Aluminum alloy workpiece additive manufacturing method implemented through friction stir welding

A technology of friction stir welding and additive manufacturing, applied in the field of additive manufacturing, which can solve problems such as limitations, low laser absorption rate, increased cost of additive manufacturing and process complexity, etc., to achieve increased strength, enhanced mechanical properties, and elimination of internal The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

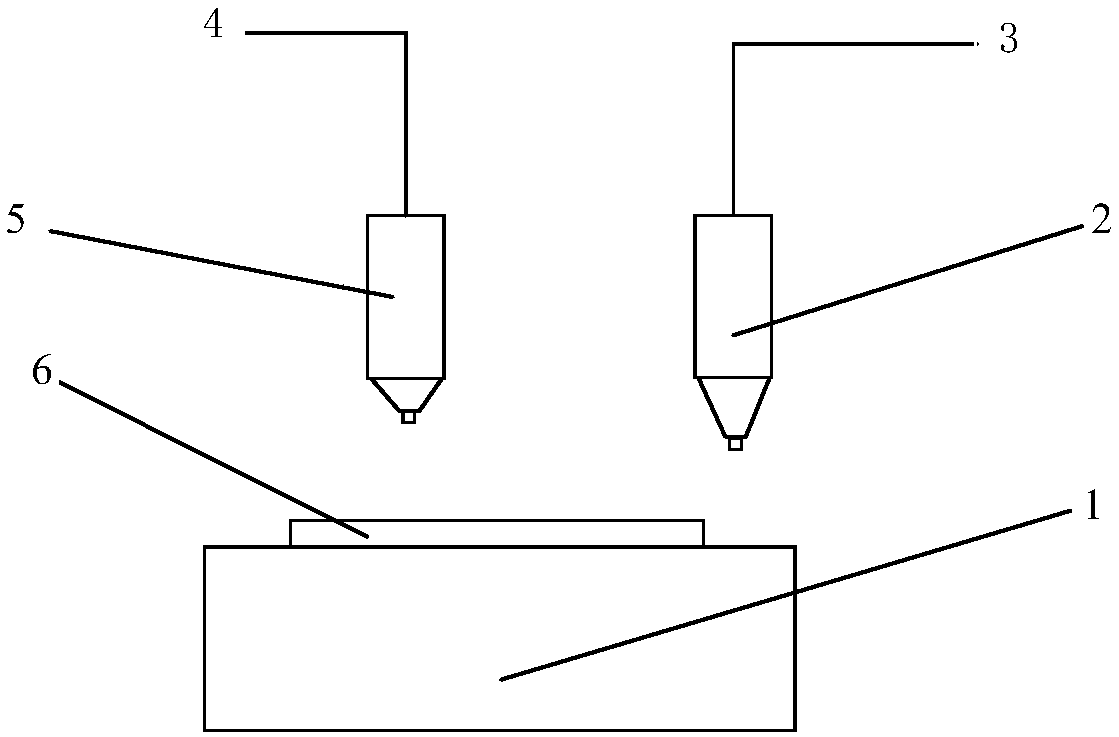

Image

Examples

Embodiment 1

[0035] (1) Fix the aluminum alloy substrate on the workbench, remove the surface oxide scale with an angle grinder, and clean the surface oil residue with alcohol.

[0036] (2) Use the slicing software to establish the CAD model of the target workpiece and perform slicing. The thickness of the slicing is 2.0mm, and then plan the forming path of the workpiece, and import the production path program file into the control system.

[0037] (3) The aluminum alloy welding wire with a diameter of 1.2mm is used as the raw material, and the welding gun is used to build the layer according to the set procedure. Each layer is manufactured by welding one by one during manufacturing. The specific process parameters during welding are set as: wire feeding The speed is 6m / min, the welding speed is 0.5m / min, the shielding gas flow is 20L / min, the shielding gas used is inert gas, and the purity of the inert gas is not less than 99.99%; after the layer is formed, wait for 60s, and mill the layer Tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com