A kind of multi-core hollow energetic microspheres for emulsion explosives and preparation method thereof

A technology of emulsion explosives and microspheres, which is used in explosives processing equipment, explosives, non-explosive/non-thermal agent components, etc., can solve the problems of different sizes of hydrogen bubbles, failure of coating effect, easy to cause safety accidents, etc. Wide range of sources, simple preparation process, and the effect of increasing the charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

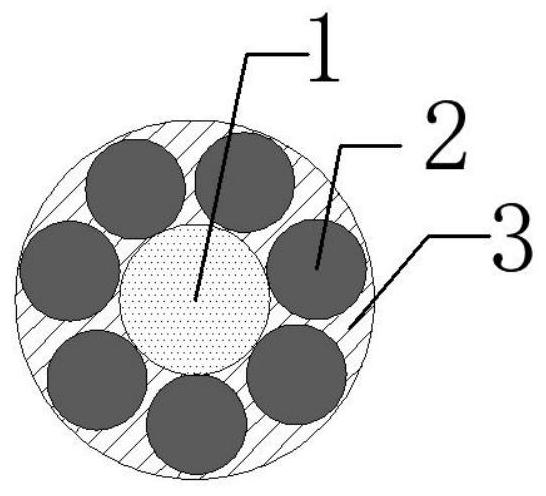

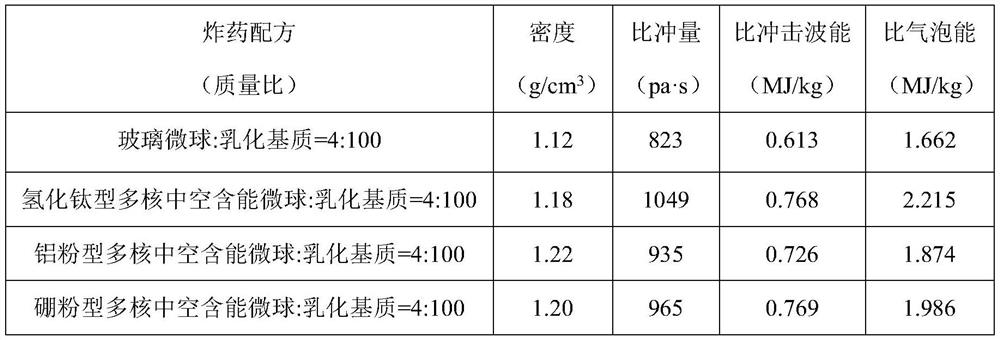

[0035] Titanium hydride type multi-core hollow energetic microspheres: the multi-core hollow energetic microspheres are mainly composed of the following components in parts by weight: 40 parts of methyl methacrylate monomer, 20 parts of expansion agent pentane, energetic additive TiH 2 40 parts of powder.

[0036] The preparation method of the multi-core hollow energetic microspheres for the emulsion explosive, the specific steps are as follows:

[0037] St1: Mix and dissolve 40 parts of methyl methacrylate, 0.8 parts of azobisisobutyronitrile, 0.08 parts of polyethylene glycol 200 dimethacrylate and 20 parts of pentane to form an oil phase, and then add 40 parts Parts of TiH 2 Powder, stir well to make the energetic additive and oil phase mix evenly.

[0038]St2: In 90 parts of deionized water, add 9 parts of nano-magnesium hydroxide and 1 part of 1% aqueous solution of sodium lauryl sulfate and mix evenly, and use it as a water phase dispersion medium.

[0039] St3: Add t...

Embodiment 2

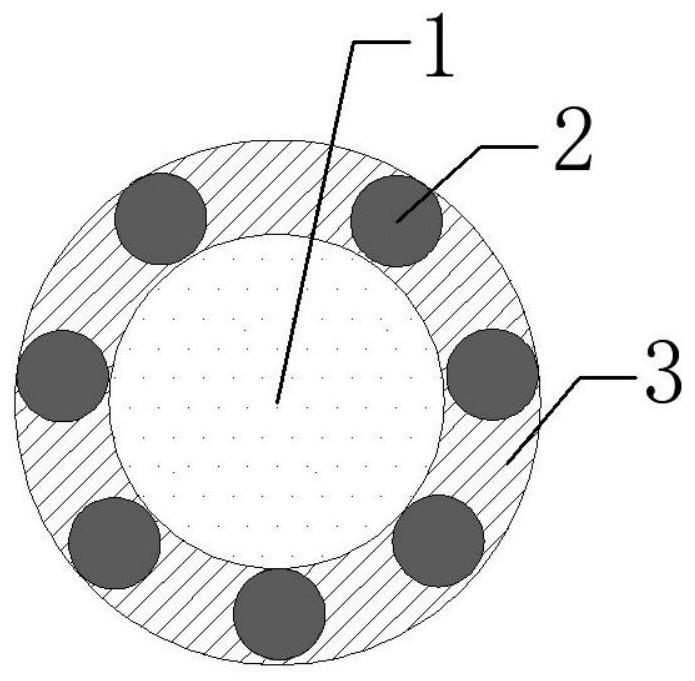

[0042] Aluminum powder type multi-core hollow energetic microspheres: the multi-core hollow energetic microspheres are mainly composed of the following components in parts by weight: 30 parts of acrylonitrile monomer, 10 parts of expansion agent octane, 60 parts of energetic additive aluminum powder .

[0043] The preparation method of the multi-core hollow energetic microspheres for the emulsion explosive, the specific steps are as follows:

[0044] St1: Mix and dissolve 30 parts of acrylonitrile, 0.7 parts of dibenzoyl peroxide, 0.2 parts of trimethylolpropane trimethacrylate and 10 parts of octane to form an oil phase, and then add 60 parts of Energy additive aluminum powder, fully stirred, so that the energy additive and the oil phase are evenly mixed.

[0045] St2: In 95 parts of deionized water, add 5 parts of polyvinyl alcohol and mix evenly, and use it as the water phase dispersion medium.

[0046] St3: Add the mixed oil phase prepared by St1 to the aqueous phase dis...

Embodiment 3

[0049] Boron powder type multi-core hollow energetic microspheres: the multi-core hollow energetic microspheres are mainly composed of the following components in parts by weight: 40 parts of acrylamide monomers, 20 parts of decane as an expansion agent, and 40 parts of boron powder as an energetic additive share.

[0050] The preparation method of the multi-core hollow energetic microspheres for the emulsion explosive, the specific steps are as follows:

[0051] St1: Mix and dissolve 40 parts of acrylamide monomer, 0.9 parts of benzoyl peroxide, 0.15 parts of dicumyl peroxide and 20 parts of decane to form an oil phase, and then add 40 parts of boron powder, Stir fully to make the energetic additive boron powder and the oil phase mix evenly.

[0052] St2: In 90 parts of deionized water, add 8 parts of nano silicon dioxide and 2 parts of 1% aqueous solution of dioctyl sodium sulfosuccinate and mix evenly, and use it as the aqueous phase dispersion medium.

[0053] St3: Add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com