma welding or argon shielded ion welding.

[0028] 3) Using the strip electrode prepared in step 2) as a consumable electrode to melt in a vacuum consumable electric arc furnace to obtain a primary ingot; wherein, the melting current is 5-23KA, and the melting voltage is 26-40V.

[0029] 4) Invert the primary ingot and use it as a consumable electr...

Embodiment 1

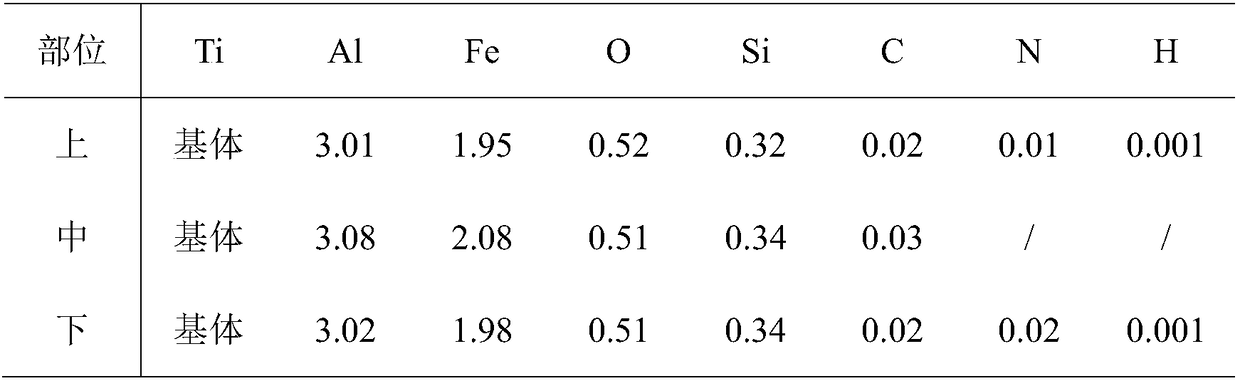

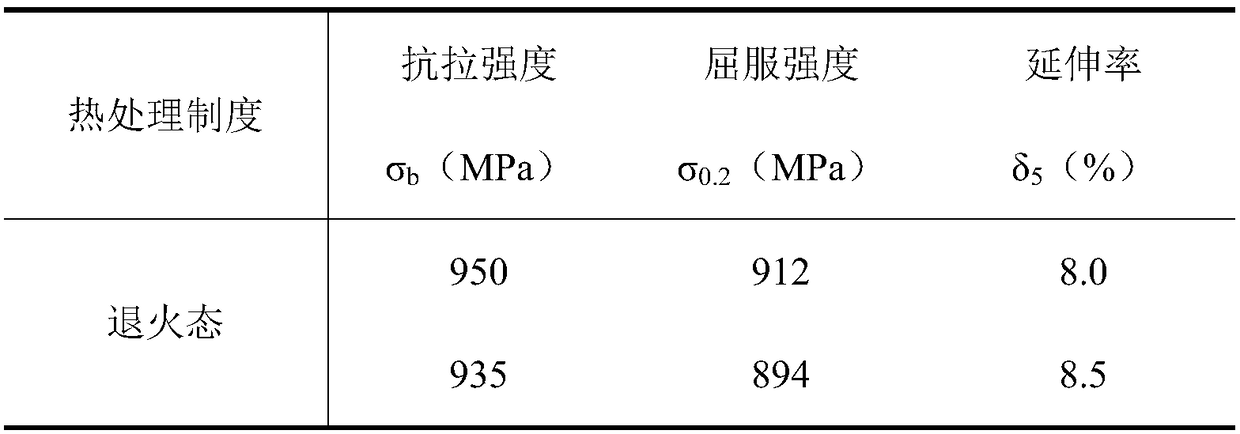

[0037] Preparation of 300Kg grade Ti-3.0Al-2.0Fe-0.5O-0.35Si alloy ingot and bar:

[0038] (1) Ingredients and electrode pressing:

[0039] Select first-grade sponge titanium, Fe chips, Al beans, titanium dioxide and titanium-silicon alloy, weigh and mix materials according to the above-mentioned composition ratio, and press them into block electrodes.

[0040] (2) Electrode preparation:

[0041] A vacuum plasma welding machine is used to weld the pressed electrode blocks into long strip electrodes.

[0042] (3) Prepare primary ingot

[0043] Use the electrode prepared in the previous step as the consumable electrode to melt in a vacuum consumable electric arc furnace to obtain a primary ingot, the melting current is 5-7KA, and the melting voltage is 26-32V.

[0044] (4) Preparation of ingot

[0045] The primary ingot is turned upside down and used as a consumable electrode for secondary melting in a vacuum consumable electric arc furnace to obtain a finished ingot. The me...

Embodiment 2

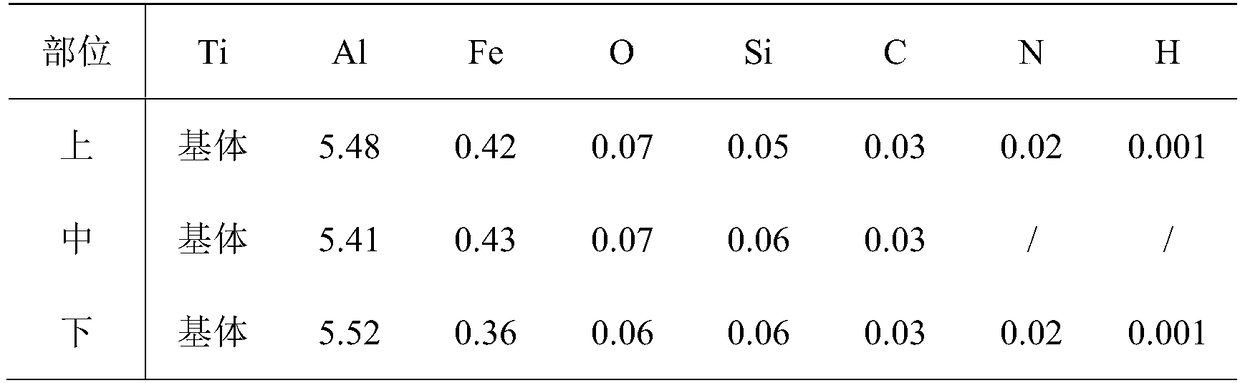

[0066] Preparation of 1000Kg grade Ti-5.5Al-0.4Fe-0.06O-0.05Si alloy ingot and its forging:

[0067] (1) Ingredients and electrode pressing:

[0068] Select first-grade sponge titanium, Fe chips, Al beans, titanium dioxide and titanium-silicon alloy, weigh and mix materials according to the above-mentioned composition ratio, and press them into block electrodes.

[0069] (2) Electrode preparation:

[0070] A vacuum plasma welding machine is used to weld the pressed electrode blocks into long strip electrodes.

[0071] (3) Prepare primary ingot

[0072] The electrode prepared in the previous step is used as the consumable electrode to melt in a vacuum consumable electric arc furnace to obtain a primary ingot, the melting current is 8-10KA, and the melting voltage is 26-32V.

[0073] (4) Preparation of ingot

[0074] The primary ingot is turned upside down and used as a consumable electrode for secondary melting in a vacuum consumable electric arc furnace to obtain a finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com