Low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application

A technology of water treatment film and potting glue, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of high brittleness of epoxy resin, failure to achieve flexible packaging, and harsh use conditions, etc., and achieve excellent Adhesiveness, excellent protection performance, effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

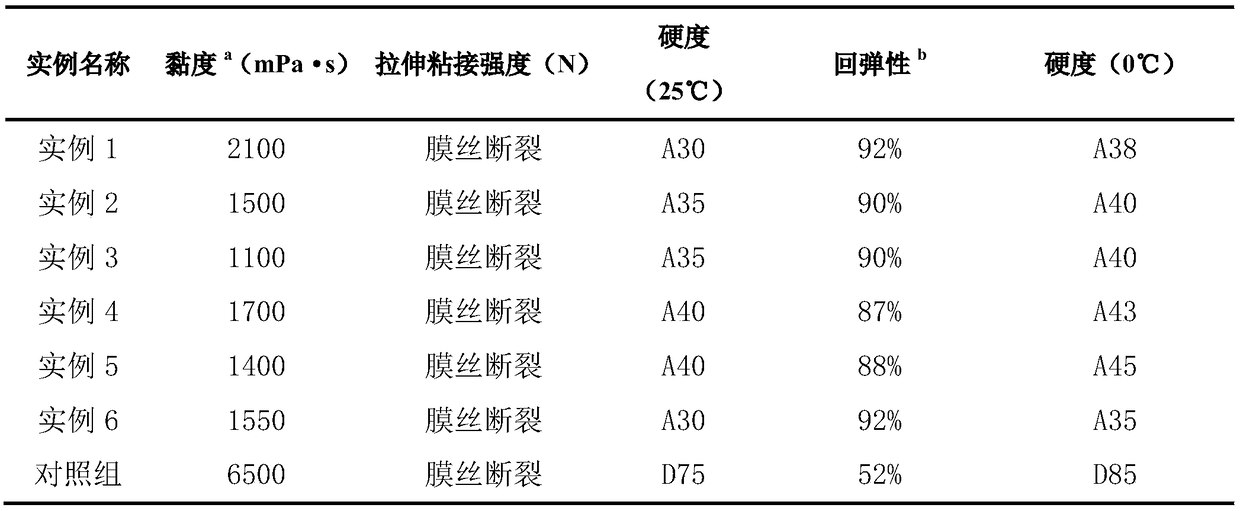

Examples

Embodiment 1

[0045] 70 parts by weight of E-51, 8 parts by weight of butyl glycidyl ether, 10 parts by weight of epoxy-terminated polyurethane, 9.9 parts by weight of talc, 0.1 parts by weight of KH-550, 2 parts by weight of polyoxygen Ethylene polyoxypropylene pentaerythritol ether was mixed and stirred evenly to obtain component A; 50 parts by weight of polyetheramine D400, 40 parts by weight of Baxxodur EC252, 10 parts by weight of 2,4,6-tris(dimethylaminomethyl) Mix phenol with light and stir component B; mix component A and component B at a weight ratio of 100:50 and stir evenly to obtain a low-hardness and high-elasticity epoxy potting glue.

Embodiment 2

[0047]50 parts by weight of E-51, 10 parts by weight of benzyl glycidyl ether, 10 parts by weight of o-cresyl glycidyl ether, 20 parts by weight of epoxy-terminated polyurethane, 6.9 parts by weight of titanium dioxide, 3 parts by weight of KH-570, 0.1 parts by weight of glycerol polyether stearic acid triester were mixed and stirred evenly to obtain component A; 20 parts by weight of Baxxodur EC310, 70 parts by weight of Baxxodur EC210, 10 parts by weight of 2,4,6- Mix tri(dimethylaminomethyl)phenol with light and stir component B; mix and stir components A and B at a weight ratio of 100:20 to obtain a low-hardness and high-elasticity epoxy potting glue.

Embodiment 3

[0049] 30 parts by weight of E-44, 10 parts by weight of 1,4-butanediol diglycidyl ether, 8 parts by weight of ethylene glycol diglycidyl ether, 20 parts by weight of epoxy-terminated polyethylene glycol, 30 parts by weight of fumed silica, 1 part by weight of KH-560, and 1 part by weight of nonylphenol polyoxyethylene ether were mixed and stirred evenly to obtain component A; 40 parts by weight of D2000, 45 parts by weight of TAC-900 , 10 parts by weight of 2,4,6-tris-2-ethylhexanoate of 6-tris(dimethylaminomethyl)phenol, 5 parts by weight of salicylic acid mixed with light and stirring component B; group A Part and B component are mixed and stirred evenly at a weight ratio of 100:10 to obtain a low-hardness and high-elasticity epoxy potting glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com