Method for producing liquid paraffin by using waste animal and vegetable oil

A technology for animal and vegetable oils and liquid paraffin, which is applied in the refining of petroleum wax, chemical instruments and methods, chemical/physical processes, etc., and can solve the problems of difficult removal of aromatic hydrocarbon impurities, unfavorable sustainable development of resources, and complicated refining processes. , to achieve the effect of low cost, reducing table pollution and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

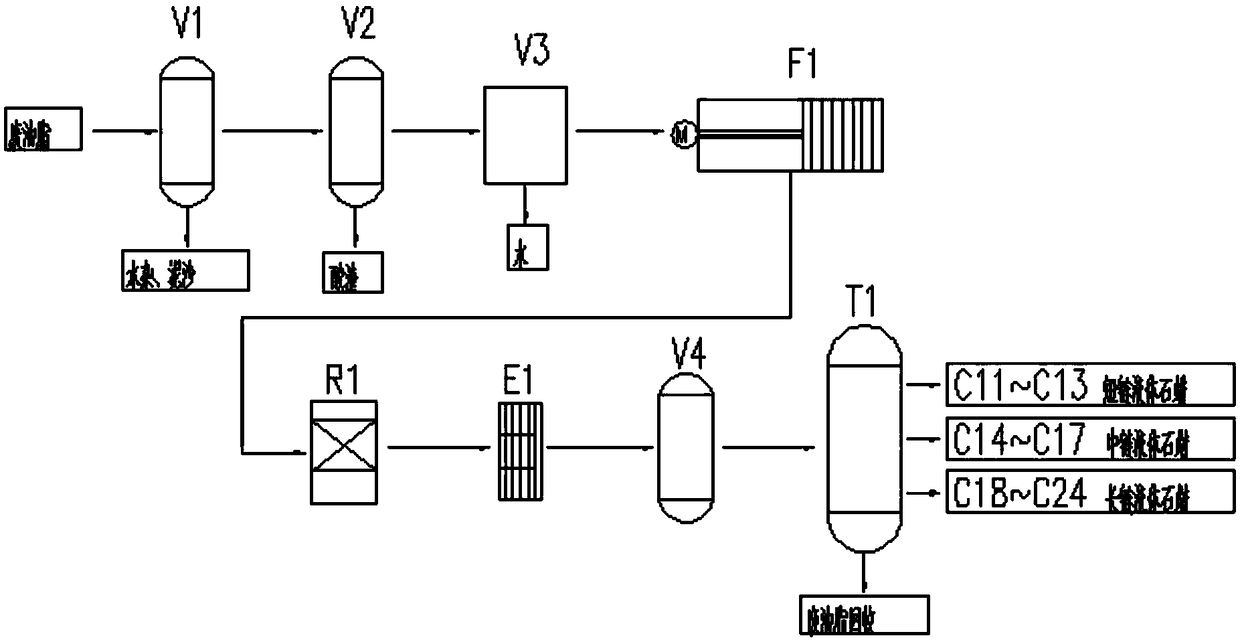

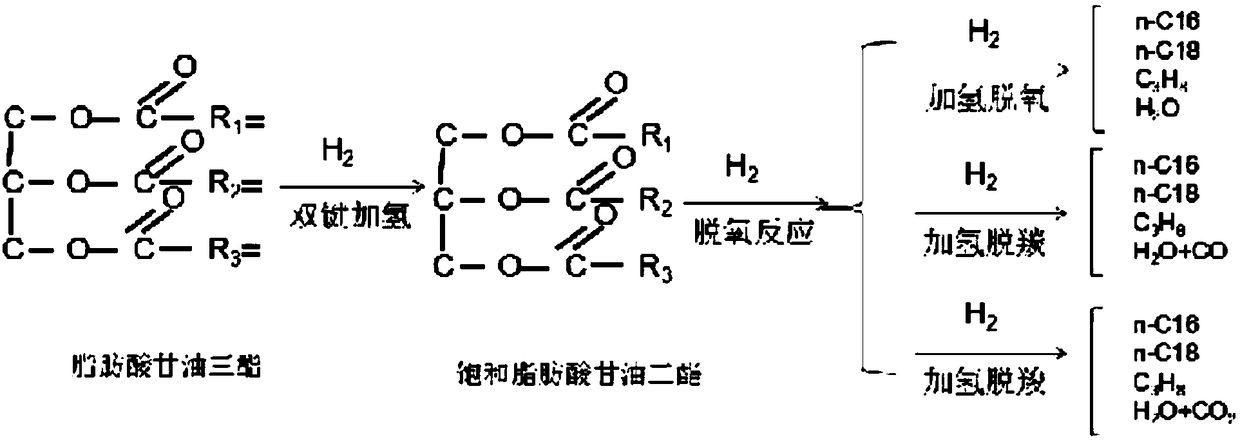

Method used

Image

Examples

preparation example Construction

[0021] 2. Preparation of catalyst: Ni-Mo-Co / Al was prepared by supersaturated impregnation method 3 o 2 Supported catalyst: (1) prepare ammonium molybdate aqueous solution and nickel nitrate aqueous solution with deionized water respectively, nickel nitrate solution is mixed dropwise in the ammonium molybdate solution, add ammonia water to be mixed with blue transparent dipping solution simultaneously; (2 ) Al with a particle size of 40-60 mesh after drying 3 o 2 The carrier is supersaturated and impregnated in Ni-Mo impregnation solution for 12 hours, dried in a vacuum oven at 120°C for 8 hours, and then placed in a muffle furnace for calcination at 500°C for 4 hours; (3) The calcined material is immersed in an aqueous solution of cobalt nitrate for 12 hours again, Repeat the above drying and calcination steps to get Ni-Mo-Co / Al 3 o 2 Supported catalyst, the relevant component content is Ni 10-20%, Mo 40-50%, Co 30-40% by molar ratio, and the total load is 15-20% accordin...

Embodiment 1

