A kind of preparation method of yal1-x Fe xO3 nanometer pigment

A nano-pigment and doped technology, applied in fibrous fillers and other directions, can solve the problems of cumbersome preparation steps, difficult to ensure quality in large-scale production, etc., and achieve the effects of simple and controllable process, good crystal shape and low synthesis temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

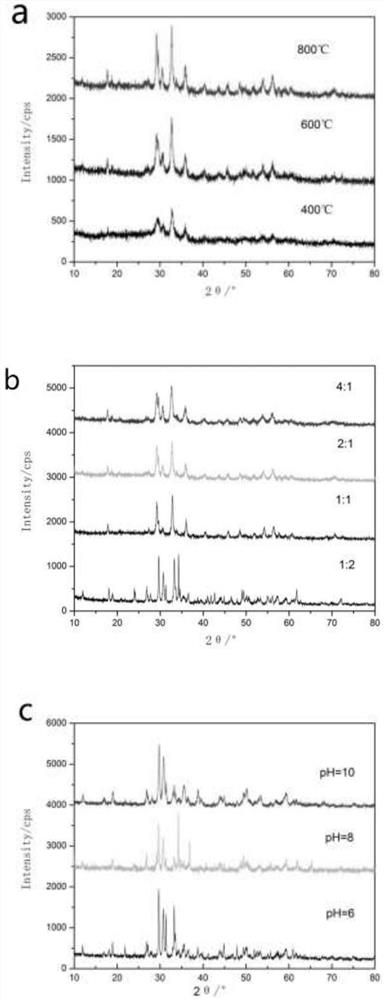

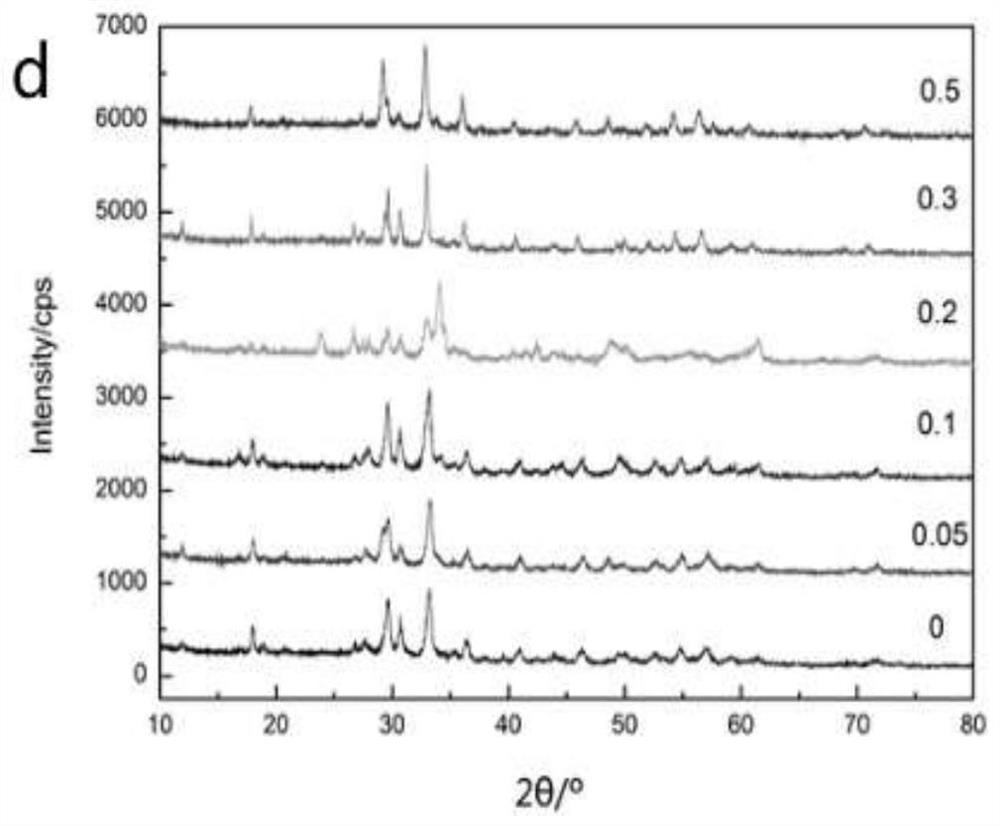

[0045] A kind of preparation method of doped nano pigment, doping YAlO with Fe 3 Nanocrystalline, prepared with 0.1mol of YAl 0.5 Fe 0.5 o 3 For example, include the following steps:

[0046] 1) At room temperature, take 100ml of deionized water and stir on a magnetic stirrer, dissolve 12.09 grams of ferric nitrate, 18.76 grams of aluminum nitrate, and 38.31 grams of yttrium nitrate in deionized water in turn, and add 0.6g of succinic acid is used as a stabilizer to obtain solution A;

[0047] 2) After the substances in the mixed solution A are completely dissolved, adjust the pH value of the solution A to 6 by dropping ammonia water to obtain the solution B, and then add 1,2 - Propylene Glycol; Obtain mixed solution;

[0048] 3) Stir the mixed solution obtained in step 2) on a constant temperature magnetic stirrer at 60°C for 2h until the solution turns into a gel, then dry, grind, and calcinate at 600°C for 4h to obtain solid YAl 0.5 Fe 0.5 o 3 Nano pigment powder. ...

Embodiment 2

[0050] A kind of preparation method of doped nano pigment, doping YAlO with Fe 3 Nanocrystalline, prepared with 0.1mol of YAl 0.5 Fe 0.5 o 3 For example, include the following steps:

[0051] 1) At room temperature, take 100ml of deionized water and stir on a magnetic stirrer, dissolve 12.09 grams of ferric nitrate, 18.76 grams of aluminum nitrate, and 38.31 grams of yttrium nitrate in deionized water in turn, and add 0.6g succinic acid is used as a stabilizer to obtain solution A;

[0052] 2) After the substances in the mixed solution A are completely dissolved, adjust the pH value of the solution A to 8 by dropping ammonia water to obtain the solution B, and then add 1,2 -Propylene Glycol, obtain mixed solution;

[0053] 3) Stir the mixed solution obtained in step 2) on a constant temperature magnetic stirrer at 60°C for 2h until the solution turns into a gel, then dry, grind, and calcinate at 600°C for 4h to obtain solid YAl 0.5 Fe 0.5 o 3 Nano pigment powder.

Embodiment 3

[0055] A kind of preparation method of doped nano pigment, doping YAlO with Fe 3 Nanocrystalline, prepared with 0.1mol of YAl 0.5 Fe 0.5 o 3 For example, include the following steps:

[0056] 1) At room temperature, take 100ml of deionized water and stir on a magnetic stirrer, dissolve 12.09 grams of ferric nitrate, 18.76 grams of aluminum nitrate, and 38.31 grams of yttrium nitrate in deionized water in turn, and add 0.6g succinic acid is used as a stabilizer to obtain solution A;

[0057] 2) After the substances in the mixed solution A are completely dissolved, adjust the pH value of the solution A to 10 by dropping ammonia water to obtain the solution B, and then add 1,2 -Propylene Glycol, obtain mixed solution;

[0058] 3) Stir the mixed solution obtained in step 2) on a 60°C constant temperature magnetic stirrer for 2h until the solution turns into a gel, then dry, grind, and calcinate at 600°C for 4 hours to obtain solid YAl 0.5 Fe 0.5 o 3 Nano pigment powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com