Anti-aging antibacterial PE (Poly Ethylene) film and preparation method thereof

An anti-aging, thin-film technology, applied in the field of plastics, can solve the problems that PE film does not have bacteriostatic and anti-oxidation, migration, food safety hazards, etc., to achieve improved heat resistance and anti-oxidation performance, low cost, good ink The effect of adhesion and pigment adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

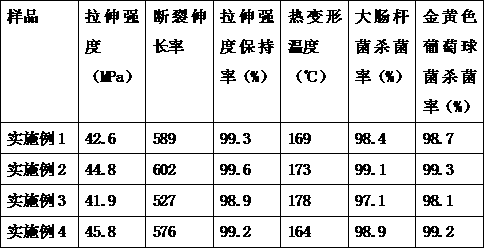

Examples

Embodiment 1

[0026] An aging-resistant and antibacterial PE film, its raw material composition and weight-to-number ratio are: 100 parts of PE resin, 20 parts of polyvinyl alcohol, 4 parts of shell powder, 6 parts of nano-calcium carbonate, 1.5 parts of silicon nitride fiber, and 1 part of phytic acid. 1.5 parts of octaphenyl clathrate silsesquioxane, 1 part of polyaminopropylmethyl silsesquioxane, 3 parts of carboxymethyl cellulose, 4 parts of processing aid, 1.0 part of compound antibacterial agent and 1010 Antioxidant 1.5 parts.

[0027] The composite antibacterial agent is composed of lanthanum oxide and chitosan with a mass ratio of 1:3.

[0028] The processing aid is composed of castor oil polyoxyethylene ether and maleic anhydride grafted polyethylene wax with a mass ratio of 1:3.

[0029] The preparation method of described aging-resistant antibacterial PE film, comprises the steps:

[0030] (1) Add phytic acid and octaphenyl clathrate silsesquioxane to PE resin, shell powder, na...

Embodiment 2

[0035] An aging-resistant and antibacterial PE film, its raw material composition and weight / number ratio are: 100 parts of PE resin, 25 parts of polyvinyl alcohol, 3 parts of shell powder, 8 parts of nano-calcium carbonate, 3 parts of silicon nitride fiber, 1.2 parts of phytic acid 1 part of octaphenyl clathrate silsesquioxane, 1.2 parts of polyaminopropylmethyl silsesquioxane, 4 parts of carboxymethyl cellulose, 3 parts of processing aid, 1.5 parts of compound antibacterial agent and 1076 Antioxidant 1 part.

[0036] The composite antibacterial agent is composed of lanthanum oxide and chitosan with a mass ratio of 1:4.

[0037] The processing aid is composed of castor oil polyoxyethylene ether and maleic anhydride grafted polyethylene wax with a mass ratio of 1:4.

[0038] The preparation method of described aging-resistant antibacterial PE film, comprises the steps:

[0039] (1) Add phytic acid and octaphenyl clathrate silsesquioxane to PE resin, shell powder, nano-calciu...

Embodiment 3

[0044] An aging-resistant and antibacterial PE film, its raw material composition and weight / number ratio are: 100 parts of PE resin, 30 parts of polyvinyl alcohol, 4 parts of shell powder, 5 parts of nano-calcium carbonate, 2.5 parts of silicon nitride fiber, 0.5 parts of phytic acid 2 parts of octaphenyl clathrate silsesquioxane, 1.5 parts of polyaminopropyl methyl silsesquioxane, 3 parts of carboxymethyl cellulose, 4 parts of processing aid, 0.5 part of compound antibacterial agent and CA Antioxidant 2 parts.

[0045] The composite antibacterial agent is composed of lanthanum oxide and chitosan with a mass ratio of 1:2.

[0046] The processing aid is composed of castor oil polyoxyethylene ether and maleic anhydride grafted polyethylene wax with a mass ratio of 1:3.

[0047] The preparation method of described aging-resistant antibacterial PE film, comprises the steps:

[0048] (1) Add phytic acid and octaphenyl clathrate silsesquioxane to PE resin, shell powder, nano-calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com