Method for preparing paint used for envelope material

A coating and capsule technology, used in polyamide coatings, epoxy resin coatings, coatings, etc., can solve the problem of inability to meet technical requirements for high-altitude navigation, poor compatibility of aramid fiber substrates, and high and low temperature resistance of coatings. Poor performance and other problems, to achieve the effect of improving interface compatibility, high strength uniformity, high and low temperature resistance and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

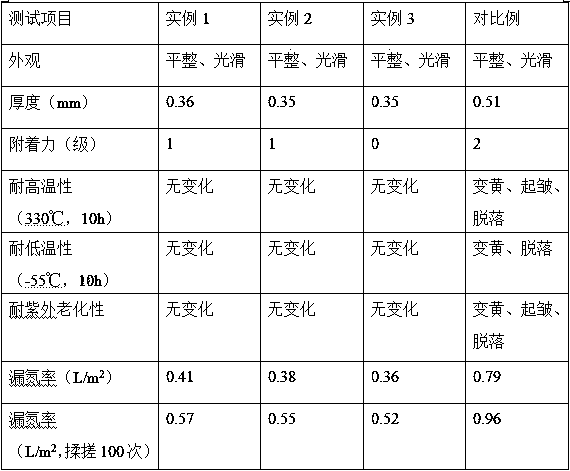

Examples

Embodiment Construction

[0024] Take 16-20g of 3-aminophenol, 10-12g of ethyl acetoacetate, 17-20g of zinc chloride and 70-80mL of absolute ethanol, put them in a three-necked flask with a stirrer and a reflux tube, and heat under nitrogen protection Raise the temperature to 70-80°C, start the stirrer to keep stirring at a speed of 400-450r / min, condense and reflux for 14-16 hours, and naturally cool to room temperature to obtain the reaction solution; add 60-80mL of 10% Hydrochloric acid, stirred and mixed for 10-15 minutes, filtered to remove the filtrate to obtain a solid product, washed the solid product with distilled water for 3-4 times, placed in an oven, heated to 60-70°C, dried for 8-9 hours, and obtained a dry product. Recrystallize the dried product with 70-75mL of isopropanol to obtain coumarin crystals; take 8-10g of coumarin crystals, 10-12g of 2,3-epoxypropyltrimethylammonium chloride and 40-50mL of mass Put hydrochloric acid with a fraction of 20% in a three-necked flask with a stirrer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com