[0025] (1) The waste animal and vegetable oil raw material that adopts is gutter oil, physicochemical index: acid value 110.6mgKOH / g, iodine value 85.6gI 2 / 100g, saponification value 198.4mgKOH / g, water impurity mass fraction 2.61%, pH 5-6.

[0026] Waste oil pretreatment: Heat the waste oil to 90°C and let it stand for 12 hours to keep warm and settle, and discharge impurities such as bottom sediment, water and some flocculent organic suspended matter; then add 0.5% of 50% concentrated sulfuric acid to the material and react at 90°C for 0.5 h, let it settle for 1 hour to discharge the acid slag, add 10% NaHCO to the waste oil after the acidification treatment 3 The solution was neutralized to neutral, and the moisture brought by neutralization was removed; finally, 4% activated clay and 1% diatomaceous earth were added to the waste oil, stirred at 90°C for 1 hour, and then filtered to obtain a clear and transparent waste oil Oil.

[0027] (2) Preparation of hydrodeoxygenati...

Embodiment 2

[0033] (1) raw material is hogwash oil, physical and chemical index: acid value 9.6mgKOH / g, iodine value 82.1gI 2 / 100g, saponification value 199.8mgKOH / g, water impurity mass fraction 1.58%, pH 5-6.

[0034] (2) The raw material oil pretreatment, catalyst preparation, sulfidation and hydrogenation reduction are the same as in Example 1.

[0035] (3) The reaction conditions are the same as in Example 1.

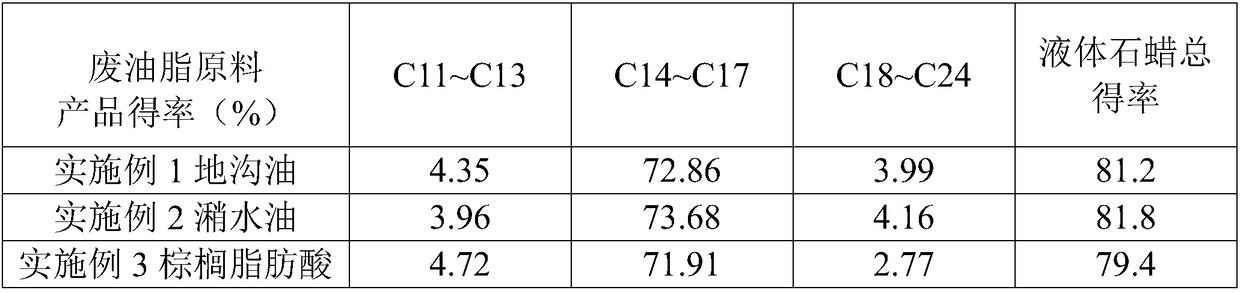

[0036] (4) Reaction result: the conversion rate of hogwash oil is 99.99%, basically completely converted. Obtain colorless and transparent liquid paraffin, the chromatographic analysis of liquid paraffin distribution is shown in Table 1.

[0037] (5) After continuous reaction for 600 hours, the catalytic activity did not decrease, and the conversion rate was still 99.99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com