A method of controlling non-metallic inclusions in powder metallurgy superalloy master alloy

A technology of non-metallic inclusions and superalloys, which is applied in the field of powder metallurgy superalloy preparation, can solve the problems of high vacuum degree and many inclusions, and achieve the effects of uniform distribution, low cost and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

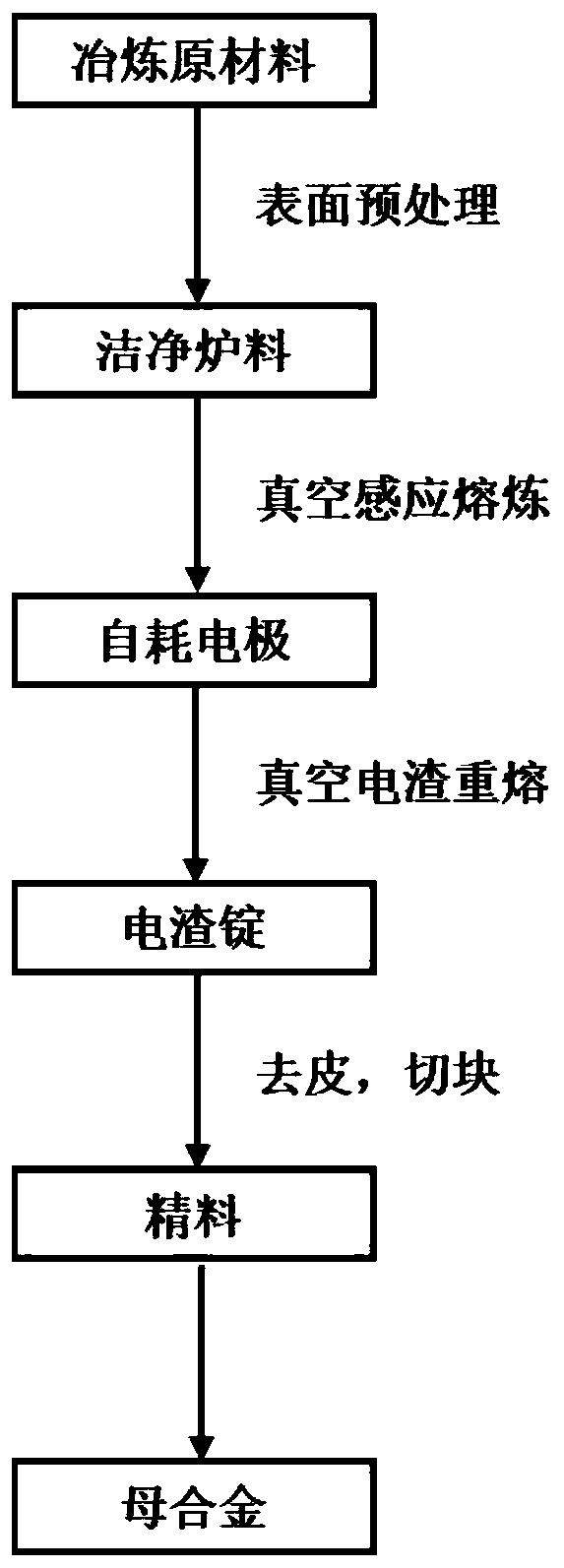

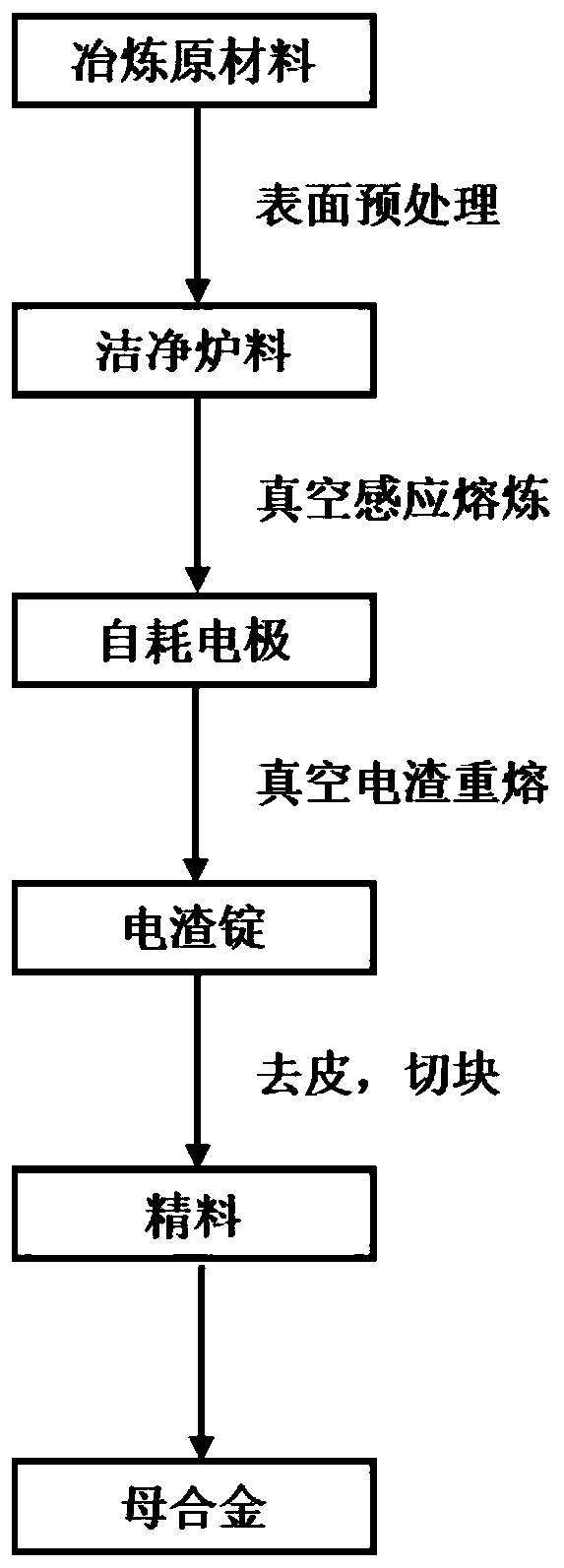

Method used

Image

Examples

Embodiment 1

[0021] Example 1: FGH4096 powder metallurgy superalloy master alloy

[0022] (1) Raw material surface pretreatment process: use block pure nickel, pure chromium, pure cobalt, pure tungsten, pure molybdenum, pure niobium, pure aluminum, pure titanium, high-purity graphite, boron, zirconium, etc. as raw materials, various raw materials The purity is greater than 99.9%; the metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides, and the pretreatment time is 30 minutes; then various metal raw materials are placed in absolute ethanol for ultrasonic treatment, and the treatment time is 15min.

[0023] (2) Vacuum induction melting process: first put Ni, Cr, Co, W, Mo, Fe, which have low affinity with O and N, into the crucible of the vacuum induction melting furnace; vacuumize to 5×10 -2 Pa, for smelting; after the melt is melted, add C and refine for 25 minutes; add strong nitride and oxide forming elements Nb, Ti, Al, and heat unti...

Embodiment 2

[0027] Example 2: FGH4096 powder metallurgy superalloy master alloy

