Polyformaldehyde and polyurethane blend cable sheath material

A technology of cable sheath material and polyurethane, which is applied in the field of cable sheath material, can solve the problems of high notch sensitivity and insufficient toughness, and achieve the effects of environmental friendliness, improved mechanical properties and increased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

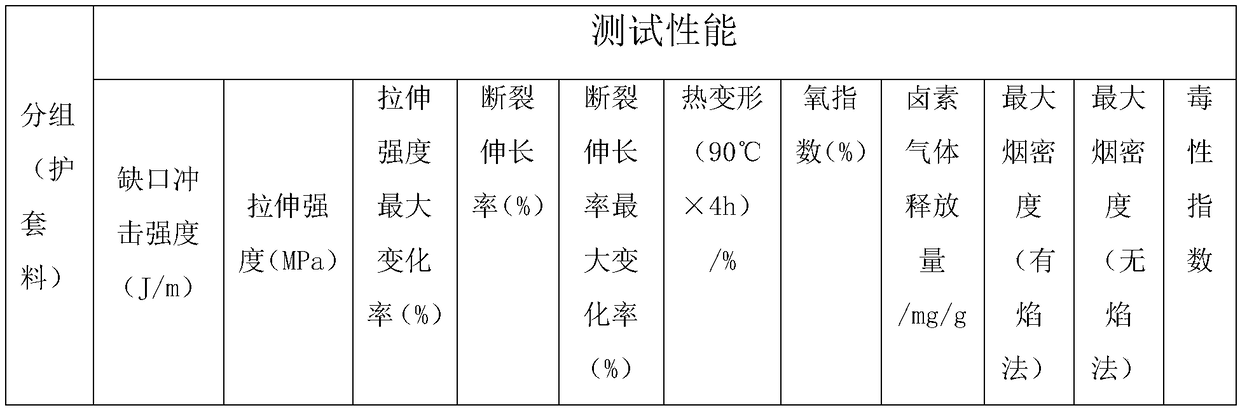

Image

Examples

Embodiment 1

[0038] A polyoxymethylene-polyurethane blend cable sheath material A, whose raw materials are composed of the following components by weight: 55 parts of polyoxymethylene, 20 parts of polyurethane, 7 parts of polyurethane elastomer, 0.2 parts of melamine compatibilizer, 2 parts of red phosphorus 1 part, 1 part of attapulgite (ATP) and 2 parts of expandable graphite.

[0039] The weight average molecular weight of the polyoxymethylene is 150000g / mol; the polyurethane is the reaction product of 1,4-butanediol and isocyanurate, and the NCO content is 50% by weight; the polyurethane elastomer is polyethanol and isocyanurate The reaction product has an NCO content of 45% by weight.

[0040] The preparation method of described sheath material, comprises the following steps:

[0041] 1) Add polyoxymethylene, polyurethane, polyurethane elastomer and melamine compatibilizer into a high-speed kneader and knead at 100°C for 20 minutes to obtain a mixed resin base material.

[0042] 2) ...

Embodiment 2

[0045] A polyoxymethylene-polyurethane blend cable sheath material B, whose raw materials are composed of the following components in parts by weight: 65 parts of polyoxymethylene, 25 parts of polyurethane, 8 parts of polyurethane elastomer, 0.4 parts of melamine compatibilizer, 4 parts of red phosphorus 2 parts, 2 parts of attapulgite (ATP) and 5 parts of expandable graphite.

[0046] It is prepared according to the preparation method of Example 1.

Embodiment 3

[0048] A polyoxymethylene-polyurethane blend cable sheath material C, whose raw materials are composed of the following components by weight: 58 parts of polyoxymethylene, 23 parts of polyurethane, 7.5 parts of polyurethane elastomer, 0.3 parts of melamine compatibilizer, 3 parts of red phosphorus parts, attapulgite (ATP) 1.5 parts and expandable graphite 3.5 parts.

[0049] It is prepared according to the preparation method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com