An ultrathin white covering film and an LED substrate using the white covering film

A technology for LED substrates and cover films, applied in lamination, printed circuits, electrical components, etc., can solve the problems of poor high temperature yellowing resistance of white ink cover films, reduce downstream processes, uneven printing thickness, etc., and improve operability , good weather resistance, the effect of preventing surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

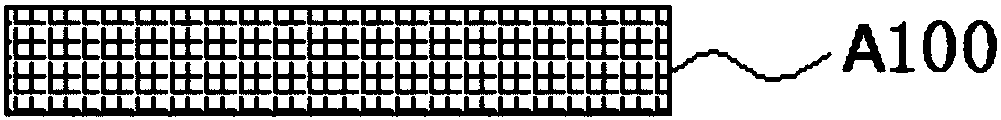

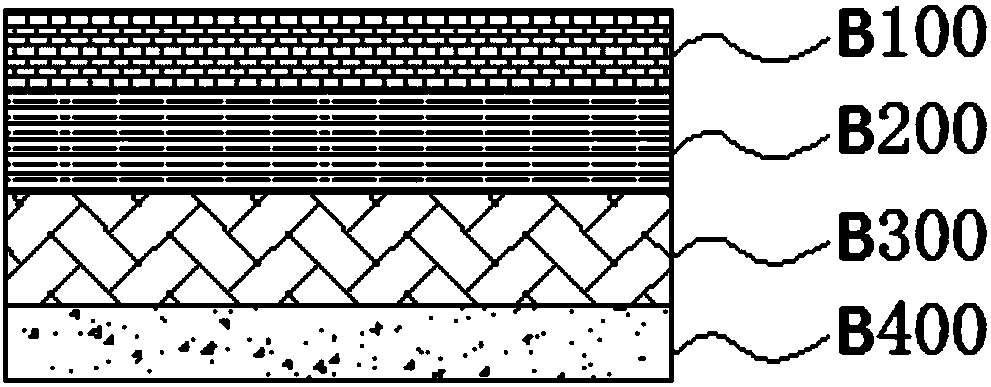

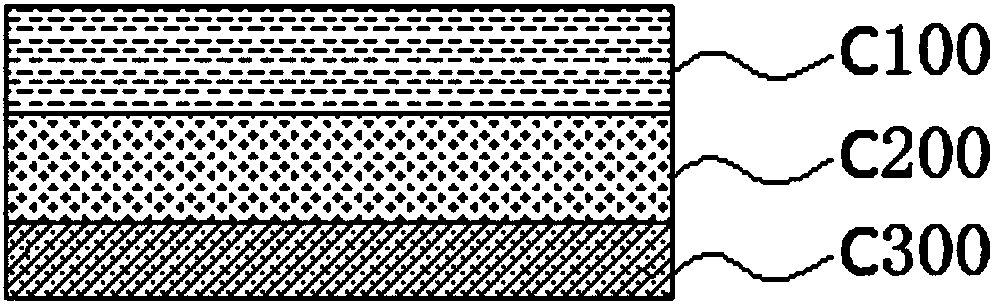

[0052] Embodiment: a kind of ultra-thin white covering film, as Figure 4 As shown, it includes a white ink layer 100 and an adhesive layer 200, and the white ink layer 100 is located on the upper surface of the adhesive layer 200;

[0053] The total thickness of the white ink layer 100 and the adhesive layer 200 is 4-50 μm, wherein the thickness of the white ink layer 100 is 1-25 μm, and the thickness of the adhesive layer 200 is 3-25 μm ;

[0054] The white ink layer 100 includes at least one of a composition of an organic pigment and a white filler, an inorganic pigment and an organic pigment, the inorganic pigment is a white pigment or a gray pigment, the organic pigment is a highly transparent polymer, and the The white filler is at least one of silicon dioxide, titanium dioxide, aluminum dioxide and aluminum oxide;

[0055] The hardness of the white ink layer is HB-5H, preferably 2H-5H;

[0056] The surface gloss of the white ink layer is 0-50GU (60°), preferably 0-5G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com