[0028] (1) Raw material surface pretreatment process: use block pure nickel, pure chromium, pure cobalt, pure tungsten, pure molybdenum, pure niobium, pure aluminum, pure titanium, high-purity graphite, boron, zirconium, etc. as raw materials, various raw materials The purity is greater than 99.9%; the metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides, and the pretreatment time is 30 minutes; then various metal raw materials are placed in absolute ethanol for ultrasonic treatment, and the treatment time is 15min.

[0029] (2) Vacuum induction melting process: first put Ni, Cr, Co, W, Mo, Fe, which have low affinity with O and N, into the crucible of the vacuum induction melting furnace; vacuumize to 5×10 -2 Pa, for smelting; after the melt is melted, add C and refine for 25 minutes; add strong nitride and oxide forming elements Nb, Ti, Al, and heat unti...

Embodiment 3

[0033] Embodiment 3: FGH4097 powder metallurgy superalloy master alloy

[0034] (1) Raw material surface pretreatment process: use block pure nickel, pure chromium, pure cobalt, pure tungsten, pure molybdenum, pure niobium, pure aluminum, pure titanium, high-purity graphite, boron, zirconium, etc. as raw materials, various raw materials The purity is greater than 99.9%; the metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides, and the pretreatment time is 30 minutes; then various metal raw materials are placed in absolute ethanol for ultrasonic treatment, and the treatment time is 15min.

[0035] (2) Vacuum induction melting process: first put Ni, Cr, Co, W, Mo, Fe, which have low affinity with O and N, into the crucible of the vacuum induction melting furnace; vacuumize to 5×10 -2 Pa, for smelting; after the melt is melted, add C and refine for 25 minutes; add strong nitride and oxide forming elements Nb, Ti, Al, and heat u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com