Ceramic membrane tube machining equipment

A ceramic membrane tube and processing equipment technology, which is applied in stone processing equipment, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as heavy workload, low efficiency, and easy product problems, and achieve heavy workload, The effect of small workload and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

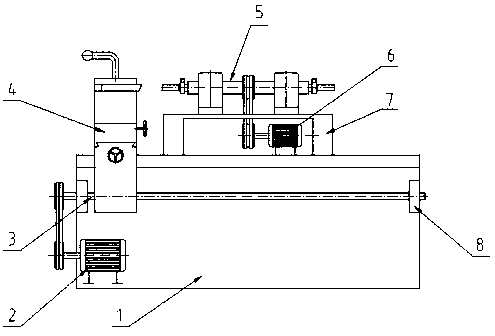

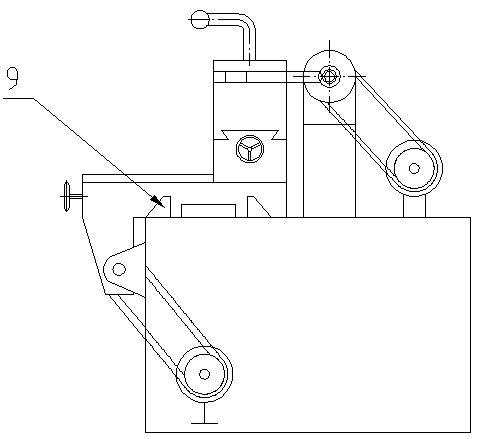

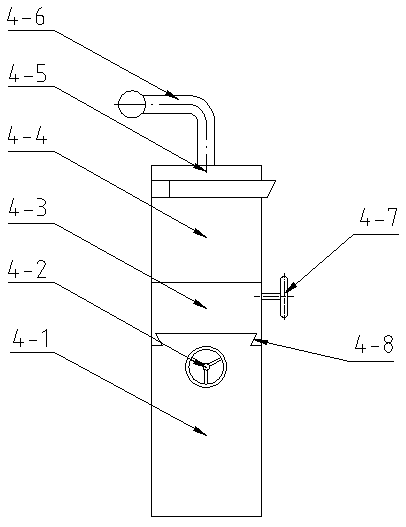

[0051] see Figure 1-12, in the figure, a ceramic membrane tube processing equipment, including a bed 1, a traveling mechanism 4, a spindle mechanism 5, a spindle holder 7, a drive motor 2, a spindle motor 6, a screw 3 and a screw bearing 8. A high-precision trapezoidal table guide rail 9 is set on the bed, and the traveling mechanism is set on the guide rail. There are screw holes 4-1-1 at the lower part of the traveling mechanism. Above; the spindle mechanism is fixed on the spindle fixing seat, and the spindle fixing seat is fixed on the bed, and the corresponding fixing method is bolt or welding; the screw and the driving motor, the spindle mechanism and the spindle motor are connected by a pulley and a belt, and the spindle motor is fixed by a bolt on the bed. The traveling mechanism includes a walking slider 4-1, a feed slider 4-3, a tool holder slider 4-4, a tool holder 4-5, a rotating handle 4-6, a feed handwheel 4-2 and a fine-tuning handwheel 4 -7. Set trapezoidal...

Embodiment 2

[0054] see Figure 13-14 , among the figure, grinder cutter 12 or grinder 13 are installed on the knife rest slide block. In this embodiment, a cutting machine or a grinding wheel can also be used to cut or grind the end of the ceramic membrane tube.

Embodiment 3

[0056] see Figure 15 , in the figure, the spindle motor 6 is fixed below the bed 1. This embodiment increases the aesthetics of the equipment on the one hand, and increases the safety on the other hand. At the same time, it prevents dust from eroding the motor shaft and protects the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com