Preparation method of high-strength anti-bacteria bone fracture plate

A bone plate, high-strength technology, applied in the field of preparation of high-strength antibacterial bone plate, can solve the problems of bacterial infection, low strength, etc., and achieve the effect of improving plastic toughness, good compatibility, and good mutual wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

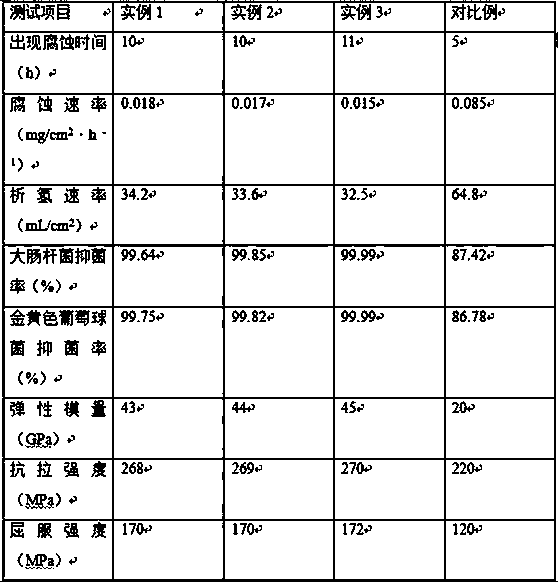

Examples

example 1

[0027] In parts by weight, take 80 parts of calcium hydrogen phosphate and 30 parts of calcium carbonate, mix and stir for 10 minutes, place them in a mortar and grind for 45 minutes, pass through a 200-mesh sieve to obtain sifted mixed calcium powder, and place the sifted mixed calcium powder in a resistance furnace In the process, electrify and heat up to 930°C at a rate of 10°C / min, keep the temperature for 4 hours, and cool down to room temperature naturally to obtain calcium phosphate powder; take the above calcium phosphate powder out of the resistance furnace, grind for 30 minutes, and pass through a 200-mesh sieve To obtain sieved calcium phosphate powder, place the sieved calcium phosphate powder in a resistance furnace, heat up to 1000°C through a power program, heat-preserve and sinter for 3 hours, and cool naturally to room temperature to obtain lightly burned calcium powder; take one end of the pure magnesium sample and drill a hole, Use sandpaper to roughly grind ...

example 2

[0029] In parts by weight, take 85 parts of calcium hydrogen phosphate and 35 parts of calcium carbonate, mix and stir for 12 minutes, place them in a mortar and grind for 50 minutes, pass through a 200-mesh sieve to obtain sifted mixed calcium powder, and place the sifted mixed calcium powder in a resistance furnace In the process, electrify and heat up to 945°C at a rate of 12°C / min, hold the temperature for 4.5 hours, and naturally cool to room temperature to obtain calcium phosphate powder; take the above calcium phosphate powder out of the resistance furnace, grind for 32 minutes, and pass through 200 mesh Sieve the sieved calcium phosphate powder, place the sieved calcium phosphate powder in a resistance furnace, heat up to 1020°C with a power program, heat-preserve and sinter for 3.5 hours, and naturally cool to room temperature to obtain lightly burned calcium powder; take one end of the pure magnesium sample to drill hole, use sandpaper to roughly grind the surface of ...

example 3

[0031] In parts by weight, take 90 parts of calcium hydrogen phosphate and 40 parts of calcium carbonate, mix and stir for 15 minutes, place them in a mortar and grind for 55 minutes, pass through a 200-mesh sieve to obtain sifted mixed calcium powder, and place the sifted mixed calcium powder in a resistance furnace In the process, electrify and heat up to 960°C at a rate of 15°C / min, keep the temperature for 5 hours, and cool down to room temperature naturally to obtain calcium phosphate powder; take the above calcium phosphate powder out of the resistance furnace, grind for 35 minutes, and pass through a 200-mesh sieve To obtain sieved calcium phosphate powder, place the sieved calcium phosphate powder in a resistance furnace, heat up to 1050°C in a power program, heat-preserve and sinter for 4 hours, and cool naturally to room temperature to obtain lightly burned calcium powder; take one end of the pure magnesium sample and drill a hole, Use sandpaper to roughly grind the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com